The past, present, and future for sustainable aviation – Flight into Sustainability

The push to make commercial aviation sustainable is well underway. While commercial aerospace operations account for only about two percent of global greenhouse gas emissions, there is a concerted effort across the aerospace industry to achieve net zero emissions by the year 2050. Companies have begun exploring many new technological solutions, such as alternative propulsion systems and airframe designs, yet there are still underlying, industry-wide challenges that can make the transition to sustainability difficult.

How the aerospace industry is going to overcome these obstacles and achieve its goal of reducing greenhouse gas emissions are the topics of the Flight into Sustainability video series. In its first episode, hosted by Todd Tuthill, Vice President of Aerospace and Defense for Siemens Digital Industries Software, the series identifies the fundamental challenges behind making aviation sustainable, what the industry has done so far, and where it still needs to go.

Cost and scale

Creating new technologies and designing new aircraft that emit less greenhouse gases has its own difficulties, yet perhaps the most concerning challenges come from the costs of transforming such a massive sector. Take the amount of flights that occur on a regular basis. According to Todd, approximately 45 million commercial aviation flights happen every year. That translates to about five billion passengers every year, carried across 120,000 flights every day. Around 30,000 aircraft are required to keep up this scale of aviation across the industry. Not only is that a lot of aircraft to make sustainable, but also a lot of new infrastructure would need to be built to support new propulsion systems.

In terms of covering the transition’s cost, the aviation sector currently generates about one trillion dollars in wealth per year, with some estimated growth over time, yet that might not be enough to cover the costs to make aviation sustainable. Todd states that estimates for the transition to net zero emissions from now to 2050 range anywhere from three to five trillion dollars. The one trillion dollars per year sounds like it might be enough to grow over the 25 years and cover the costs, but the actual profit margins for aviation per year is only about 26 billion dollars. By 2050, Todd says, the industry will likely make only two trillion dollars on profit, falling short of the three trillion minimum for the transition to sustainability.

Making aviation net zero is still a crucial goal for the sector’s future, of course. Companies will just also need to find a way to navigate the costs as they make their transition.

Lessons from history

Even when sustainability was not a priority in aircraft design, however, aviation companies have already made strides in reducing emissions, for greater efficiency if nothing else. This was accomplished largely due to innovations in aerodynamics, aircraft weight, and propulsion. Todd points to a couple specific examples:

- Newer aircraft now incorporate winglets and high-aspect ratio wings, enabling aircraft to burn less fuel when flying.

- Airframes are now mostly made from composites, which are lighter yet stronger than traditional materials.

- The introduction of digital control systems that require less wiring have also helped reduce weight.

- New engines now have better bypass and pressure ratios that increase fuel efficiency, resulting in fewer carbon emissions.

Compared to the solutions being discussed today, these changes in aircraft design have not been as expensive or fundamentally transformative. Yet they certainly played a role in reducing aircraft emissions and show the tangible effect designing aircraft with sustainability in mind can have.

Looking toward the future

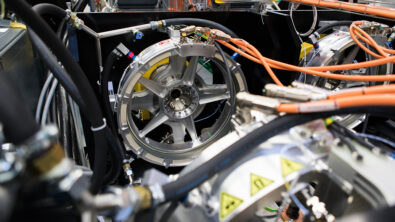

Despite these innovations, however, the core aspects that have guided commercial aircraft design for decades still have yet to change. Airframes are still the traditional “tube-and-wing” shape, and despite more efficient engines, fossil fuels are still the source of power. Until these fundamental aspects of aircraft design are changed, according to Todd, meaningful strides toward sustainability will continue to elude the aerospace industry.

These more significant changes are likely to be the more expensive factors of the transition to sustainability, alongside new infrastructure necessary to support changes such as alternative propulsion methods across commercial aviation. Balancing the development of continued innovations in aerodynamics and propulsion with the projected costs will be the ultimate challenge for aviation companies.

Fortunately, Todd will be diving deeper into how companies can achieve this balance in future episodes of Flight into Sustainability. Topics will include technological solutions such as electrical and hydrogen propulsion, new ideas for airframes, as well as wider-reaching methodologies such as digital transformation to better optimize design priorities. Stay tuned to find out more on how aviation can be transformed for a greener, more sustainable tomorrow.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.