Sustainability in smart manufacturing is making a major impact

Sustainability is a buzzword in almost every industry, becoming an important global topic. We have spoken with experts in their industries, getting their take on the impacts of sustainability and how things are changing.

We recently had the privilege of speaking with Rahul Garg, VP of the Industrial Machinery Mid-Market Program at Siemens Digital Industries Software and Chris Pennington, Global Industry Marketing Leader for Industrial Machinery at Siemens.

We are learning that sustainability considers the impact that our industry has on the world we live in and how it can minimize adverse effects, followed by taking actions to contribute to the business and improve the industry’s influence on the environment.

One-third of the energy produced today is consumed by the industrial sector, with the majority being in manufacturing, creating the potential for a significant impact. Sustainability in manufacturing involves several factors.

First, energy usage concerns the energy used to run the production process and its resulting carbon production, which inherently has negative environmental results. In response, circularity and recycling are a conscious effort to ensure manufacturing outputs are reusable instead of polluting landfills in oceans. This includes product recycling and the machinery used to produce it.

Sustainability in the manufacturing business has the perception of a negative, unaffordable impact when it can actually have a significant positive impact on the industry. So, if done correctly, it can include increasing energy efficiency, resulting in lower energy cost and reducing carbon production, which benefits the company and the environment to impact the bottom line.

Also, recycling raw materials, like metal scrap wood pallets, have value in the marketplace, and improves company financials, reducing negative environmental results. For example, even a five percent reduction in the electrical power requirements of a motor running in a factory can significantly impact the environment.

One of the most significant reasons sustainability is increasing its focus on machine design and energy efficiency is machine optimization for energy usage. Additionally, the supply chain elements relative to energy consumption and recyclability ensure that machine parts can be recycled and not discarded for the end of the machine’s life.

Also, as financial markets, customers, employees, and communities become more aware of sustainable industrial practices, there are obligations to ensure that a company communicates those capabilities and their focus to the rest of the world.

Lastly, workflows, productivity, supply chain, carbon neutrality, traceability in your supply chain, and a circular economy track the identifying recyclable and remanufactured parts which makes it easier to close the loop and ensure what and when a design gets used. Subsequently, it recirculates back into the design, engineering, or development process at the end of life.

An industrial machinery company is twofold: operating itself, and managing sustainability while desiring the operating systems and working practices to be more energy efficient. And, don’t forget that the customers want their machines to be more energy efficient. Therefore, they want to lower operating costs and make them more sustainable as well.

All of this significantly impacts producing and selling of more energy-efficient machines, creating an important point of differentiation and providing the machine builders a competitive advantage in the marketplace.

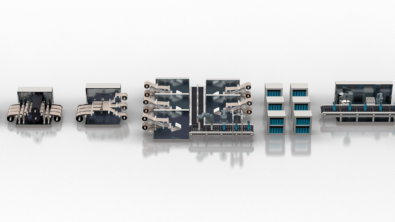

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries, Siemens Digital Industries Software is where today meets tomorrow