Designing in detail for a sustainable product

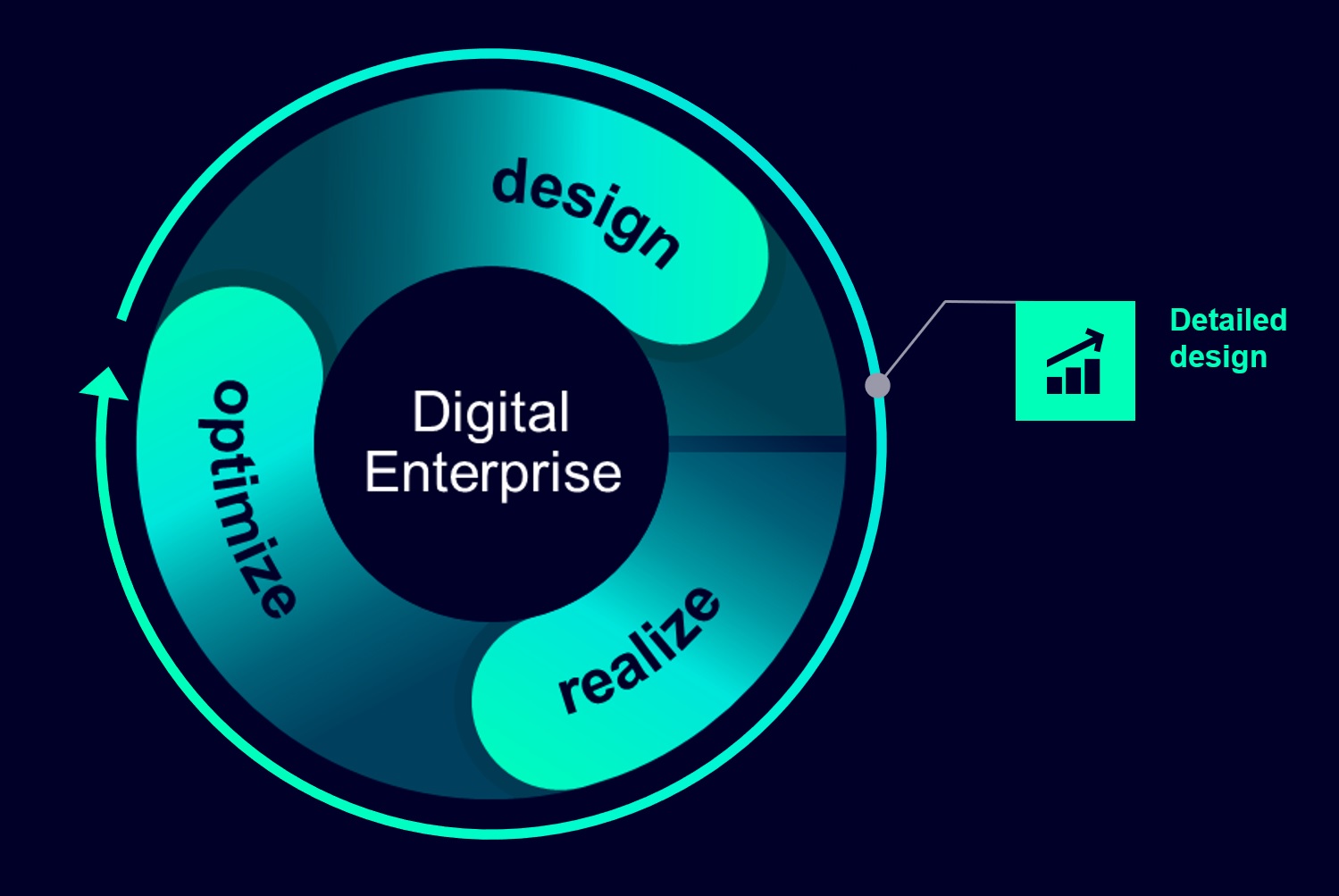

While the realm of design is only part of a product’s journey from concept to fruition, it touches every part of development. So much so, roughly 80 percent of a product’s overall carbon impact is determined during design. This is why it is so important to have the right information and technologies to make design as streamlined as possible. Over the last two part of this blog series, I’ve covered how a business defines a sustainable product’s success with conceptual design and how to go about creating the right supplier network meet those goals.

The next step is to delve into detailed design for sustainability, which means bringing together the requirements of product performance, manufacturability, energy efficiency, carbon emissions, profit, and much more for designers. Competing needs is not a foreign concept to any designer or engineer, the traditional business drivers of cost, quality, and time have been maximized against each other for many years. The challenge comes from the fact that balancing these requirements for the best design was already a challenge and now sustainability needs to be added to the equation – and sustainability comes with many of its own internal goals to balance.

But what does this look like for a designer? One simple example is how a designer might go about material selection for their product – a material like aluminum can provide better recyclability at the end of life while a lighter material like magnesium would provide a weight reduction. I’ve framed this as a simple decision, but in the real world there are many more variables that businesses will consider when designing a sustainable product. The cost of these materials is wildly different, the manufacturability of magnesium over aluminum could require specific suppliers, and the emissions associated with either material could change the final decision.

This is where digitalization shows it’s importance within detailed design for sustainable products. Testing each of the different combinations of material choices and geometric decisions manually would take far too much time and too many resources for a designer to come to the best balance. Instead, by leveraging simulation models and comprehensive material data within the digital twin a designer can spend their time perfecting the product rather than tracking down value and performance metrics.

Design requirements, for sustainability or any other, also determine the best manufacturing processes for a product. Extremely complex parts may benefit from additive manufacturing processes while other geometries may be better suited to machining the part from a common feedstock. Finding the right balance for manufacturing starts in the detailed design phase as well. A previous simulation may provide a designer with a topology optimized part, but it should be examined alongside the manufacturability, material, and energy requirements to bring it into the real world. That might mean simplifying the part to be more readily manufactured with mass production techniques or sending the design off to a 3D printing partner to check the printability of the design.

No matter what a designer is working on during detailed design, it is important that the changes get collected and analyzed continuously in the digital twin to ensure KPIs are met and that the final product meets the intended application. A digital native design process enables that rigor through connected simulation data, material information from suppliers, and manufacturing capabilities of your suppliers.

For more information about developing products sustainably, check out our website. And to learn more about the earlier stages of the design process continue reading with conceptual design practices or integrating suppliers into your design process.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.

For more information on Siemens Digital Industries Software products and services, follow us on LinkedIn, Twitter, Facebook and Instagram.