How machine learning plays a vital role in IC verification

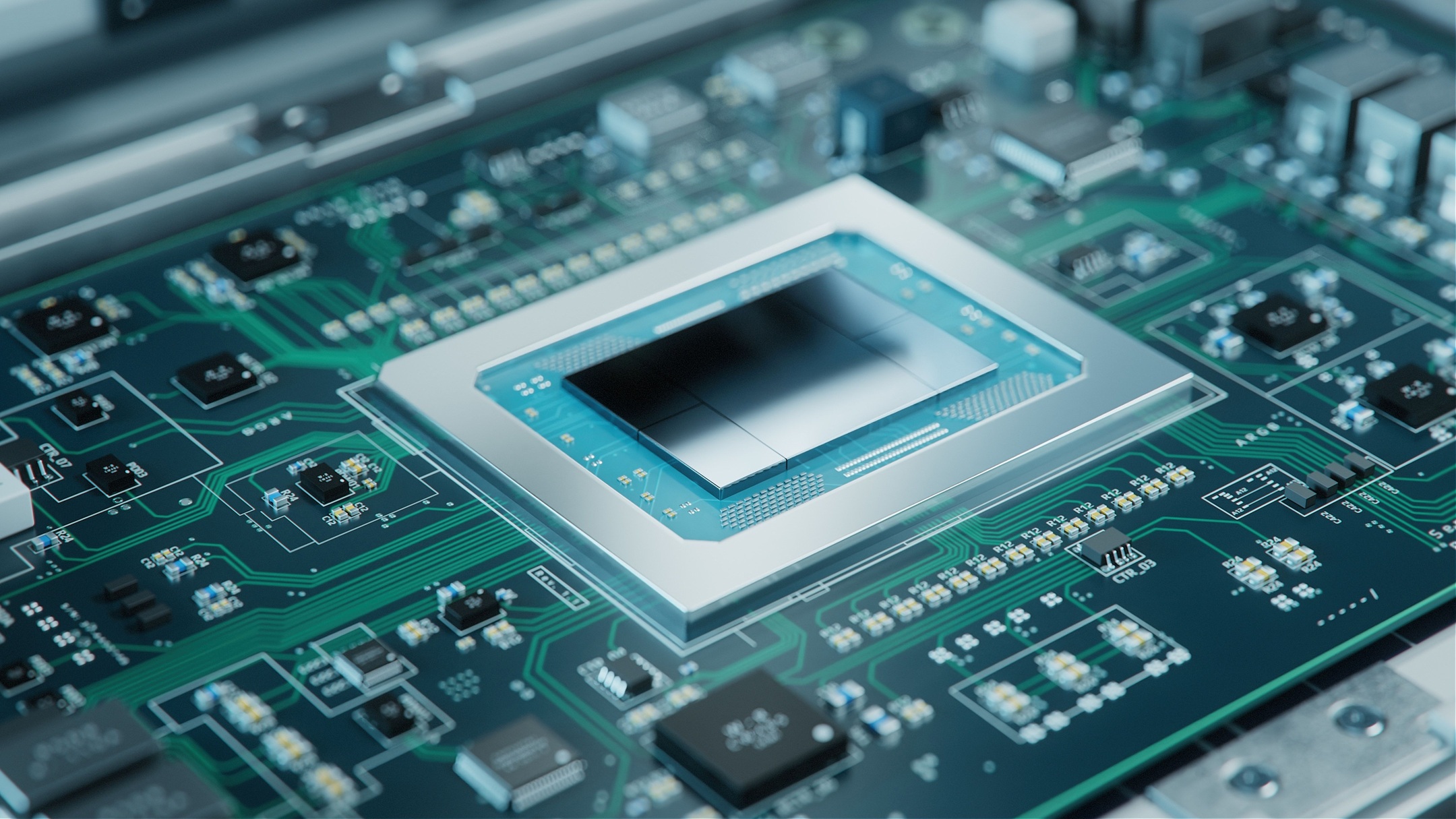

Microchips are among the most complex devices ever created by humans, with billions upon billions of transistors crammed into a space the size of a fingernail. As with all man-made products, it’s only natural for some defects to arise during the manufacturing process, however, when it comes to checking billions of transistors just a few dozen atoms wide the error detection process becomes far more difficult. In a recent podcast, I spoke with an expert from Siemens EDA’s Tessent on how they are using machine learning (ML) to identify and understand the root cause of failures within microchips – without having to check every transistor.

Every microchip that leaves a semiconductor foundry must work perfectly, down to the smallest transistor but checking every single feature on a single chip would be impossible, much less doing it for every one of the millions of chips coming out off foundries every month. As chips have grown smaller, denser, and more complex, the testing apparatus used to validate them has had to grow with it. Rather than testing each transistor individually, a series of test signals are sent through the chip to ensure it can correctly execute all the basic functions it should be capable of – a process that can be completed in seconds. If the chip passes all these tests, it can be shipped and packaged but if it does not, that’s when further analysis is required.

Because the testing apparatus looks at results, rather than individual features, that means a single bad result can originate from anywhere in a long chain of logic processes that modify a signal from its input into the chip and what is produced as an output signal. Examining where in the chip these bad signals originate from is called logic diagnosis, a key element in improving yields. Since multiple different faults can result in the same bad answer matching results to problems is a difficult task, which is where machine learning comes into play.

The process of identifying the root cause of failures is analogous to trying to find, by sound, the locations of a half dozen lumberjacks in a forest of a billion trees. The sound of each lumberjack quickly overlaps with all the others, making it nearly impossible for an observer to pinpoint the location of one by sound alone.

By using a machine learning model trained for a particular chip, it’s possible to cut through the noise in the resulting data and match different data points to particular failure modes, be it manufacturing defects or problems with the process itself. To extend the above metaphor, the ML algorithms can deconstruct the combined sound of all the lumberjacks chopping and “listen” to only one at a time, making it possible to locate each one in the massive and noisy forest without having to cut down every tree first.

While this may seem like a mundane process, it is still a highly important one. As microchips grow denser and more complex not only does it become harder to validate that all the internal logic is working correctly, the cost to manufacture them goes up as well. As the cost of wafers continues to rise, so too does the cost of each defective chip that must be thrown away. Using tools like Tessent to find and analyze defects can help designers find ways to optimize process equipment and quickly zero in and correct minor design errors by highlighting patterns found in the test data.

Creating increasingly advanced chips will require tools to not only become better and more advanced, but smarter too. To continue pushing the boundary of what is possible, artificial intelligence and machine learning are being integrated into every level of the chip design process from concept all the way to validation of the finished product. Going forward, AI and ML will play an increasingly large role in the continued development of advanced microchips and, in tandem with designers, advance further than either would be able to alone, driving not only smarter and more sustainable technology but creating a platform for more powerful AI as well.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.