Smart manufacturing optimizes machining

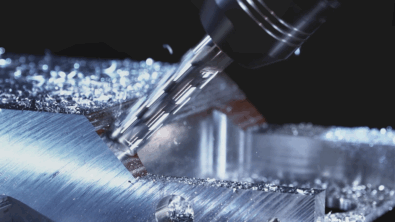

Smart manufacturing assists in optimizing manufacturing machining that includes machine creation, execution, manufacturing and service life.

Subsequently, smart manufacturing creates a growth path for entering a dynamic marketplace. Moreover, this innovation provides many benefits like improving manufacturing throughput, uptime, and performance while minimizing costs.

Providing machine capabilities and manufacturing digitalization

Smart manufacturing permits machine manufacturers and designers to create value by closing the loop between manufacturing operations and engineering to generate growth in this technology. Machines use various design proficiencies to supplement smart manufacturing, including connectability, adaptability, predictability, and extendability.

Smart manufacturing provides intelligence to each manufacturing process area to include the Internet of Things (IoT), Industrial Internet of Things (IIoT), and Industry 4.0. So, it combines intelligence with machines, parts, materials, products, building and supply chain. It also supplies intelligence to a connected, open end-to-end process and infrastructure. Therefore, the focus is on data and not the system.

Maximizing smart manufacturing with digital twin, robotics and bill of materials

The digital twin is essential to smart manufacturing, providing a holistic tactic to machine simulation, incorporating the mechanical, electrical and programmable logic control (PLC). The result is the product’s digital twin linking with the machine’s digital twin.

So, the part process includes building, executing, managing delivery, manufacturing, operations and quality. Subsequently, manufacturing operations drives utmost efficiency by harmonizing the correct parts at the right time.

Recent technological advancements in part manufacturing require CAM software to exploit production capacity. Therefore, robotics is a mainstay in the contemporary machining environment, using human-assist robots (cobots). Therefore, integrating advanced robotics is vital to smart manufacturing solutions to simulate robot performance and integrate it on the factory floor.

Additionally, with overt machine complexity, a bill-of-materials (BOM) requires smart manufacturing. The BOM provides:

- practical displays,

- traces the individual source of truth, and

- extends from the engineering bill of material to the manufacturing bill of material.

These many capabilities assist companies in adopting innovative processes to improve the machine’s overall performance, thus refining products, processes, resolving failures and improving machinery operations.

Software innovations

Lastly, all these technological innovations in the machinery industry are prompting companies to be aware of the critical implications of Industry 4.0, resulting in trends such as consumer-driven customization, smart machines, hyper-automation, and highly innovative competition globally. These trends improve machine performance to refine products and processes, resolve failures, and improve machine operation. *

By using the Xcelerator portfolio, via Siemens Digital Industries Software suite of products, it assists to simulate testing virtually, saving time and money in modeling, and optimizing operations before construction or equipment installation begins. The digital twin for smart manufacturing saves time and money for the machine manufacturer, the product manufacturer, and the end customer. They now know what needs to be built, thus providing exceptional value for all parties. Smart manufacturing with a comprehensive digital twin is where today meets tomorrow.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – where today meets tomorrow.

Related links and sources:

*Getting smart– Manufacturing Automation article

Accelerating value realization in the smart factory – eBook

Smart manufacturing takes center stage in 2022 – sme.org article by Rahul Garg of Siemens

Smart machines, smart engineering (blog)