Sustainability at scale – The Battery Podcast S01E02 Transcript

Here is the full transcript of S01E02 of the Battery Podcast, with Dr. Markus Gräf, Dr. Christian Offermanns, and Dr. Hannes Schmueser. Each take a few minutes to talk with our host Marc Deyda. Hit play to listen along if you’d like, but lets dive into the discussion.

Nick:

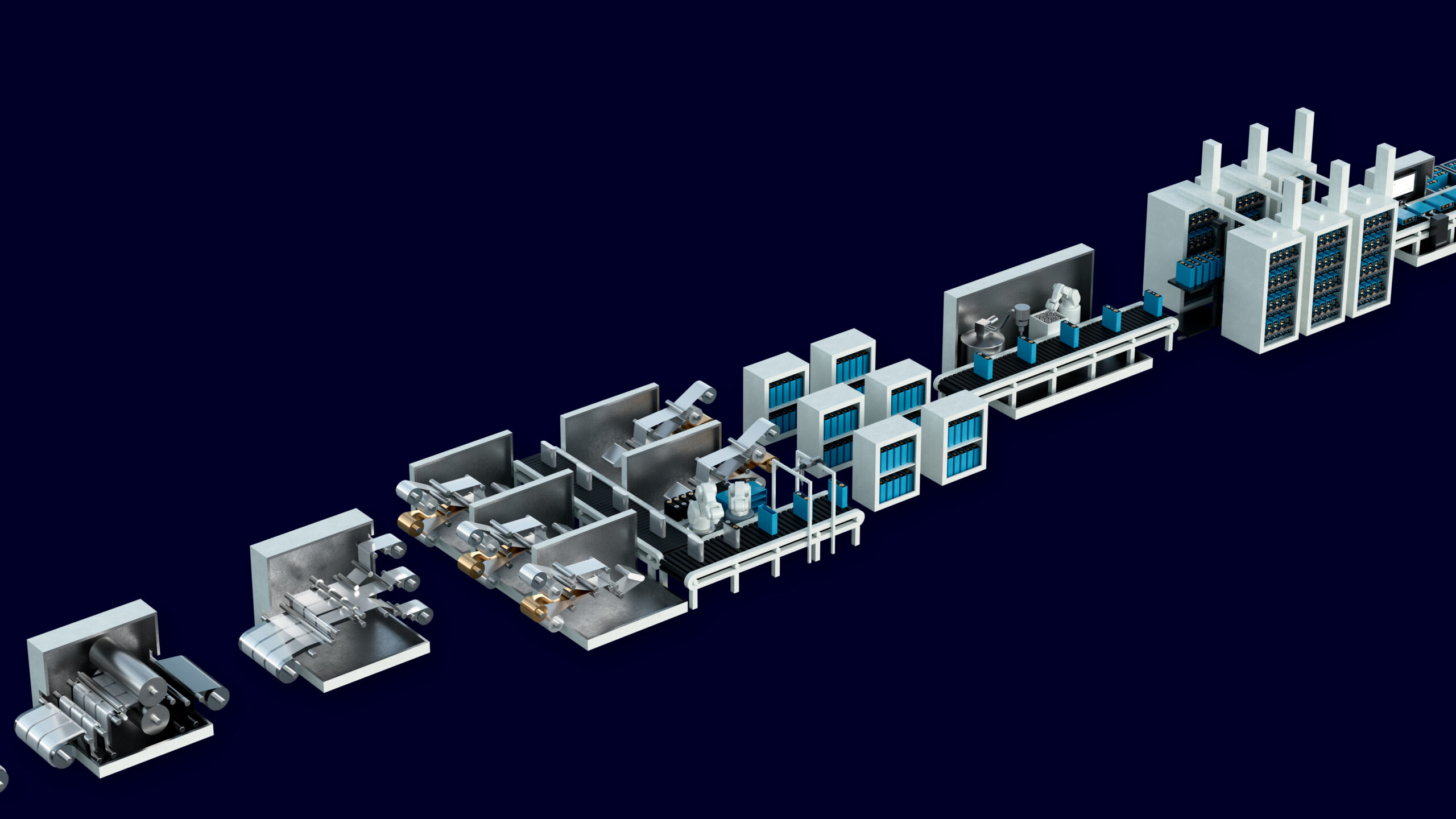

Hello and welcome to The Battery Podcast from Siemens Digital Industries, where we talk about challenges, technologies, and solutions for the battery industry. In our first episode we let you know where you would find us in the coming months and one of those events was the Battery Show Europe. For those that couldn’t make it, we were able to sit down with a handful of experts to get their thoughts on the industry’s progress from the show floor with our series host Marc Deyda.

Here is Marc’s chat with Dr. Markus Gräf, the COO of Cellforce Group.

Marc:

Hello, Dr. Gräf. Happy to have you here on the Battery Show and thanks to join this panel discussion, it was really great. And I have just two additional questions that we would record here in the podcast. The first one would be, we have just confirmed the collaboration together. What are your views on that?

Markus:

I think this is now a perfect match, as we started with Siemens for I would say more than one year. And we found out that Siemens has so many software components which we can use and we are already using. We have installed the product lifecycle management, we are team viewer and now we decided to go with the op center. So the golden triangle is for us the most important thing, to be ready for the future. The golden triangle with SAP, Siemens team center and the op center. And all this stuff behind with the facility management we also gave to Siemens, we are on the way to make really a digital transformation 4.0 reality.

Marc:

Great to hear that. Thank you. So within the production process, there are some faults sometimes. How do you ensure this early fault detection?

Markus:

Well, that’s for us a main topic as I described on the panel discussion. For the cell industry, it’s always problematic. You are producing with the coating a foil and one and a half week later, you know if it’s good or bad. So fault detection, especially in the area of coating, is crucial for us as we spend a lot of money in the bin in the worst case. So the collaboration we are doing here with Tour and Siemens, how to get really the coating process more stable and more predictable with less waste. That is the main focus now.

Marc:

Perfect. we have to wait for us. So happy to have you here and still enjoy the Battery show successful VIP event and yeah, thanks.

Markus:

It’s huge. Thank you very much for the time.

Nick:

Our next guest, Dr. Christian Offermanns, is the chair of production engineering of emobility components at Aachen University

Marc:

Christian, happy to have you here and thanks to attending the panel discussion as well. So on the battery show here in Stuttgart. I will just do two questions to you shortly. Short answers, crispy. The first one would be: which production site factors need to be considered when planning and implementing new factories to increase the energy efficiency of the factories.

Christian:

very likewise. Very happy to be here today. I think when you are planning a production site, you have to have in mind what are the costs in the end, so Opex as well as Capex. To plan on the long run, I believe that especially Opex are very, very important and the main factor, in my mind, is to reduce the energy that you need to produce the batteries afterwards. There are different factors that you have to have in mind there. I think the main reasons for energy consumption are especially electro production, we see that the drying process does cost a lot of energy. We see that the clean and dry room is an important production scale where a lot of energy is consumed as well as formation. If you are planning the whole production line, you have to have in mind that those factors, the energy consumption especially have to be considered and reduced as much as possible.

Marc:

Cool. Perfect. Thank you so much. So second question would be quite easy hopefully. How can cooperation between research, factories, and suppliers be expanded to accelerate progress in the battery industry?

Christian:

Great question. I think the innovation chain is one of the major topics that we have to address in Europe in the future. Since if you’re not addressing that topic, you can’t differentiate yourself from other suppliers and in that case you have to do fundamental research with governmental help. You have to do the scalability afterwards.

You have to transform that knowledge, that innovation to an industry. For that case there are different game changers in my mind. First I think you have to use pilot lines, you have to use lines that can scale up like UK Battery Investigation Center or the Fraunhofer research factory where you can improve the innovation to a scaled production line. Then you have to transfer that to the industry. In that case, I think there has to be a close cooperation between research universities and the industry. You have to do that with bilateral projects. You have to do research projects together and there are different clusters that are addressing exactly that topic. Cluster Ghost industries for example, one example for that. I believe that the cooperation has to be improved in the future, but still there are a lot of things that are happening in that field.

Marc:

Perfect. Christian, thanks for the spontaneous answers. That’s really great that you have the time for us and keep having a battery show in your mind and to accelerate successful battery show and hope to see you soon again.

Christian:

Thank you so much. You too. Bye bye.

Marc:

Thank you.

Nick:

Our last guest from Battery Show Europe is Dr. Hannes Schmueser, of Dürr Systems

Marc:

Hello, Dr. Schmueser. I just would like to have two questions to you maybe in a short time, and the first one would be, what innovation do you see will have major impact to the battery industry and what is Dürr executing on that?

Hannes:

Yeah, innovation plays a very important role for us because it’s not enough just to catch up to existing competitors, but really to innovate in terms of finding the right customer benefits and use piece for the industry.

Let me give you some examples. We work, in the field of electrode production, we work on laser drying, for example, to develop and launch a very innovative process to dry the web line and the electrode with lasers. That has the potential to shorten the dry zones, to reduce the amount of energy consumption and to increase, also, web speed means the output of the entire system. So laser drying is one of the aspects that plays a very important role to generate and come to very innovative processes to save money, to increase the quality, to save energy.

Another aspect of innovation is, for example, the field of closed loop controls. So we come up with camera systems and a so-called coating fingerprint to check the coating quality at any point of the web line. Means we can detect failures, we generate all the data based on camera system and sensors, put an artificial intelligence system on top of it in order to detect and identify the right failure, to work with the right, or you could also say smart data in order to come to closed loop controls to optimize the entire processes. Because we work with very valuable raw materials in this case here, and so these are things that have the potential to really innovate and save a lot of money for our customers and improve the quality.

Then on top of all the machines, we innovate in the field of digitalization. So think about the MES systems or MOM systems now, all the software that uses all the data that comes out of all the different machines in the process to find the right problems, to detect the right failures and to reduce scrap rates for example, because scrap rate is a very sensitive thing in the field of battery production. Customers talk about a 30% scrap rate.

So these are things innovation really pays off.

Marc:

You mentioned already raw material, so how important is the sustainability aspect in the field of battery production and have you already solutions for that?

Hannes:

Yeah, the aspect of sustainability is extremely important because raw materials are extremely expensive. So just imagine 70% to 80% of the battery cost are determined by raw materials. So to save raw materials, to save energy is extremely important, not only in terms of cost, but also in terms of all the environmental issues around the batteries.

So energy reduction and also efficient drying technologies, as said before, when it comes to laser drying, play a very important role to produce more with less energy. So that is a way in a sustainable battery production future.

And another aspect are, for example, the solvents. Think about wet coating. We have a lot of solvents in the slurry, so we have to get rid of them due to a lot of emission regulation standards we find here in Europe. And it’s good we find the emission regulation standards here in Europe because at the end of the day, it’s our environment, the air quality, et cetera. So we deliver systems, solvent recovery systems to reduce the amount of solvents in the air or in the emission stream to a level close to zero, down to zero.

So these are things that play a very important aspect in terms of sustainable processes.

Marc:

Perfect. Dr. Schmueser, thank you so much for the short interview.

Hannes:

Yeah, thank you.

Marc:

And wish you still a successful battery show here and thanks to having you on the panel discussion. That’s all.

Hannes:

Thank you very much.

Marc:

Thank you.

Hannes:

Same for you. Thanks.

Nick:

And thank you to the audience. We hope these discussions are valuable to you as we continue this style of recording when our experts meet with industry leaders and customers from around the world.

Be sure to check out our other episodes and we look forward to having you back again soon to talk about everything battery.