Transitioning to the digital enterprise? Don’t forget some nice threads.

In my last blog I talked about major disruptions in the industry and how digitalization is the key to not only facing the complexities of today, but a way to come out stronger, better, and faster on the other side.

But still, not everyone in A&D is enjoying the fruits of the digital age.

Why? To be honest it could be any number of reasons. But there are a couple of misconceptions out there that I’d like to clear up. Perhaps a better understanding of what is meant by digitalization is needed.

First, let’s talk about the differences between the digital twin and digital thread. And then we can discuss digitization vs. digitalization.

The Siemens digital twin and thread

To successfully transition to the digital enterprise you need to have both the digital twin and digital thread. Now, the digital twin has been around for decades. Essentially, the digital twin is a virtual representation of a product or process in the proper context so teams can analyze, study, and improve the product or process under development.

Companies need a digital twin to better predict product performance and production processes prior to verification or certification testing and physical production, reducing development time and costs. This minimizes their risks and ultimately leads to creating and winning new business as they get to market faster and manage their costs better than their competitors.

Now, here’s where it gets interesting. You can have a digital twin doing all the right things, but if it’s not connected or integrated to all phases of product lifecycle development, then you’re not realizing the twin’s full potential. You can set up a digital twin for just about anything in the engineering or manufacturing disciplines. We see a lot of examples around the digital twin and 3D CAD implementations. But it’s about more than managing just the 3D CAD – you need a digital twin seamlessly connected to other digital twins, or to other phases of program development for the continuous exchange of data – the enhanced automation of data – up and down the product development lifecycle.

You need to get some threads. And this is where the digital thread comes in.

The Siemens Xcelerator not only represents the industry’s most comprehensive digital twin but brings a series of adaptable digital threads to the aerospace and defense industry. Siemens is the only company today to offer a digital twin that’s fully connected to a series of digital threads for increased automation and digitalization. With the digital thread, all processes are connected. Customers gain a deeper understanding and greater visibility into all product development phases up and down the value chain.

Digitization? No, it’s digitalization

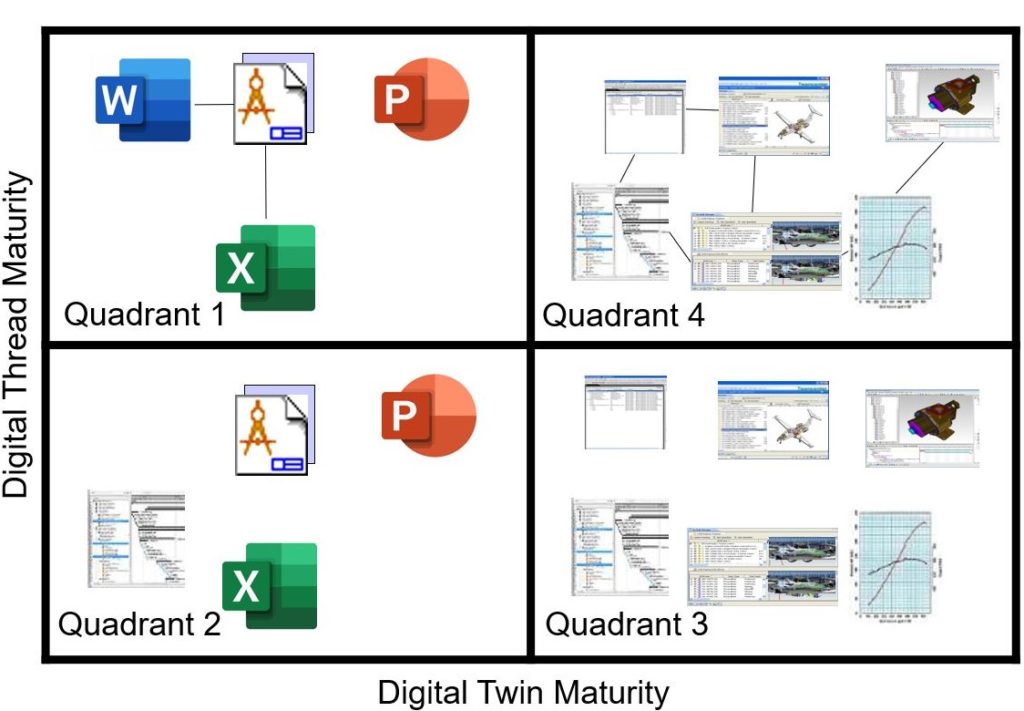

With the understanding of the digital twin and digital thread, let’s look at another issue companies are facing as they transform their operations to a digital enterprise. We can talk about this by examining the visual below.

This illustration represents the different stages a business or company goes through as it transitions to a digital enterprise. Oftentimes, a company stops short of the final stage depicted in quadrant 4 – which may be why some companies are not realizing the full benefits of their digital enterprise.

Let’s dive into each quadrant.

Quadrant 2 is where companies begin. Information is placed into a Word doc or an Excel spreadsheet. Simulation or modeling programs are started, but nothing is linked. When a user moves something from paper to a software-based program, they are “digitizing” that artifact. This is primarily a document-based system.

Quadrant 1 and quadrant 3 represent a middle ground where most companies are today. Data is imported and translated from an external source but nothing is fully connected. Oftentimes the information is out of date creating document maintenance and data management issues. Further, one team is managing engineering data in one system and another team manages the production data on an entirely different system. Program management, scheduling and tracking are also on different systems. When information is needed, data is pulled together manually or by a home-grown method.

More on quadrant 3. This is where a lot of folks think they’ve achieved digitalization. The digital twin is in place and functioning at full maturity utilizing 3D CAD models, simulations, etc. Even with a virtual representation in place, there is no sharing across the product lifecycle or supply chain (lack of fully operational digital thread). Oftentimes, the hand-off from one phase to the next is incongruent or error-prone.

Quadrant 4 is a fully digitalized enterprise. Connections are made between virtual representations or twins with a digital thread. Seamless integration of the entire value chain has been achieved. Common tasks are automated and everything’s networked together. Requirements drive the entire design, manufacturing, testing and service systems. When there are updates they are automatically shared up and down the value chain. It is here where the digital thread connects all processes to provide integration throughout the entire lifecycle of product development. This is also where a fully mature digital twin and a fully operative digital thread come together.

Achieving A&D program execution excellence

The bottom line for any A&D customer is improving program performance – whether it’s faster time to market, cutting costs, or adding the latest capabilities. It’s about unlocking innovation so you can go faster. It’s about adding productivity enhancements through digitalization. And today more than ever, it’s providing the tools for increased collaboration among remote teams and empowering individuals working off-site.

When it comes to digitalization Siemens provide seven A&D digital threads that take advantage of our Xcelerator portfolio, and when combined with our deep industry knowledge, provide a key competitive advantage for our customers.

Our seven A&D digital threads:

Model Based Systems Engineering (MBSE)

The MBSE digital thread provides the platform for faster and more efficient product development, even in these times of increased complexity. The MBSE thread connects to all of the other threads, and orchestrates your technical program and helps you manage program scope. By facilitating early analyses and simulations tied to requirements and functions, this digital thread reduces the consequences and impacts of “issues” that have historically appeared at the last minute during system integration and evaluation.

Integrated Program Planning and Execution

This digital thread provides a systems-based approach to project planning. It utilizes a single interface to integrate cost, schedule, risk and technical requirements into a fully planned, resourced and budgeted program management solution. You get one common solution and an integrated view across all domains of your pursuit or program.

Product Design and Engineering

Provides a comprehensive design and engineering environment with integrated CAD/CAE that maximizes reuse and provides advanced configuration management. Utilizing requirements and simulation-driven design, you are able to quickly develop optimized multi-domain solutions, increasing product performance and getting the design right the first time.

Verification Management

Customers achieve rapid certification through the synchronizing of requirements from design, analysis and test of either virtual or physical assets. With this solution, you can trace all verification artifacts from physical or virtual testing back to requirements-based verification plans to reduce your program risk during certification.

Supplier Collaboration and Management

Enables complete traceability from OEM requirements to suppliers and allows for proactive supplier management. With powerful data rights management, the solution enhances collaboration throughout the value chain.

Intelligent Manufacturing

Provides a comprehensive digital twin of manufacturing and utilizes a digital thread to provide seamless integration from engineering to production and brings relevant production data to every aspect of program development. Through virtual manufacturing and commissioning, teams “fly it before they build it” and shift the manufacturing development process left.

Product Support and Management

Enables manufacturers, owners and service organizations to support complex products with a service management environment. Provides service-oriented physical product definitions and maintenance information for the accurate and rapid performance of critical service functions.

These seven digital threads are just the latest example of how Siemens is helping the industry achieve program execution excellence as more companies transition to the digital enterprise.

New!

Siemens A&D Podcast Series “Talking Aerospace Today”

In my podcast series, I delve into greater detail on how Siemens Digital Industries Software is transforming the A&D industry.

Podcast #1

In my first episode “An Integrated Approach: Program Planning and Integration” I touch on the importance and advantages of a well-executed program across the entire product lifecycle.

Podcast #2

In my second episode “The Future of Aerospace” see how a more digitalized approach is quickly becoming the norm for the industry today. An all-electric aircraft from Bye Aerospace among many other topics are covered.

Check out our new on-demand webinar

In this webinar “Integrated Program Planning and Execution for Aerospace and Defense” we’ll go into greater detail on what successful program management entails during these challenging times of increased complexity. What is the role of the digital thread during the competitive bid process? How does the digital thread integrate cost, schedule, risk and requirements into a fully thought-out solution? Join me and discover how digitalization is changing program planning and execution throughout the A&D industry.

We’re leading the way…

tomorrow’s technology here today

With our comprehensive digital twin and digital thread technologies, we are helping customers across the A&D industry meet their rapidly changing needs. By providing flexible and adaptable applications in a modern and open ecosystem known as Xcelerator, we are bringing the future promises of tomorrow to the desktops of our customers today.

Visit our Siemens A&D website for more details.

(This is blog #2 in my 3-part blog series “Program Excellence in the Digital Age.” The underlying theme of this series is how, during this time of intense innovation and digital disruption, you can turn digitalization into your friend and ally.)

About the author: Dale Tutt is the Vice President of Aerospace and Defense Industry, for Siemens PLM Software. He is responsible for defining the overall Aerospace and Defense industry strategy for Siemens PLM, driving specific industry requirements into software products and solutions, and working with the Marketing team to define industry-specific market solutions for Aerospace and Defense customers. Dale has 30 years of experience in engineering design, development, and program leadership within the Aerospace industry.

Comments