Smart manufacturing provides efficiency with OT/IT convergence to uncover actionable insights

In a recent Machine Design article, Rahul Garg, VP of the industrial machinery industry at Siemens Digital Industries Software, explains how smart manufacturing enables industrial companies to address many challenges: sustainability, supply chain, labor shortages, and competition.

Factories desire maximum efficiency to drive optimum utilization. Digitalization is an equalizer to achieving innovative levels of smart manufacturing. Previously, the focus of automation was reducing costs. Digitalization helps manufacturing processes move to a new level in the current environment.

OT and IT convergence achieve more significant operational efficiency to uncover actionable insights. This provides rich data generated by factory operations technology (OT) using edge sensors and smart equipment. Then information technology (IT) can store, retrieve, process, analyze and recommend actions founded on that data.

In turn, the actionable data advances to a closed-loop manufacturing process that continually optimizes with closed-loop product quality. This process supports the comprehensive digital twin creation of the manufacturing environment to maximize throughput.

IT/OT convergence is an essential step in smart manufacturing. So let’s begin by defining both:

- Operation technology (OT) – Provides the capabilities that run a factory. It includes all the software that goes into the operation of the physical equipment, the controls and the technology driving the machines, and the programmable logic controllers (PLCs). In other words, it helps the factory to function.

- Information technology (IT) – The organization’s computer information technology stores, processes, analyzes, and acts on data gathered from operations. Supervisors and management use IT to make decisions, while operation technology drives actions.

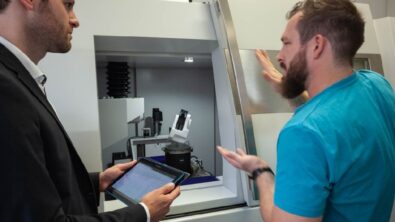

Innovative smart machines share data with a network, while older machines are in silos. A smart factory has a network of sensors to connect these silos to ensure robust data across all manufacturing operations, combining operational data for IT to analyze. Edge sensors stream data to various measurements, providing knowledge of the equipment’s performance. Currently, in most factories, data is collected by physical sensing technologies (PLCs, sensors, gauges, IoT devices, etc.)

OT and IT interact more to achieve optimum operational efficiencies. Conventionally, these were two distinct areas. However, the desire for greater operational productivity blurs the lines between traditional information management to provide essential data that improve overall operations.

So, the convergence of OT and IT happens when information technology is captured while the factory floor is running, fed into IT systems that optimize business decisions digitally, viewing this data from edge sensors in smart machines. Understanding how the equipment runs makes it easier to initiate real-time choices, thus, optimizing and further maximizing factory throughput.

Learn more about smart manufacturing, closed-loop manufacturing, and the digital twin to attain better quality digitally, making a business run more efficiently.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries, Siemens Digital Industries Software is where today meets tomorrow.

Rahul Garg is the vice president for Industrial Machinery & SMB Programs at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. More information on Siemens Xcelerator, a comprehensive and integrated portfolio of software and services that can help companies realize digital twins, can be found here.