How Industry 4.0 grew out of previous Industrial Revolutions

Digitalization is the process in which companies transform their business by fully integrating digital technology into all business processes. Digitalizing a business does more than putting paper on glass: it weaves a digital thread through the whole value-chain, giving companies the means to realize innovation faster than the competition and to future-proof their business in a constantly changing marketplace.

Digitalization is disrupting the products we buy, the way we choose them and the way we locate and purchase them. Now, it promises to profoundly impact the way they‘re made.

Siemens PLM can turn the challenges in our customers’ industries into an opportunity. According to the American Enterprise Institute, only 12 percent of companies that were in the Fortune 500 in 1955 were still there in 2015. Siemens PLM is a great partner for customers to work with because we can help them flourish at a time when the majority in the market are struggling to survive.

Siemens PLM can turn the challenges in our customers’ industries into an opportunity. According to the American Enterprise Institute, only 12 percent of companies that were in the Fortune 500 in 1955 were still there in 2015. Siemens PLM is a great partner for customers to work with because we can help them flourish at a time when the majority in the market are struggling to survive.

Increased economic growth and industrial revolutions

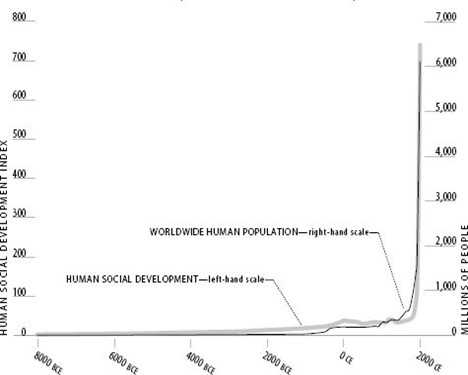

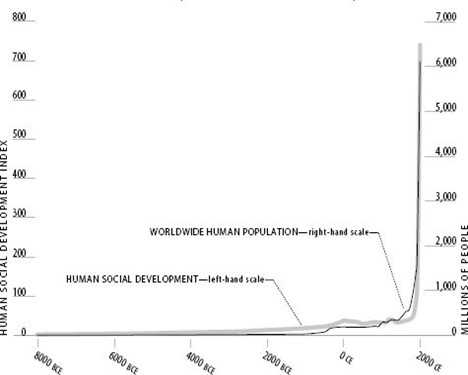

We feel confident about our message because we can go back in history and look at what happened during the first three Industrial Revolutions to put what we’re doing today in the fourth Industrial Revolution, or Industry 4.0, in a bigger context.

There was virtually no progress in human life between the end of the Roman Empire and the late Middle Ages. In his book The Rise and Fall of American Growth, economist Robert Gordon explains that in England between 1300 and 1700, economic growth was only at 0.2 percent per year. Something growing at that rate requires 350 years to double.

Since 1870, the amount of time it has taken for the standard of living to double has been more like 30 years. What accounts for this incredible change?

What accounts for the massive jump in the standard of living?

What accounts for the massive jump in the standard of living?

In his book Sapiens, history professor Yuval Noah Harari explains how, for most of history, money only represented and converted things that existed in the present. This imposed severe limitations on growth. Without speculation, it was difficult to finance new enterprises, and economies remained frozen.

The discovery and exploitation of America showed Europeans that the pool of resources at their disposal could increase over time. This discovery gave them trust in the future. Banks were born. Credit was invented to finance adventures and enterprises. These creations had a knock-on effect on industry.

In 1776, Adam Smith published The Wealth of Nations and explained how wealthier nations fostered a belief in growth. This belief encouraged business owners to reinvest profits in capital equipment and labor, which would increase productivity and benefit all of society.

Within a year, the first truly global generic technology for increasing productivity was invented: James Watt’s steam engine. It was initially applied in coal mines for pumping water, but the increased quantities of coal provided an energy source that would see steam penetrate and revolutionize all heavy industry in Britain over the next century.

By the mid-1800s, steam engines were at the heart of all heavy industry in Britain. Factories looked mostly the same. There was an engine in the basement, a stack for the coal smoke and a tall factory. This factory was driven by an enormous belt that supplied power to five or more floors, where pulleys and shafts drove all manufacturing equipment.

The typical factory setup during the first Industrial RevolutionThis created a massive leap in productivity. But for all of its impact, this was an imperfect revolution. Coal was difficult to distribute and created huge environmental problems for industrialized nations. One massive engine drove all equipment at the same speed and represented a single point of failure. Multi-level manufacturing facilities and complex pulley systems hampered logistic efficiency and literally tied manufacturers to a single type of product.

The typical factory setup during the first Industrial RevolutionThis created a massive leap in productivity. But for all of its impact, this was an imperfect revolution. Coal was difficult to distribute and created huge environmental problems for industrialized nations. One massive engine drove all equipment at the same speed and represented a single point of failure. Multi-level manufacturing facilities and complex pulley systems hampered logistic efficiency and literally tied manufacturers to a single type of product.

Factories don’t look like this anymore, and the reason for that is the electric motor. The first working model came from an entrepreneurial engineer our company knows well: Werner Von Siemens. His 1865 invention would eventually drive a second major Industrial Revolution, but the market was initially slow to adopt the new technology.

By 1900, four decades after Siemens invented the DC electric motor, about 95 percent of factories were still steam powered. The few that used electricity installed these motors as 1:1 replacements of the central steam engines to drive the same old leather belts at fixed speeds. According to economics professor Gene Smiley, it wasn’t until the 1920s that electric motor diffusion passed 50 percent.

Why did it take so long? Well, technology has to mature, companies defend the status quo, existing equipment has to depreciate and business processes get in the way of change.

But once the shift started, it unlocked huge productivity gains: small electrical motors drove individual machines, which allowed radical improvements to the manufacturing process. More companies jumped on the bandwagon. The slower companies’ relative inefficiency soon rendered them uncompetitive and unable to make the transition. None of the steam age manufacturing giants survived to lead their industries into the 20th century.

This story is no different from what we’re seeing with Industry 4.0 because this is what we call the tipping point. It takes time for change to happen, but once we get to a tipping point, change happens really quickly.

Think of it as a skiing analogy. It’s late in the season and temperatures are on the rise. The smart CEOs are already at the beach, but the laggards are still skiing an increasingly unstable snowpack. It’s a beautiful day, and all seems well until the tipping point – and then it all comes crashing down.

Steam, electricity and automation are the three milestones that kept productivity increasing throughout most of the 20th century.

But since the 1970s, overall productivity growth has been dropping off. Why is that?

This concludes part one of our series on how Siemens PLM is addressing the changes Industry 4.0 presents to manufacturing. In part two, we highlight changing consumer tastes and how Siemens PLM has set the bar for Industry 4.0.

Editor’s Note: Readers can watch a free video of Alastair Orchard’s presentation on Industry 4.0 at this link.

About the authors

With more than 20 years of experience, first as a manufacturer and then with Siemens, Alastair Orchard has focused on the gains in operational efficiency that Advanced Automation, MES and MOM deliver. He now focuses on Industry 4.0 and the consumerization of manufacturing. Alastair currently leads a global team running the Digital Enterprise Project to help customers take advantage of the synergies possible between product ideation, realization and utilization through the digital transformation of their business processes. Alastair holds an engineering degree in chemical engineering from the Loughborough University of Technology in the U.K. and lives in Genoa, Italy with his wife and four children.

Dr. Helmuth Ludwig is the executive vice president of Digital Enterprise Realization and chief manufacturing officer for Siemens PLM Software, a business unit of the Siemens Digital Factory Division. Dr. Ludwig has a history of developing and leading successful organizations. He began his career with Siemens in 1990 and started the first Siemens organization in Kazakhstan in 1993. He was the head of Siemens’ Energy and Industry division in Buenos Aires from 1998 until 2001 and served as division president for Software and Systems House and A&D’s Systems Engineering division from 2001 to 2007. Dr. Ludwig served as president of SPLM from 2007 until 2012 and later took on the role of CEO of the Industry Sector USA immediately prior to assuming his current position. Dr. Ludwig holds an M.S. degree in industrial engineering from the University of Karlsruhe, an MBA from the University of Chicago and a Ph.D. from Christian-Albrechts-University in Kiel. He is an adjunct professor for International Corporate Strategy at SMU’s Cox School of Business in Dallas. Today, he is the Chairman of the Board of the Commonwealth Center of Advanced Manufacturing and board member of the German American Chamber of Commerce – South.