How to measure ISO 26262 metrics of analog circuitry

By Stephen Sunter – Mentor, A Siemens Business

ICs designed for safety-related automotive systems are expected to operate safely for the lifetime of the vehicle. The manufacturing test strategy and on-chip runtime test capabilities are important aspects of achieving that zero-DPPM goal.

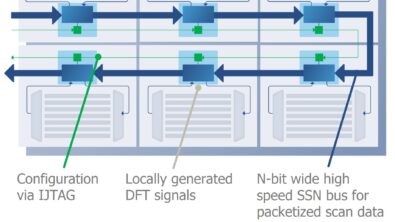

Much discussion of test and diagnosis for automotive ICs addresses digital logic and memories, but most (70% or more) of the field failures occur in the mixed-signal portion of the chip. These defects, even in small numbers, can’t be tolerated in safety-critical automotive applications. Mentor developed the Tessent DefectSim analog defect simulator to address this growing need for analog test tools. Tessent DefectSim automates the job of measuring a circuit’s tolerance to defects.

The ISO 26262 standard provides for defect tolerance. Since the focus of the standard is minimizing the likelihood of unsafe failures, the likelihood of each fault/defect must be estimated to be able to compute these metrics. The metrics include:

- Single point fault metric (SPFM)

- Probabilistic metric for random hardware failures (PMHF)

- Residual faults (DC-Residual)

- Latent faults (DC-Latent)

- Latent fault metric (LFM)

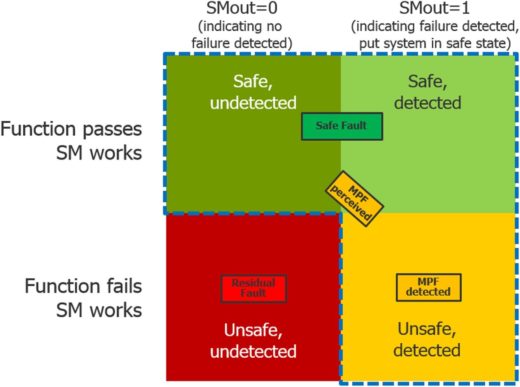

All but LFM can be measured by Tessent DefectSim by injecting on defect at a time. LFM cannot be measured by injecting one defect at a time since, by definition, latent defects do not individually cause any failure. With Tessent DefectSim, a two-step procedure is used to overcome this limitation when measuring LFM. Figure 1 shows a simplified Venn diagram of the different outcomes of simulated injected defects.

Tessent DefectSim automatically measures all these metrics. It can also simulate entirely digital circuits but inject transistor-level defects instead of gate-level stuck-at faults. This allows IC designers to provide an automated and objective assessment of likelihood-weighted defect coverage and defect tolerance, in less time, when these metrics are required by Tier 1 automotive customers.

For details on how Tessent DefectSim measures the fault metrics for analog circuits, download the whitepaper Measuring ISO 26262 Metrics of Analog Circuitry in ICs.