Simulating the unexpected

There are many applications of AI and machine learning out in the world that improve processes. Some applications provide faster answers to questions based on a massive set of data. But my preferred applications are the ones that come up with a solution that a human never thought about.

One of my favorite technologies to study is the autonomous vehicle, because it is an impressive blend of electronic and mechanical engineering with a significant level of AI content. It is a great platform for exercising AI-driven ideas. In the world of autonomous vehicle design, AI testing is vital, because teams need to identify all the dangerous scenarios that could arise in the field. Unfortunately, there are edge cases that no team can think of ahead of time.

Design teams are looking for fast ways to find these edge cases because they put stress on the autonomous vehicle development schedule. For example, one scenario could be that the car is driving through rain and fog and suddenly two pedestrians jump in front of the car from different locations. The car needs to react by using a combination of steering and breaking. But how can teams find and simulate all these unexpected scenarios? Instead of running billions of simulations, they apply machine learning. In a machine learning environment, a technique like adaptive sampling allows teams to learn from the problem, understand the physics, appreciate the context, see where the dangerous situations are and hunt for these very particular cases. The environment should present a map of where these edge cases are. Adaptive sampling presents a model of the knowledge and a model of the information about a dangerous condition is generated automatically. So, the team does not need to go hunting for this scenario, they save a lot of simulations and get an accurate representation of where the problem is. In addition, it would be nice that this system had these qualities:

- Must support all members of the product development without being experts in AI, machine learning, statistics and optimization.

- Needs to easily interface with tools in the design flow and support a wide variety of input formats.

- Must provide insight and discoveries of designs that are production-ready.

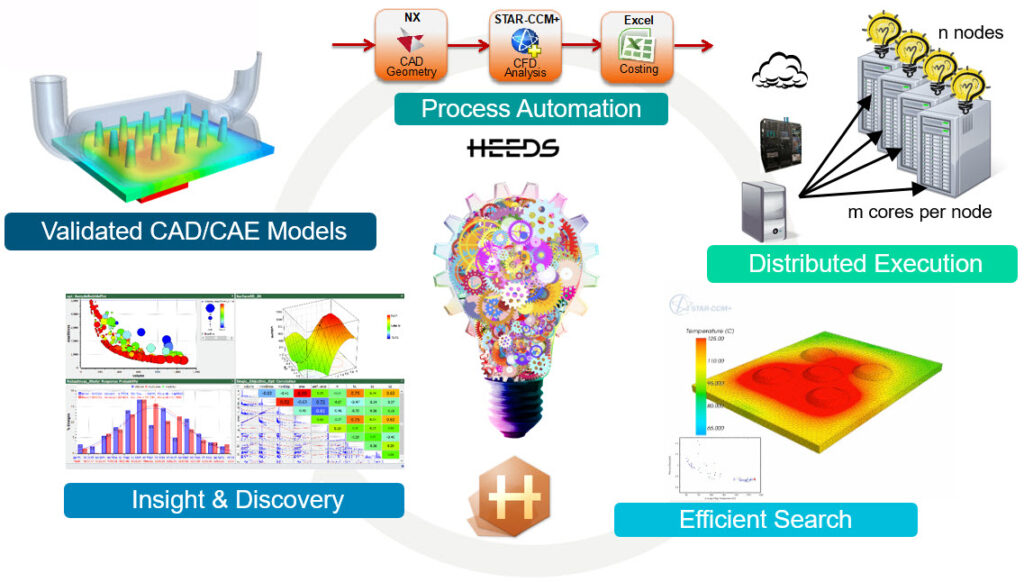

Sounds like a dream environment. But it exists. Siemens offers HEEDS, which is a multi-disciplinary design analysis and optimization software package that leverages design space exploration to accelerate product development and reduce overall cost. Teams use HEEDS to find innovative solutions that satisfy all performance requirements – faster.

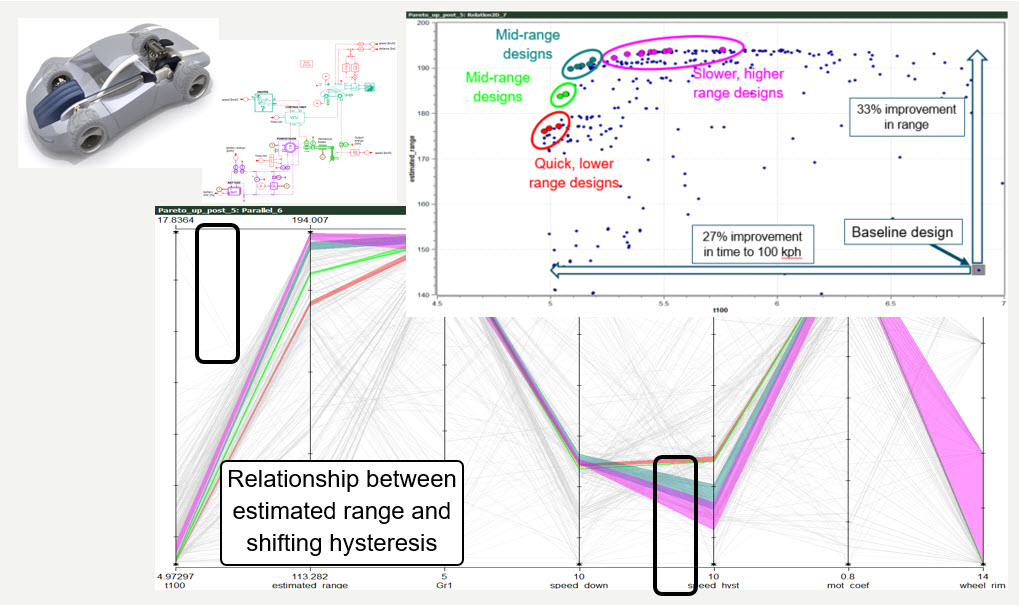

Companies designing any vehicle can employ HEEDS within their design flow. Aside from our example, they have used the solution to tackle component design issues like minimizing bumper mass to designing an optimal gasket. One company used the solution to minimize the full weight of a vehicle. They automatically found a feasible design that reduced the weight by 18%.

I wanted to learn more about all the solution spaces and the AI employed in HEEDS. So, I sat down with the product manager, Roberto d’Ippolito, for a chat. We focus on how HEEDS fits into the simulation equation, the key benefits of using the technology, and the process of designing automated vehicles so that unpredictable situations are accounted for. We wrap up by touching on a few misconceptions about AI, and where it might lead us in the future.

Listen to this interview here.