Manufacturers: get ready for the algorithms

The latest biological research suggests that all animal life on Earth is best described as meat-based algorithms. From the fruit fly to the killer whale, animal behavior is the result of survival logic, codified in our DNA.

That’s bad news for the humanists — we may run more complex code, but it looks like we’re just algorithms, too. For anyone ready to cry “free will,” yes, you get to decide whether to carry out that last thought that popped into your head.

But why did it pop there? Algorithms.

Psychologists since Sigmund Freud have known how to manipulate opinions and decisions by tapping into the autonomous logic that runs in our subconscious. The decision heuristics or biases that Nobel laureate Daniel Kahneman describes in his book Thinking Fast, Thinking Slow are essentially bugs in the code of our operating system that make us easily hackable by advertisers.

Since the 1950s, corporations have been catering to our encoded self-interest and selling to our unconscious desires. In his BBC documentary, The Century of the Self, Adam Curtis explained how Sigmund Freud’s nephew and public relations innovator, Edward Bernays, manipulated the sentiments of the masses. In one of his more infamous campaigns, he pushed for making smoking in public acceptable for women by calling cigarettes “torches of freedom.”

The documentary also explains how the Thatcher-Reagan era institutionalized this approach to the masses, ultimately creating a consumer society oriented around our ability to express ourselves as individuals. Computer-driven advances in manufacturing fueled the lifestyle consumer movement of the 1980s, creating short runs of products that certain groups felt were aligned to their individual philosophies. The most famous and transparent example of this was Apple’s “Crazy Ones” ad that marked Steve Jobs’ return to the company, and the subsequent explosion of iMac configurations.

The message was clear, if contradictory: you are individuals. Don’t follow the herd. Think differently. And if you buy one of these products, you show that you’re an individual.

Algorithms, artificial intelligence in manufacturing and Industry 4.0

The same kinds of ideas can be found in how manufacturers are using manufacturing artificial intelligence deciding to approach Industry 4.0.

Industry 4.0 promises exponential improvements in personalization as digitalization provides manufacturers the opportunity to dramatically increase the speed, flexibility and efficiency of their internal value chain.

• Generative design harnesses computing power to automate the ideation process, allowing designers to identify the best of thousands of potential new design iterations.

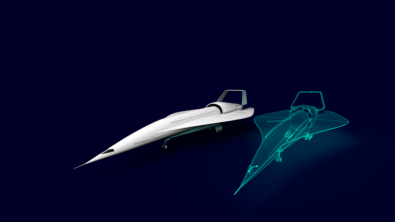

• The digital twin allows you to test products in manufacturing and in the hands of virtual end-users before you commit to building a physical product.

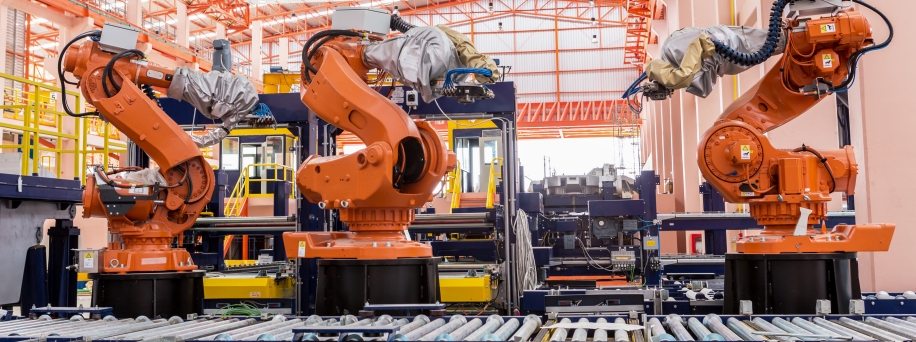

• Distributed manufacturing execution systems work with intelligent automation and robotics to make unique, correct product configurations the first time.

• Collaboration platforms create a digital thread that integrates each node in the value chain, which helps manufacturers easily answer why something is happening with their products.

• The Industrial Internet of Things combines with machine learning to compare predictions with reality and optimize the whole system.

Intelligent automation and robotics is just one of the beneficial results for manufacturers as they implement digitalization.

Intelligent automation and robotics is just one of the beneficial results for manufacturers as they implement digitalization.

However, a major pushback with this artificial intelligence in manufacturing has been that while consumers are already willing to personalize major purchases like a car, they likely won’t put the energy into customizing more mundane items that drive the bulk of the economy: groceries, cosmetics, personal care items, personal electronic devices, home furnishings, apparel and footwear.

Some would argue that we’re already making enough stuff and that we just need better algorithms to match it to consumers, similar to the approach Amazon takes with customers and delivering goods.

But the moment biologists reduced us to algorithms, the wall between computers and humans crumbled, and our status as the pinnacle of evolution was placed in doubt.

Manufacturing artificial intelligence and algorithms

Millions of years of evolution may have given human algorithms a head start, but the race is far from over. Whereas we arguably hit peak processing power 100,000 years ago, computer algorithms can already beat doctors at diagnosing cancer and grandmasters at chess. These algorithms are really just getting started when it comes to understanding us.

Researchers at Cambridge and Stanford have shown that with information on just ten Facebook “Likes,” a computer algorithm is more accurate than the average person’s colleague at predicting behavior.

With 150 “Likes,” it could outsmart your family. With 300 “Likes,” it could best a person’s spouse. Perhaps more astounding, the more objective algorithm beat the subject’s own subjective self-evaluation.

Futurists predict a rapid evolution of the algorithms that help guide our online shopping decisions, and even hypothesize that humans may become “an obsolete algorithm.”

Yuval Noah Harari is a historian and author who has written about the relationship between history and biology. He recently published a book called Homo Deus: A Brief History of Tomorrow, in which he discusses the future of humanity and humanity’s relationship with data. He offers an interesting point about humankind’s output:

“If humankind is indeed a single data-processing system, what is its output? Dataists would say that its output will be the creation of a new and even more efficient data-processing system, called the Internet-of-All-Things.”

1. Data from social media will combine with shopping history, and the Internet of Things data to offer predictive shopping support through a Siri-like assistant. Interactions like this may become the norm: “Hey Al, shall I get your favorite beer in? Your friends are coming over tomorrow and the fridge is empty. I better get a 6-pack of non-alcoholic beer for the designated driver, and Laura prefers wine.”

2. These assistants then transition to being an online agent that is a full proxy for the self. As we become confident that the assistant’s algorithms match our own, we will delegate more and more decisions to her. This may include scheduling romantic dates, voting in elections and certainly full control over purchases. We will give our proxy access to our medical history, and real-time data such as heart rate and serotonin levels so her algorithms keep us warm, happy and healthy.

Once billions of agents are active, they will self-organize into powerful purchasing syndicates that will rapidly combine and recombine as viral trends sweep unhindered across the world. Any consumer business still making to stock will find themselves chronically out-of-whack with rapidly changing demands, and only fully digitalized manufacturers will survive and thrive.

We’ve mainly focused on the consumer perspective. Because the mission of a corporation can be more easily codified than that of a person, it’s probable that corporate algorithms in this kind of manufacturing artificial intelligence will quickly evolve, and vendors of industrial products, services and utilities will have their own agent-based marketplace.

If this all seems farfetched, then go speak to your kids. They believe in the freedom of data and have far fewer concerns about a future that unfolds along these lines. They’re already online, sharing everything and establishing the foundation of the agents that will search, shop, order and vote on their behalf.

Lingering questions about artificial intelligence in manufacturing

It’s true that there are still many unknowns about how manufacturing artificial intelligence will work once it’s fully implemented.

• Will giant online corporations like Amazon use their consumer access, cloud-processing power, and supply chain mastery to control our agents and manipulate humanity? Will they become brokers in a giant online marketplace, or will they disappear as technologies like the Blockchain enable a global peer-to-peer economy?

• Will brand owners still manufacture their own products in fixed locations? Or, will intellectual property and manufacturing become disassociated as digitalized micro-factories gain the ability to make anything in close proximity to the consumer?

• What minimum lot size will be economically advantageous for each type of product? Will the dynamics of agent syndicates drive manufacturers toward truly individualized products? Or, will the large numbers of customers in the global market allow manufacturer’s algorithms to negotiate more efficient non-unitary orders?

• Which ‘language’ will agents use to express requirements to manufacturers? Will there be standards that we set, or will machine learning quickly evolve their own semantics?

• Will these ideas only apply to consumer markets, or will corporations have their own agents? A company called Deep Knowledge Ventures has already placed computer algorithms on their board of directors with equal voting rights regarding company policy. And yes, it outperforms its human counterparts.

However this plays out, there are moves manufacturers should be making now to ready themselves as manufacturing artificial intelligence gains ground.

1. Start building online services that algorithms can use to source, configure, price and order products. It will be useful no matter if you directly interact with individual agents, agent consortia or by a broker like Amazon.

2. Digitalize, integrate and automate your ideation (design), realization (manufacturing) and utilization (support) capabilities. This will make your company agile and able to respond quickly to changes in the market or in your customers’ preferences or tastes.

It will make your company’s processes attractive to algorithms, and it will turn your internal value chain into a competitive advantage. Being fast, flexible and efficient is the best preparation for what is to come in Industry 4.0.

3. Start thinking about how you will deliver your products to individual consumers. Amazon has set the bar for acceptable delivery times and continues to be disruptive with 1 hour capabilities rolling out in major cities. The jury is still out about whether customers will pay a premium for customization, but they certainly won’t accept a slower service.

To hit delivery targets, manufacturing will also have to move closer to the customer. In the future, there will be multi-purpose micro factories in each Amazon warehouse, or even 3D-printing replicators in every household. In the meantime, for brand owners who have delegated production to overseas contract manufacturers, that either means finding onshore partners or rebuilding ultra-efficient, in-house production capacity.

For manufacturers, it is not the time to look before you leap. Digitalization is coming fast, and next-generation markets will prize connectivity, transparency, speed and agility. If you don’t prepare now for this exceptionally good AI, you will certainly fall behind your competition – and you may never catch up again.

This concludes our look at algorithms in manufacturing.

About the author

With more than 20 years of experience, first as a manufacturer and then with Siemens, Alastair Orchard has focused on the gains in operational efficiency that Advanced Automation, MES and MOM delivery. He now focuses on Industry 4.0 and the consumerization of manufacturing. Alastair currently leads a global team running the Digital Enterprise Project to help customers take advantage of the synergies possible between product ideation, realization and utilization through the digital transformation of their business processes. Alastair holds an engineering degree in chemical engineering from the Loughborough University of Technology in the U.K. and lives in Genoa, Italy with his wife and four children.