Key business process integration for future-proof business

Companies are dealing with many new challenges, including constant market fluctuations and increased complexity. To survive in the marketplace and stay ahead of the competition, most companies realize they must undergo a digital transformation – but aren’t entirely sure how to do it.

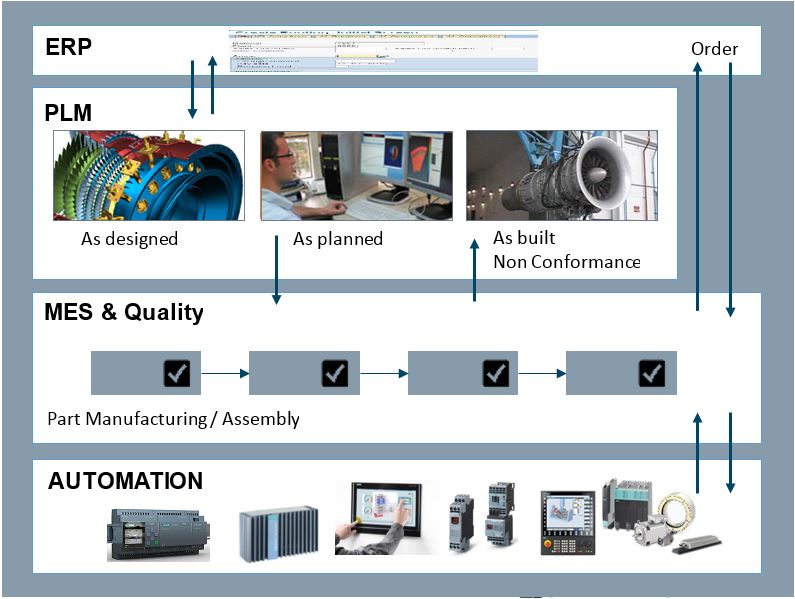

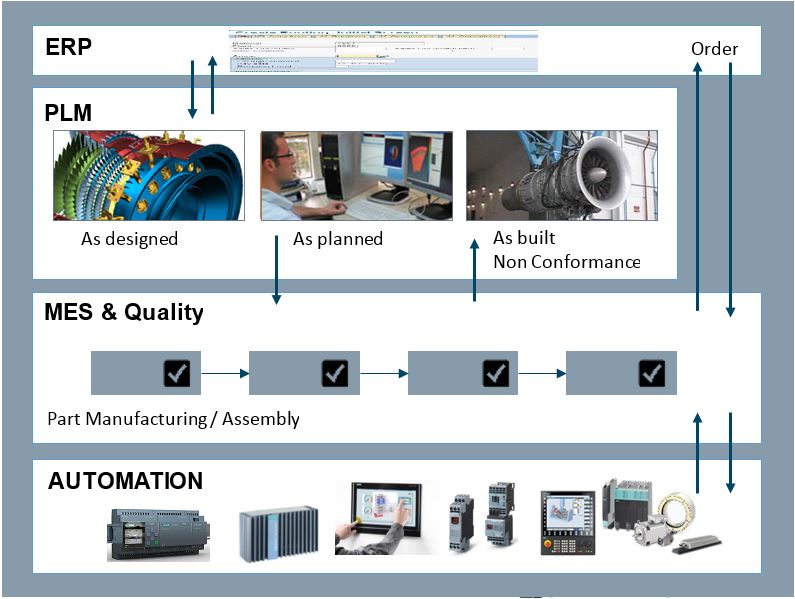

The key to this digital transformation lies in improved business process integration. If companies want to survive and thrive, they must accept that three major enterprise IT systems – enterprise resource planning (ERP), product lifecycle management (PLM) and manufacturing execution systems (MES) – can no longer be treated as separate units. Improving these processes independently will no longer give companies the value they seek.

In his series on creating a closed-loop ERP, PLM and MES process, Matthias Schmich explores how companies can create a digital enterprise to overcome these new challenges. In part one, he discussed how core enterprise systems have typically been developed separately. Here, he delves into why it’s important to treat these systems as complementary pieces in a much bigger whole.

To create a successful digitalization strategy, companies must have a clear concept to integrate their major enterprise IT tools and landscape, particularly PLM, MES and ERP. There are a number of factors to remember when creating this strategy. When addressed successfully, these factors can provide companies increased value for their business processes.

• Increased product complexity requires a new business process integration that will lead to a stronger technical and engineering focus for modules and configurations.

• Future engineering and manufacturing processes should be seamlessly integrated and provide closed loops for learning organizations.

• The decisions for mastering and merging digital product and digital production models is a key element. Business processes, not IT, should drive this.

• The roles and integration of PLM, MES and ERP can be, and should be, industry-specific.

• The interaction between the essential domains will affect product validation processes, virtual commissioning and manufacturing integration. And,

• A tight business process integration of PLM, MES and ERP will be able to offer significant value for faster time-to-market, reduced costs and improved quality.

The basis for being able to quickly and effectively respond to new market scenarios lies in a business-aligned interaction of PLM, MES and ERP. This interaction enables companies to keep flexible, dynamic and success-oriented goals in fast-changing markets. If these systems are connected between the different domains, companies can build closed-loop processes and have vital information flow in more than one direction.

PLM of today vs. PLM of the future

Today, PLM is a business strategy that focuses on engineering. It pursues methods, processes, organizational structures and system technologies, and it maps all product-related contexts in a coherent solution. This will change in the future.

In the future, PLM will cover the entire product lifecycle and value chain: from requirement/ideation, to engineering, to manufacturing, to operation and to service and maintenance. PLM will also offer decision support, which will be the foundation for simulating the real world in digital and virtual models. With all of these changes, it’s important to realize that PLM’s interaction with ERP and MES will also change.

All involved engineering disciplines must be able to link their data and processes together. This includes more than mechanics; this includes electronics, electrical, software, automation and documentation. Everyone must be able to collaborate along the product value chain; this includes final product manufacturers, original equipment manufacturers, suppliers, partners and customers. They will work on one platform to bring the digital product data together and to establish a digital twin, which will allow them to test products in the virtual and physical worlds.

This digital transformation will result in more productive processes and more optimized products, which will play a significant role in getting to market faster than the competition.

Companies that experience this transformation will have more productive processes and optimized products, which will help them get to market faster than their competition.

Companies that experience this transformation will have more productive processes and optimized products, which will help them get to market faster than their competition.

Implementing better business process integration

Each PLM solution can have an industry-specific characteristic, and they will quite often have company-specific usage. PLM solutions should be based on a strategic concept and plan, which always requires adapting the solution to address a company’s individual circumstances and constraints.

This capability is different than what ERP offers. ERP systems aren’t typically designed to change core processes; they’re restricted to managing data in early engineering and design phases because they have a monolithic architecture and a transactional data processing. A dedicated digital enterprise solution handles a number of processes. Information flows for all technical product data and in early engineering phases. This is one reason why companies need a Digital Enterprise Platform with PLM and MES, closed-loop processes and ERP integration: it’s essential for a successful digital transformation.

ERP systems are focused on administrative business management, logistics or finance business processes based on released data and transaction processes; most ERP systems aren’t capable of managing technical product data. This is where a digital enterprise platform can help because it is designed exactly for this. This platform promotes better technological innovation with its iterative, heuristic approach and is far superior to what purely ERP solutions offer.

A digital transformation eases product variety, customization management

We’ve witnessed the transition from a seller’s market to a customer’s market, and we’ve seen a steady increase in product variety and personalization over the last several years. These changes are requiring companies to create new platform strategies and mass customization methods on a system with exceptional technical support.

Today’s digital enterprise platforms offer powerful mechanisms to manage product variety and to manage complexity. The PLM system manages product structures and configurations for products from an engineering perspective. This ensures optimizations in manufacturing and assembly lines. ERP manages configurations from a sales perspective. If both are not aligned companies will have issues in downstream processes. One view on configuration starting from engineering in PLM should control other configurations like in sales, which is typical in ERP. Both configurations have to be aligned by the connection of PLM and ERP.

The benefits of having a PLM and ERP integration strategy are found in PLM functionality along the value chain to manage variety and complexity until the service and aftersales stages. But there’s still a gap in operational execution.

The benefits of this business process integration are seen along the value chain when managing variety and complexity — but there are still gaps.This is why MES is so crucial to this business process integration: MES can bridge that gap. Its strength is real-time data processing in production environments. The key to efficient production is being able to complete tasks as soon as possible.

The benefits of this business process integration are seen along the value chain when managing variety and complexity — but there are still gaps.This is why MES is so crucial to this business process integration: MES can bridge that gap. Its strength is real-time data processing in production environments. The key to efficient production is being able to complete tasks as soon as possible.

MES enables connectivity to physical devices, provides instructions to guide the workforce and enables traceability without interruption. And, it shares that data and information with ERP and PLM. With this information, PLM and MES evolve and become the knowledge base for the product, its production planning and its manufacturing.

PLM becomes the technical backbone. It will be the basis for forward-looking decisions based on digital simulations, production facility investments or deciding which processes to optimize. In this layer, all rich information for business decisions or executional behavior is available. Integrating PLM and MES brings the experience and the ability to the technical level. With seamless business process integration in a closed loop, companies can leverage the operating value in this technical field, for example, to track and trace all product configurations like “as built” in PLM.

ERP’s important role for all logistic/financial business processes will still remain. But the ownership of product and production data in the leading Digital Enterprise Platform will cause ERP to eventually integrate. And to prepare for that integration, companies must begin adapting and even reducing their current processes in ERP.

A closer look at how this business process integration enables a company’s digital transformation.This concludes part two in our series on the importance of creating a closed loop PLM, MES and ERP process. In part three, Matthias Schmich continues to explore how the future will look if companies take this approach to linking the systems together and how Siemens PLM is poised to help its customers benefit from this business process integration.

A closer look at how this business process integration enables a company’s digital transformation.This concludes part two in our series on the importance of creating a closed loop PLM, MES and ERP process. In part three, Matthias Schmich continues to explore how the future will look if companies take this approach to linking the systems together and how Siemens PLM is poised to help its customers benefit from this business process integration.

Tell us: How do you think your company would benefit from a business process integration like the one described here?

About the author:

Matthias Schmich has more than 30 years of experience in multiple management positions and has expertise in founding a company, managing IT and consulting. Matthias studied computer science in Karlsruhe from 1980 to 1984. He started his career at Robert Bosch and soon co-founded the Eigner Company, where he was one of its presidents. In 1993, Matthias moved to Müller Weingarten, where he was the IT manager for five years and was responsible for the company’s IT processes. He then joined Andersen Consulting and founded the company C´vis Consulting soon after, where he was responsible as the external program manager for global PLM initiatives. From 2004 until 2008, he was the head of business consulting at AGILE/ORACLE. Since 2008, Matthias has worked for Siemens Industry Software, first as the EMEA project management office manager and then as the vice president for services in Germany until 2014. He is currently the vice president for strategic business in the German Zone and focuses on Industry 4.0 and the digitalization of the value chain.