Expanding AAM Range with Better Batteries Part One – Transcript

In this episode of Talking Aerospace Today, Todd Tuthill and Puneet Sinha begin exploring the need to increase range in advanced air mobility (AAM), and how that could be accomplished with better battery technology and digital transformation.

Patty Russo: Greetings, and welcome to Talking Aerospace Today from Siemens Digital Industries Software. I’m Patty Russo and I’m responsible for aerospace and defense marketing vertical here at Siemens. Thank you for joining our conversation. Today, we continue our deep dive into the four key challenges to overcome launching advanced air mobility, a new classification of aircraft that includes vehicles such as air taxis. So far we’ve covered implementing autonomous flight with insights from the automotive industry. And we’ve learned about considerations to build the infrastructure needed to support AAM.

Patty Russo: Our topic today will cover why increasing the operating range of AAM is important and how companies can address this with technologies such as batteries and by accelerating the adoption of digital transformation technology. Joining us, of course, is Todd Tuthill, our Vice President of A&D for Siemens. Welcome back, Todd.

Todd Tuthill: Hey, Patty. Great to be back. Going to be fun today. I’m really excited about this podcast. We don’t, we talk more mechanical things I think a lot on this podcast, and that’s just the generic way inside of aerospace today. We’re going to talk about electronics. We’re going to dive deep into some electronics. It’s going to be a lot of fun. Going to get into some real engineering. Can’t wait to do it. Good to be back.

Patty Russo: And to provide that insight and expertise, I’d like to introduce a special guest today, Puneet Sinha, Global Head for Battery Industry here at Siemens Digital Industries Software. Welcome, Puneet.

Puneet Sinha: Thanks for having me, Patty and Todd, and I am super excited for today’s conversation. I will talk two things that I’m very passionate about: batteries and flying. So yeah. Awesome.

Patty Russo: Well, we’re glad you’re here and I’m going to go ahead and start with Todd, a question for you. We’ve covered a lot in our previous episodes. Can you give a couple highlights from those episodes and then introduce why range is so important for AAM and such a challenge to address?

Todd Tuthill: Certainly, Patty. We’ve been talking about the arc of advanced air mobility in this podcast. We’ve talked about autonomy, had a great series of podcasts there. Then we talked about infrastructure and the challenges of overcoming infrastructure. And the goal here is to really talk about what are the things that the advanced air mobility needs to overcome, the challenges to overcome, to really become a viable profitable industry, and certainly those two are challenges. The one today is very, very key if you want to make money in the advanced air mobility space and that’s range. How far can these things fly?

Todd Tuthill: And in the setup podcast I did initially, I had said the basic range of these electric aircraft is 100 miles and that’s true for advanced air mobility. But just to be clear, the technology in this space is changing so fast, and I just want to do a shout out real quick to a company. I met, the CEO of a company called Cosmic Aerospace and, you have my permission to pause this podcast right now and Google it. They’re an incredible company based in Colorado. Meadow, they’re building an electric all electric aircraft. That’s not an AAM. It’s more of a regional aircraft that will carry 24 passengers 1000 kilometers on just batteries. Now we’re not going to talk about that specifically, but I don’t want to leave the impression that all electric aircraft are limited to 100 miles.

Todd Tuthill: That’s not necessarily true anymore with the entry of Cosmic. They think they’re going to have their aircraft in service by the end of the decade. I really hope that’s true, that it’d be a wonderful thing, but just wanted to call them out and then get back to the range discussion we’ve had on advanced air mobility, a different kind of aircraft that seats, you know, as we said, four to six people has a range of about 100 miles with the current battery technology today. That’s what things we’re quoting and we’ll talk a lot about that technology and what that means. But I just wanted to set up the discussion before we start about what it means for an aircraft to have 100 miles of range. What can I do with it?

Todd Tuthill: Well, I can land in LAX. If I land in LAX and we all know about the bad traffic. If you’ve ever been stuck on the 405 in LA in rush hour, you know what that’s like, or even at 2:00 in the morning. But I land in LAX and I want to get to the beach and how fast can I get there? Well, right now, not very fast if I’m in a car, but if I had one of these cool advanced air mobility vehicles, I could get there quickly in the afternoon and time to take in the beach before I have dinner, maybe. And if you think about 100 miles means to LAX, 100 miles I can get from LAX, I can get to Santa Barbara, I can get to San Diego. So within 100 mile range, I can cover the entire scope of the LA metropolitan area.

Todd Tuthill: But I couldn’t do something if I landed in London and I wanted to quickly get to Paris, couldn’t get there, or if I was in Paris, I wanted to get to Berlin. So that’s the kind of thing we’re talking about generally within a metropolitan area, but not necessarily even between large cities in Europe. That’s what we’re talking about with the range we have today, and then we’ll talk, you know, to also about where, where we could go if we could double or triple the range. But those are kind of the economic thoughts that we’re having today, and could this industry be profitable at 100 miles? A lot of people say yes, some people say no.

Todd Tuthill: But I’m really looking forward to insights from Puneet to what it’s going to take to increase the range of these aircraft from the current 100 miles to two or three hundred and open up all kinds of possibilities where I could then, you know, fly from London to Paris or from Paris to Berlin, and one of these ones I land in. So that’s kind of the setup. That’s what we’re talking about. How does range relate to profitability? And we’ll get into other things about certification and safety as well. So that’s the setup. That’s why this is so important to this industry.

Patty Russo: Outstanding setup, Todd. Thank you. Puneet, I’m going to ask my first question of you. It’s somewhat fundamental, but obviously critical to the discussion around power and range for the AM sector in the industry. Can you share please how batteries work and what considerations for design are needed to improve the range of batteries to power the AAM craft?

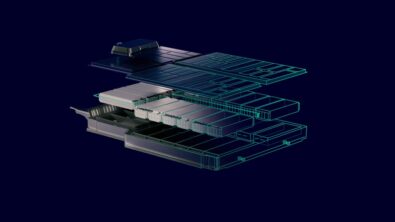

Puneet Sinha: Sure, Patty. In battery you have two houses, we call them electrodes, cathode and anode, and lithium shuffles back between these two places. And the way it goes through is a medium called electrolyte, which in today’s state of hard battery is a liquid. Currently, the materials that are used, they have limited capacity of how much lithium they can hold and how fast that lithium can go back and forth through that electrolyte. How fast lithium can go through that electrolyte determines the power, because the faster they can shuffle from one electrode to another electrode gives you the power. And how much lithium those electrodes can hold gives you energy. And that’s how battery works.

Puneet Sinha: Now, as Todd said earlier that today if you look at eVTOL there roughly there are 200 kilometer range in that respect, close to 100 miles, and that is pretty much limited by how much battery capacity there is to power them. In order to increase the range of battery, what is needed is new chemistries that can hold more lithium and then the other thing that is needed is a better medium. Today it is electrolyte which is made of certain solvents and liquid. Can that electrolyte be made better so that lithium can go back and forth faster and that will give you more power? There’s a lot of work going on in the industry to do that. But before I go and talk about what more is needed, it is very important to look at what has happened and I want to spend couple of minutes for the audience.

Puneet Sinha: Lithium ion battery was first commercialized in 1991 by Sony. Back then it started with consumer electronics like, you know, cameras and phones. But it was around 2007, 2008 time frame when these lithium ion batteries made it to cars for the first time in a commercial way. And that was the time, you know, I remember even as it was yesterday, when GM, when I was at GM, and GM was working on Chevy Volt and Nissan Leaf, Tesla Roadster. So those were the cars, you can say, the first wave of lithium ion battery becoming part of vehicles. Commercial vehicles. Fifteen or so years have passed. In these 15 years, battery energy, how much energy you can pack in one kilogram of battery has increased three times, and the cost of battery has come down 90 percent.

Puneet Sinha: I’m going to repeat, cost has come down in the last 15 years by 90 percent. Energy density, that means how much energy you can pack in one kilogram of battery, has gone up three times. And that has happened mainly because of all the innovations and these chemistries for anode and cathode has happened, how much innovations companies have made in improving electrolyte designs. And that’s what we are looking, that’s where we are today. And that’s why when you look at Tesla Model S today or other, BYD and many other companies who are offering close to 300 mile range today.

Puneet Sinha: It is the reflection of that. That’s a good point where we are in the automotive industry, at least, you know, where the electric vehicles have started making an inroad in its adoption by consumers. When it comes to air transport, it’s absolutely a different ball game, and to me in the world of air transportation, we are pretty much at the, we are pretty much where we were with electric vehicles around 2007, 2009 time frame. Just about to start. Battery is good enough to get started but a lot more needs to happen before it can be part of the kind of transportation Todd was referring to.

Todd Tuthill: Wow, Puneet, that’s some great information, and I could say all kinds of things to unpack that. One of the things I guess I’ll ask you if you think about the, you know, the incredible numbers you talked about, 3X in energy density over the past 15 years. At what point do you think the laws of physics are going to flatten that out? Or maybe they already have? You know, we’re going to see another 3X in the next 15 years? Is that slowing down? What can we expect for energy density, do you think?

Puneet Sinha: Yes, great question, Todd. We are far away from reaching the limit of the laws of physics. For example, one of the big things that battery manufacturers are looking to do is how they can change those materials for anode and cathodes. Today, state-of-the-art roughly for battery cell lithium ion cell, we have around 250 Watt hour per kg energy density. That means one kilogram of battery cell has around 250 Watt hours of energy. But advancements are being made that companies like CATL, which is the largest battery manufacture in the world, they have announced last year that they are working on a battery, what they call condensed battery, that is going to double that energy density.

Puneet Sinha: There are other companies in the same way who are looking to improve those material chemistries, cell design, how those cells need to be packed together to make this happen. And every analysis that I’ve seen the companies in the eVTOL world, the battery manufacturers that I’ve talked, there are two magic numbers. One is if you’re looking for eVTOL, intercity transportation less than 200 kilometer range, let’s say two ton of weight category for those eVTOL. Today’s technology is good enough, of course, you say, maybe another 20, 30 percent improvement in the energy density will make it more commercially viable to have that intracity air transportation, what Todd was referring to going from LAX to be so that you don’t have to get confined by the travel congestion.

Puneet Sinha: But if you are looking for travel from London to Paris or again, you can call it, let’s say, even in a more broader range, let’s say closer to 2000 kilometers of travel in a small aircraft, it needs to be doubled. The energy density there today is it needs to be doubled for that to be even, viable, technically viable.

Patty Russo: So, Puneet, getting the most efficiency from the battery and maximizing use obviously are critical, but let’s shift the topic just slightly and let’s talk about battery health, and what, tell me what specific issues could cause battery malfunction while it’s powering an aircraft? Obviously something pretty critical that people might think about before they decide to embark on a journey in one of these AAM.

Puneet Sinha: Again, great question, Patty, and I’m glad you brought up that topic. You know, one thing that I like about battery and I always say, is that batteries are exactly like humans. They love to work in the environment which is comfortable for us, from 10°C 35°C. Known as the sweet spot for batteries. If you go higher in temperature, our efficiency also goes down. You know same is for batteries. Battery will degrade much faster. If the temperature is very low, let’s say below 0°C, you will see the performance of battery will also go down and we start having some issues.

Puneet Sinha: If they are asked to operate, charge or discharge in those colder temperatures, that has implications on the life. So temperature is a key factor, but not the only factor. The other factor is voltage at which a lot of these batteries are kept, and perhaps an easy way to associate with that is think of your laptops. Most of the time our laptop is always plugged in, always charged all the time, and we all may have experienced this. That the battery life in our laptops it tanks very quickly all of a sudden. Couple of years and you will see rapid decrease in how long your laptop is going to last if it is not connected.

Puneet Sinha: And the reason is when it is always connected, the voltage of the battery is high and then the some of the chemical reactions or side reactions that are happening inside the cells, they are accelerated if batteries kept at higher voltages. So the operating range in which batteries operate in voltage-wise, and the temperature in which battery can be kept, those are the two of the biggest factors that determine how long the battery is going to last.

Todd Tuthill: So, Puneet, I think what you talk about is very, very germane to the life of batteries and the way batteries are used efficiently in aircraft, how long they’ll last. But another issue I think about with respect to aerospace and aircraft is safety. And can you talk about how batteries fail and how that safety impact of their failure might be different between cars and aircraft?

Puneet Sinha: Absolutely, Todd. I can’t stress enough how critical battery safety is for any application where the system has to go in air. If it happens on the road, it’s always bad, but at least you can pull over. It will be very tough to do that when you are in the air. For battery safety, again determined by the those two factors that I mentioned before, if temperature is not controlled, the temperature will go high. Some of those side reactions will start increasing and many times that can lead to some very bad events. And these batteries, lithium ion batteries, they have a lot of energy packed in them.

Puneet Sinha: So if I put perspective, when those sad reactions happen for a cell, if it goes into their thermal runaway, it is equal the amount of energy it releases is same as approximately six grams of TNT being blown. So you are looking at a lot of energy that is ready to be released and it can lead to an explosion or those fumes coming out. So it is very critical that the temperature of battery is controlled very well. And then the other thing is that every cell in the battery, and by the way I must have mentioned earlier, when we talk about battery and the application like aircraft, there is not one cell you are looking at hundreds or thousands of cells.

Puneet Sinha: Each cell temperature and voltage must be monitored and controlled because you do not want even one cell to go into bad reaction that can propagate in many other cells that are in a battery pack. It’s very critical. There are a lot of regulation, very strict regulation, not only, that every battery manufacturer has to pass for their cell safety testing, but then these regulation also need to be met at a system level. And Todd, perhaps FAA regulations you can touch more upon. Of course, it’s a big standard in the air transportation and very critical.

Patty Russo: Wow, there is so much to learn about battery safety. Thank you for your expert insights, Puneet. With that, we do need to wrap up our discussion for today, but don’t worry, we won’t leave you hanging. We’ll conclude this discussion in our next episode. Once again, thank you, Puneet and Todd. Thank you again for your contributions today. And as always from all of us here at Siemens, a sincere thank you to our listeners for tuning in. I’m sure you can take away some great insights. We look forward to catching up with you again next time on Talking Aerospace Today.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.

Comments

Leave a Reply

You must be logged in to post a comment.

Interesting discussion on AAM range! Battery tech is definitely key. Digital transformation can optimize power consumption too. Have you considered the energy density challenges? Perhaps exploring novel materials beyond lithium-ion is warranted. It’s like needing to strategically drop blocks in Block Blast to maximize space!