The digital twin and what it can do for you

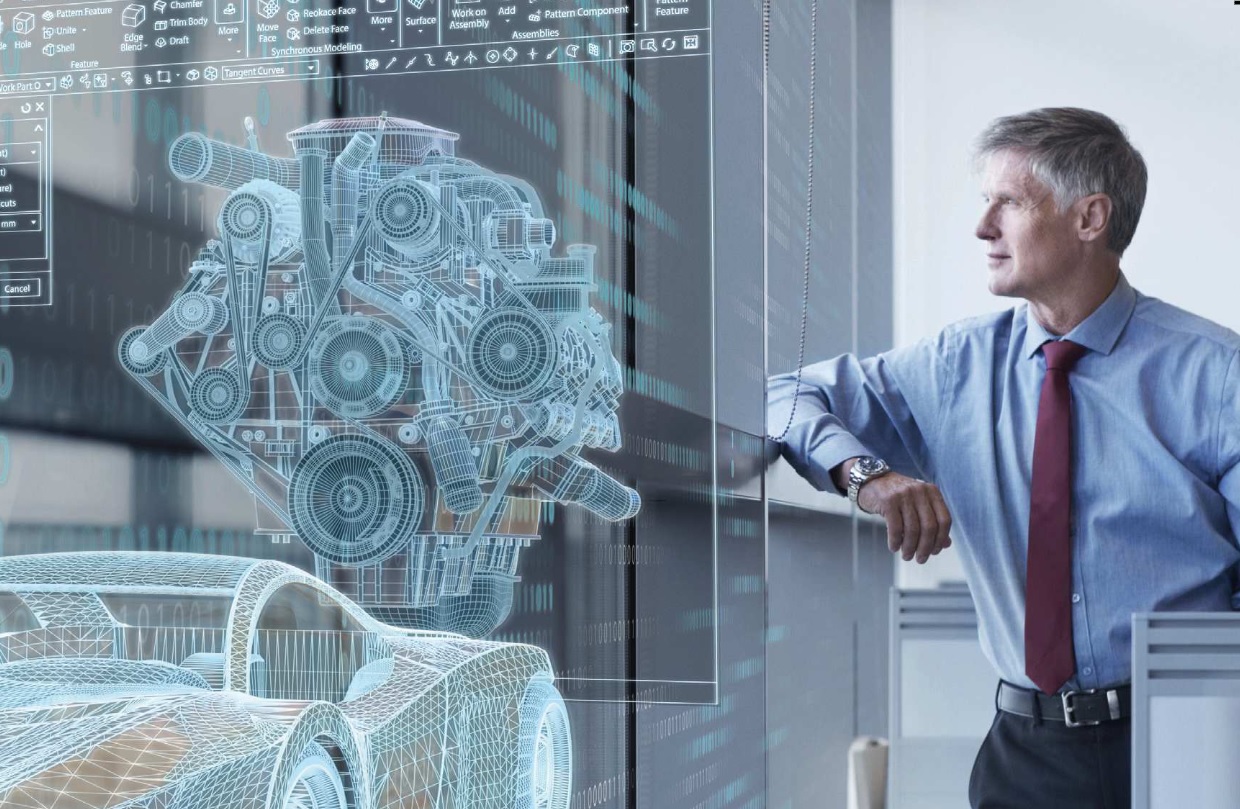

You have likely heard or read the term ‘digital twin’ in podcasts, blogs, or articles. The term has proliferated lately in technology and industrial discourse, with various companies touting the benefits of their ‘digital twin’ offering. Each of these versions of the digital twin is generally based around a core concept: the digital twin as a virtual representation of a physical object or product. This virtual representation may include design, simulation, or other models that evolve and change over time as the product it represents matures. In other words, the digital twin merges the virtual and real world, blurring the boundaries between engineering and process domains.

Yet, outside of this core concept, what the digital twin is and what it can do quickly diverges depending on who you ask. Is it a data or a process flow? Is it only a highly accurate representation of a product in its current state, or should it also predict product performance or other attributes? Is it limited to the product, or should it extend further across the lifecycle or value chain? Can a product have multiple digital twins, or should it be represented by a single twin?

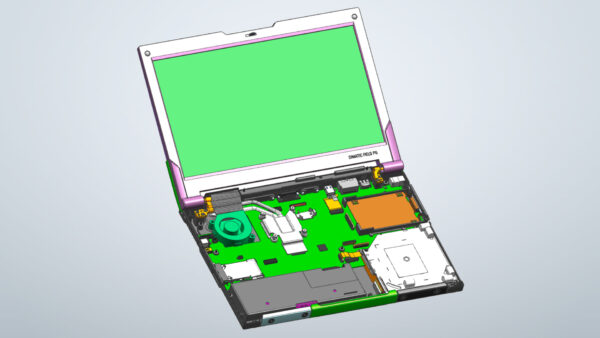

With only one, the digital twin of a product must include and support the numerous lifecycle phases and respective models of actual product behavior. This comprehensive digital twin has the following characteristics:

- Offers a precise virtual representation of the product or process flow that matches the exact physical form, functions and behavior of the product and its configurations.

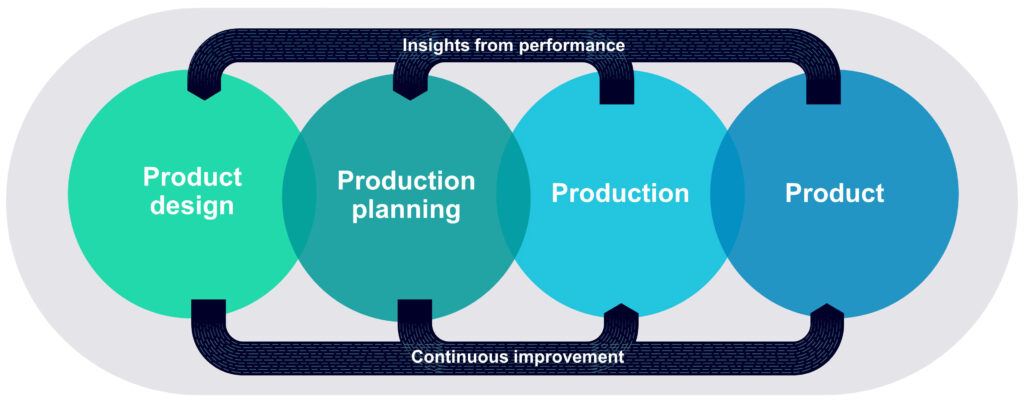

- Participates across the product and process lifecycle to simulate, predict, and optimize the product and production system used to create the product.

- Connects real-world operational data back into product design and production over the lifetime of the product to continuously improve quality, efficiency, and quickly respond to customer demands or market conditions.

A comprehensive digital twin of the complex and increasingly intelligent products of today will encompass all cross-domain models and data, from mechanical CAD and CAE to software code, bills-of-materials, bills-of-process, and more. And, as mentioned above, this digital twin continues to evolve and mature along with the product as functions are refined, simulations are completed, test results gathered, and design changes are implemented. The comprehensive digital twin also extends beyond the product design into production and the product in the field. With connections to the IoT and cloud-based data analytics, the comprehensive digital twin can operate as part of a closed-loop feedback mechanism between the product design, the production system, and the product in the field. This creates an integrated system to validate, compare, and optimize behavior between the physical assets and the comprehensive digital twin.

As this integrated feedback loop extracts terabytes of data from the connected product and manufacturing lifecycles, the comprehensive digital twin helps to organize and extract value from this data. Not only does this deliver benefits in the short term, but this data also offers ongoing advantages as re-use can help to accelerate design assessments and tradeoff analyses, leading to faster decisions. Moreover, the comprehensive digital twin enables your company to design, build and optimize next-generation products faster and cheaper than ever, with fewer prototypes, fewer tests and less waste during production. The result is a distinct competitive advantage in meeting growing customer demands for greater performance, smarter features, higher-quality and personalized experiences.