Expanding AAM Range with Better Batteries Part Two – Transcript

In this episode of Talking Aerospace Today, Todd Tuthill and Puneet Sinha highlight the ways digital transformation can optimize advanced air mobility designs and the batteries that power them.

Patty Russo: Greetings, and welcome to Talking Aerospace Today from Siemens Digital Industries Software. I’m Patty Russo and I’m responsible for our global aerospace and defense marketing vertical here at. Today, as promised, we’ll pick up the conversation on the need for increasing range and advanced air mobility, a burgeoning segment in our industry. Previously, we also covered the elements of battery technology that must be improved to achieve expanded range. Joining us today, as always, is Todd Tuthill, Vice President of Aerospace and defense here at Siemens, as well as our guest Puneet Sinha, our Head of Global Battery Industry.

Patty Russo: Last time we ended with Puneet’s insights on battery safety. So let’s pick up on that topic. I’ll start with a question for Todd. Todd, I want to direct the next question to you. You’ve spent your career designing redundant control systems to make aircraft safe. Relative to the complexity that Puneet just described, what are some unique design considerations that need to be addressed with respect to the potential failure modes that Puneet just talked about?

Todd Tuthill: Great question, Patty. Let’s look at the design of the control system in AAM again. We talked about advanced air mobility. It’s an electric powered aircraft, an aircraft powered by batteries, and those batteries are connected to multiple rotor blades. And when we think about the specific aspect of creating safe aircraft and designing aircraft to be safe, because that’s certainly one of our major goals here, we try to avoid things called single point failures. Single point failures in aerospace and aircraft are really, really bad things because in the control of it, they can cause really bad things that may cause loss of control of the aircraft or loss of thrust.

Todd Tuthill: So as designers are looking at aircraft, be it conventional aircraft or AAM or even helicopters, they’re looking at how to eliminate single failures that can cause, again, lack of controllability or lack of thrust because both of those probably mean that the aircraft you were flying safely in isn’t flying safely anymore. So you think about how that works and if I look at a conventional aircraft and how they’re power and how they’re controlled, a conventional 737 or A320, they have engines that are controlled by jet fuel, two of them, and they provide thrust, and those engines then provide power for the control system. The things on the wings that move the ailerons, the elevators, the flaps, those kinds of things. So there’s multiple copies, multiple things, redundancy in how that works.

Todd Tuthill: If you look at the way redundancy is designed in advanced air mobility aircraft now, compare maybe a Wisk Gen 6 or an Archer Midnight to a helicopter, helicopters got one set of roller blades. Those advanced air mobility, the modern ones designed by Wisk and Archer right now, and several others, if you look at the whisk in the Archer, there’s 12 sets of rotor blades, not one, but 12 around the wings. That’s not an accident. That was done very deliberately, added redundancy for safety. Because while I have no inside knowledge of the design of those aircraft, I’m very confident just by looking at them that you can lose a few of those rotor blades and that aircraft will still operate safely. That’s the idea of redundancy.

Todd Tuthill: And you say “What does that mean to batteries and the technology we’re talking about, Todd?” Well, what that whole thing does is it’s this play on safety and because we’ve got to be safe, we’ve got to be redundant, but by doing that, we really increase the complexity of the electrical design of the aircraft. We increase weight and we increase cost, and of course if I’m adding more weight for more rotor blades that means I’ve got less weight I can allocate to cargo and to passengers, things that are going to make money and help me monetize and that’s why that that balance is so important when we think about safety and redundancy and batteries and complexity. And you know it, it may make your head spin. But from the aspect of a design engineer, that’s where the fun’s at.

Patty Russo: Which brings me to a great next question that you probably would guess that I’ll ask following what you just said. When we talk about complexity, it always drives my brain to think about the technology used to design these complex products. So Todd, how can digital transformation technology help the design of batteries to ensure single failure is eliminated and ensure safe flying while at the same time improving AAM range?

Todd Tuthill: Yeah, I want to be Goldilocks. That’s what I want to be and say. Goldilocks. Yeah. Think about Goldilocks’s porridge. She wanted it. She didn’t want to be too hot or too cold. She wanted to be just right. She wanted to it to be optimized. And when I think about the design of aircraft, and specifically the interesting design considerations with respect to advanced air mobility, there’s a real optimization that needs to take place. You know, as I was saying in the last answer, I could go for all the safety all day long. I could not have 12 rotors. I could have 20 and I could have seven different battery packs. And eventually this thing gets so heavy it can’t even take off. Or I could say how I can’t afford 12 rotor blades. I need four because that’s all I can lift. Well, maybe that’s not safe. And there’s a sweet spot.

Todd Tuthill: There’s an optimization and I’d like to not have to build five thousand copies of an aircraft design and fly it to understand where’s the sweet spot. Where’s Goldilocks’s porridge at? I want to find Goldilocks porridge. The optimization point I want to find that digitally in a digital twin before I ever fly it physically. And you can look at those kind of Goldilocks playoffs, your trade-offs, I can look at those with respect to redundancy. I can look at them with respect to aerodynamics. I can look at them, we were talking earlier about how much battery do I need? Can I be profitable with the energy density I have today? Or do I need to double it before I’m really going to make money?

Todd Tuthill: And you can do those trade-offs in digital twin. How far can I fly? How safe can I be? The what’s the optimum lift? That’s the real benefit of the digital twin when it comes to aircraft design and making all those trade-offs and optimizations before I fly, because it’s orders of magnitude less expensive to make those changes, find those mistakes, correct those things digitally before you go build it physically. And I’m going to guess if we think about Puneet, you know I’m thinking about the aircraft at a system level, Puneet can probably talk about that very specifically at the battery level too.

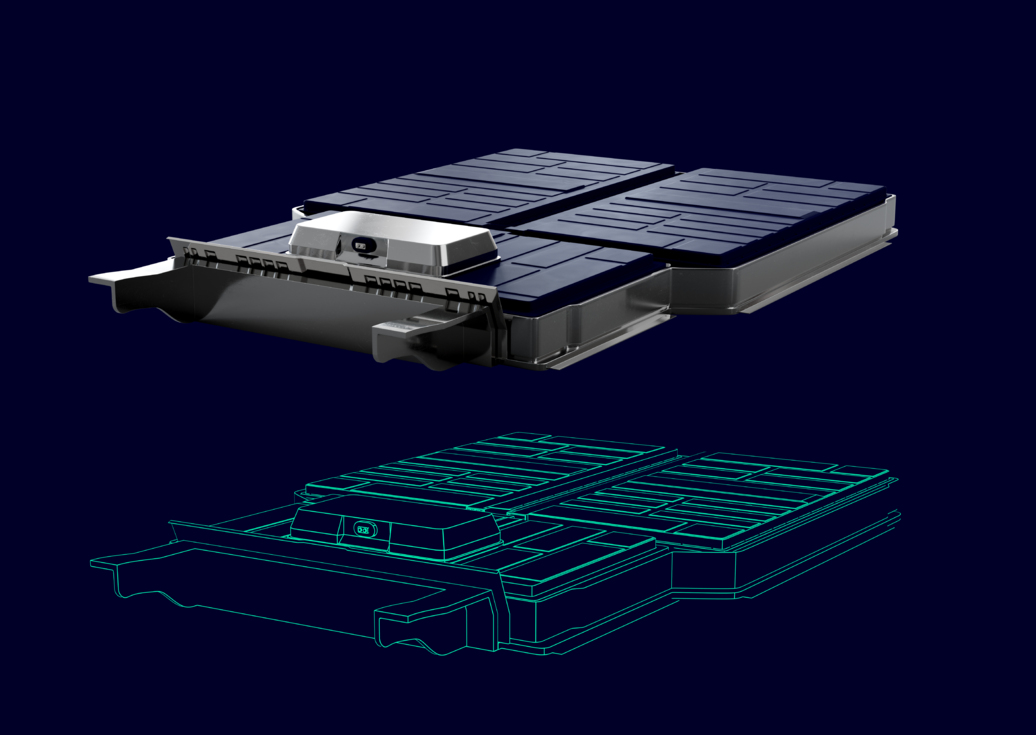

Puneet Sinha: Absolutely, Todd, but I’ll definitely give a shout out to the way you described. It. That’s exactly what we are looking at in in the world of batteries. And the point that you made, I’m just going to echo that for our audience, batteries are never and should never be designed in a silo. It is always part of a system. So what are the system requirements? It has and must have strong implications of design, architecture, materials, everything that you have to use in battery. But if I look at from just from the battery perspective, you can ask, and I think it’s a valid question, the amount of R&D and the amount of investment that is going in battery. Why are we still talking about battery safety? Why are we still talking about it? Is this battery going to last or is it going to be safe?

Puneet Sinha: And the reason is the world of battery is a bit different than some of the previous technology like the IC engine or these more traditional technologies. And the reason is the domains of chemistry, thermal, electrical, electronics, software system, these domains interact really strongly when you’re designing or manufacturing batteries that were either very weak, these interactions were somewhat weaker, or in some cases was not present when you think of combustion engines. As an example, I can change a material, not even the active material that that holds lithium. Even the glue that holds this material together, what we call binder, I can change that material. Minor change. It can have huge implications on not only in the performance but also life and durability. Safety.

Puneet Sinha: So one change a material scientist can try to make at a microscopic level has huge implications on life and these things may not be just obvious when you’re designing the battery and testing them at the beginning of life, it may have implication of what’s going to happen to a battery five years down the line. In the same way, the way where the battery needs to go and sit in which system will have a strong implication on your great battery whether that will work or not. What is the charging rate? What are the duty profile that that it needs to satisfy weight requirements? You know all of those things have a strong implication on what kind of cell design, electrode design, materials you choose.

Puneet Sinha: So when you look at this world, you cannot, people have tried to optimize things in silo. What is the best material? What is the best cell design? What is the best system design pack design? It doesn’t work. It overengineers, or many times leaves a lot of those things that has a wrong implication on life and safety down the line. And that’s where this digital transformation, this digital twin, digitalization, comes into play, allowing engineers not only the electrochemists, but also the design engineers, manufacturing engineers, system integrators, all to work together without becoming an expert in every domain.

Puneet Sinha: How they can work seamlessly to make sure that right battery design, it is sized correctly for the right application for the kind of charging that is going to be available, the kind of redundancy the system needs to have and the overall architecture, electrical architecture. So it is very, very critical. Absolutely necessary now if you want to have a safe, durable system with battery as your power source. You need to account for all of this.

Patty Russo: Yeah. So considering the multidisciplinary approach to design, obviously key in that acceleration of digital transformation technology. So that leads me to a question we’re getting close to the end of our episode, but I have one more question before we wrap things up and that is to Todd. Where are we in the industry? We’ve talked obviously about the level of complexity of the AAM aircraft, the complexity increase related to adding the battery power. So where is the industry in terms of developing AAMs and are you in a position to do you care to project how soon you think we might see certification? There’s obviously lots of startups dabbling in this, and that’s probably not the right word, but just curious and I’m guessing the audience is thinking the same thing. Where is the industry and how soon do you think we might see actual certification?

Todd Tuthill: So give you a couple of data points. If you roll the clock back a year, 18 months or so, we just finished the Paris Olympics and the Paralympics are on our mind. And if I go back to 2023, 2022, Volocopter had made a bold statement. They said we are going to certify, and it’s a type service, what it’s called. It’s an allowance by the authorities to allow that aircraft to operate with paying passengers. Okay, that that’s a final type cert. Volocopter committed to have that in place for a two person aircraft to make a splash at the Paris Olympics. Unfortunately, Volocopter didn’t make it and the reality is none of the advanced air mobility companies have actually got to the point where they’ve received a final type cert yet. There are many, many companies that have been flying the aircraft and under a test certification for a long time. None of them are there.

Todd Tuthill: As you look at the different people in the industry, some of them are predicting 2025, 2026. I’m very comfortable to say that in the next couple of years I think we’ll see a number of these companies getting their initial type cert, starting to fly. And I’ve made the prediction that by, you know 2030, we’ll be able to go to a major city in New York or Paris or London and schedule one of these aircraft, and I think that’s true. I think by the end of the decade we’ll see that. But so far no one’s quite there yet. A number of companies are getting pretty close, and I think that’s the topic of our next episode, certification. So we’ll get into that deeply on maybe our next episode.

Patty Russo: Nice. Yeah. So, lots of things to consider. Puneet, I’d like to prompt you. Is there anything that you’d like to share before we wrap things up today, either commenting on the complexity or safety or the process to certify before we wrap things up, anything you’d like to add?

Puneet Sinha: Well, I will. I’ll say three things. One, I really enjoyed coming on this podcast. Having the conversation with Todd and you learned a lot about the complexity of these systems, and hopefully was able to give some insight into the world of battery and what it means for air transportation. And second point I will mention when the companies, the kind of companies Todd was referring to, I’ll encourage them to look at the journey of automakers who have gone through this journey of electrifying their vehicles with batteries. The world of eVTOL doesn’t have to repeat some of the mistakes that that has happened in the automotive world as they were learning how to work with the complex electric system and batteries. The learnings from them, be it on the engineering side, manufacturing side, usage of those batteries can be leveraged by the advanced Air mobility ecosystem.

Puneet Sinha: And third point, Todd, I would love to go on an eVTOL ride with you someday and I’m going to ask, as you said, by the end of this decade, it’s going to be available. Perhaps you know not that far in the future, if we can take a ride together and perhaps you and I can work together to make that end of the decade commercialization of eVTOL a real possibility. So something for both of us to look forward to.

Patty Russo: So Todd, do you have anything to add and, or it sounds like an invitation for something interesting in the future?

Todd Tuthill: Sure. Thank you, Patty. And Puneet, thank you so much for coming on the podcast. I really appreciate your insights, and I appreciate your invitation. I think that’s a great idea. It’s a deal. You know, people ask me all the time about aerospace and technology. You know, is it safe? Would you fly on it? And when it comes to advanced air mobility vehicles? Absolutely. I can’t wait to fly on an advanced air mobility vehicle and Puneet, I would love to take up your opportunity, take up your invitation. We’ll certainly make a plan out of doing that, so that’s the first thing I’d say. The second thing I’d say is I hope when our listeners listen to this, you know, we’re talking about obstacles to overcome. That’s kind of the negative side of maybe the coin, but I want us to also look at the positive side.

Todd Tuthill: There are such incredible technologies being put together and such an incredible opportunity and time in the world of aerospace engineering. I don’t think there’s ever been a time in history other than maybe the Apollo program when we were trying to put someone on the moon the first time. But just such an incredible time for engineers and technology and cool things going on. And that’s certainly true in advanced air mobility. So don’t just look at these as problems. Look at these as opportunities to come up with really great engineering, innovative solutions. And the last thing I’ll finish that we didn’t have time to talk about it, but I wanted to. I thought it was worth mentioning. I talked at the beginning about Cosmic Aerospace and technology that had happened just in the arc of recording this podcast relative to the aircraft. But Joby had a pretty significant event as well in the past few weeks in the process of this podcast.

Todd Tuthill: Joby flew an advanced air mobility vehicle on hydrogen and fluid for several 100 miles, so there’s just so much opportunity, so much things to talk about. We didn’t plan a hydrogen episode, but that was too much for this one. But I just wanted to do a shout out to Joby as well for the really incredible accomplishment they had in flying their aircraft several 100 miles on hydrogen. So maybe in the early 2030s we’ll see hydrogen-powered AAMs too. That would be interesting as well. But thank you, Puneet. Thank you for Patty. It was a pleasure. Always fun to come on the podcast to talk about cool things in engineering and how digital transformation can help.

Patty Russo: Yeah, lots of great insights today in our discussion. So thank you for bringing together the expertise from your respective industries. And Puneet, thank you for joining us. And finally, thank you, of course, to our listeners for joining us today as well. We hope you learned something new and maybe raised some additional questions about improving operational range for AAM and we do hope that you’ll join us for our next episode as we talk more about the challenges of the AAM and how digital transformation technology can help accelerate the development of these innovative products. I’m Patty Russo and we look forward to having you back next time on Talking Aerospace Today.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.