A new vision for the future of aerospace

Possibly the greatest challenge to development with a document-centric process is that these files need to be placed somewhere. Even traditional model-based systems engineering (MBSE) processes revolve around documents, whether physical or digital. But with the most rigorous file management, mistakes can be made. Paper documents end up in file cabinets in different offices or under stacks of other documents on a desk. Digital documents do not fair much better stored on employee laptops, shared drives, or cloud services. If a document is found, version history may not be present allowing work to proceed from an outdated design. Next generation MBSE solutions retain all of the data that would be held in disparate documents in a single model, visible and accessible to those in need. But this centralization also enables teams to work cohesively rather than in silos until an integration step later in development.

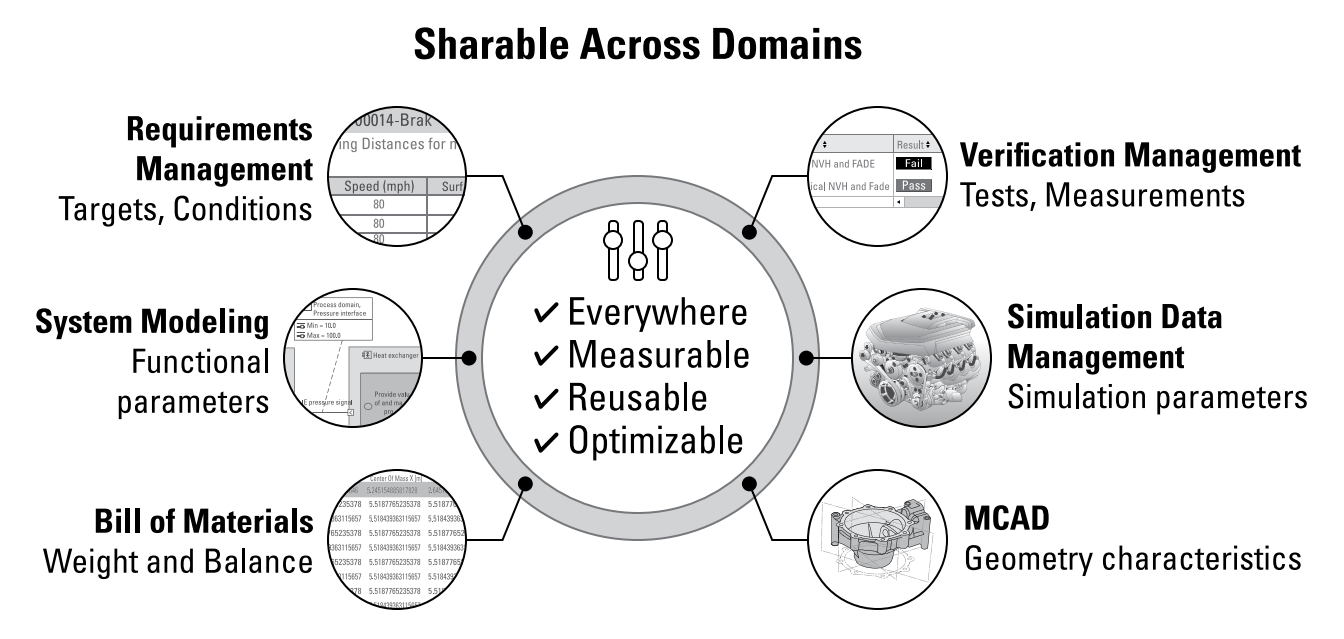

Orchestrating a technical program with MBSE changes how everyone interacts across the project, rolling functionality down from early concept design through deployment and everything in between. MBSE is meant to keep all of these groups in sync, even in an unpredictable environment like aerospace development. Changes made in one domain need to be visible immediately across the organization to ensure they do not negatively impact another system or group of systems. This extends to the large supplier networks of aerospace programs as well such that the right subsystems are delivered and can be integrated properly into the larger system of systems. Creating this interconnection across such a breadth of tools and disciplines requires the sharable parameters outlined at the start of an MBSE program, with examples below.

While sharing every piece of data created and consumed within development can be highly valuable, it can be burdensome to constantly receive information irrelevant to your workflow. This is where some intelligence is needed in the process because while everyone needs to feed the model and work from it not everyone needs the same information. A background data structure organizes the comprehensive information of development, from the many different tools in use. The model needs to be interrogatable and refinable for every part of development. A mechanical engineering team may not need to know the function of every wire in a harness bundle, but they would need to understand the dimensions of it and some requirements around its placement in the system. Perhaps a cutout in a vehicle frame needs to fit not just the wire harness, but the connector on the end. But for newer additions to the business, more information may be required to get a supplier up to speed on the development process and identifying how to integrate their work into the greater system.

But these improvements to development are only improvements if they have a calculable benefit. Is the project getting done faster? More efficiently? At a lower cost? All of these are possible with a modern MBSE methodology, and in aerospace even a single improvement can have massive ramifications due to the tight schedules, design space, and budgets. Companies can reduce their development cycle by 25 to 30 percent, while also reducing risks associated with late-stage error findings. The combined data of the entire project enables multidisciplinary studies earlier in development to shed light on performance limitations. An later in development the digital and physical worlds can intermingle more effectively through simulation and actual testing to minimize total tests needed to validate a system. MBSE provides the scalability that will be required for the complex aircraft of today and tomorrow, especially during the energy transition towards electric propulsion or new fuel systems.

Model-based systems engineering may be the past of aerospace development but eschewing the dependency on document-centric tools for a purely model-based and digital solution is the future. The approach brings together once siloed domains in development, it provides relevant information to all stakeholders, and it provides a substantive benefit with adoption, from concept design through deployment. If you are interested in learning more about the adoption of MBSE for the aerospace industry, the Siemens Special Edition MBSE for dummies is an informative place to start researching the solution.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow