Washington Post features how Siemens digital twin technology is helping reimagine the future of modern manufacturing [ARTICLE]

Manufacturing is entering a new era, one where factories are designed, tested, and optimized long before a single piece of equipment is installed. In a recent Washington Post article, “The Digital Twin Age: Using Simulations to Boost Real-World Business,” journalist Jason Dan, Lead AI & Tech Analyst, explores how digital twin technology is transforming the way companies plan and operate industrial facilities.

At the center of this transformation referenced is Siemens, whose digital twin capabilities are helping manufacturers move faster, reduce risk, and rethink what’s possible in modern production.

From static designs to living factories

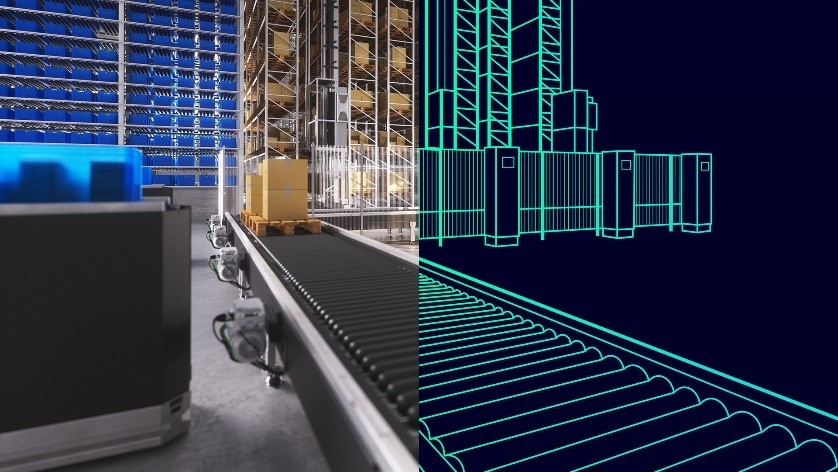

The Washington Post article describes the evolution of digital twins, a technology that Siemens has championed. Imagine building a complete production facility in weeks rather than months, experimenting with dozens of virtual layout configurations, and getting robotic systems ready long before the first piece of equipment ever reaches the floor. This isn’t a far-off vision; it’s something Siemens has already demonstrated in real time.

Today’s digital twins are dynamic, predictive, and continuously updated, mirroring real-world facilities in real time. These virtual environments allow manufacturers to simulate production flows, identify bottlenecks, and fix design issues before construction or launch, rather than discovering problems after costly delays. This shift is fundamentally changing how companies plan and run physical operations, making factories more reliable, efficient, and resilient.

Shortening time to production with digital twin technology

One of the article’s most compelling examples highlights an advanced AI-server electronics manufacturing facility. Using technology from Siemens and NVIDIA, the electronics manufacturer was able to bring its plant online in just seven months, compared to the typical one-to-two-year timeline. Learn more about the Siemens and NVIDIA collaboration in our latest blog. As the Washington Post article notes, this dramatically shortened planning-to-production cycle is becoming a strategic asset for U.S. manufacturing, particularly as companies look to localize advanced production.

By leveraging digital twins, the electronics manufacturer can:

- Virtually design and test factory layouts

- Optimize equipment placement and throughput

- Identify design flaws before physical commissioning

The Siemens Digital Twin Builder in action

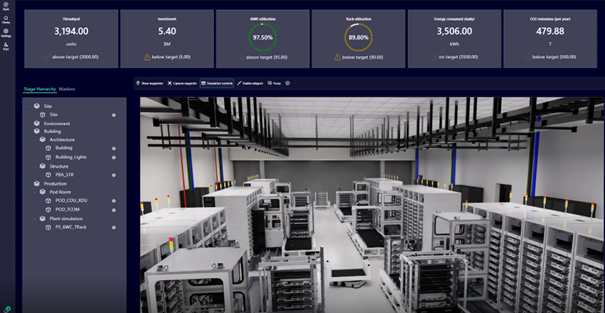

During the demonstration referenced in the article, Siemens showcased a solution that is in development known as the Digital Twin Builder, which provides a single, unified, immersive environment that combines comprehensive digital twins, industrial AI, physics-based simulation, advanced visualization, and live factory data.

At the core of the Digital Twin Builder are products from the Siemens Xcelerator portfolio, including Plant Simulation which is used to optimize material flow, production throughput and equipment utilization, and Process Simulate to validate automation behavior and control logic before physical commissioning. Siemens Designcenter software, Teamcenter software and Simcenter software also play a role in supporting early factory layout exploration, maintaining the trusted lifecycle data and enabling AI-driven design optimization across the digital twin lifecycle.

Siemens Digital Twin Builder is built on Mendix, the low-code platform that enables rapid customization and seamless integration into existing engineering environments. This foundation allows teams to adapt the solution to specific workflows, systems, and use cases with minimal development overhead.

By unifying design, simulation, and operations into one living model, the Digital Twin Builder helps eliminate silos between teams and enables faster, more confident decision-making. In the use case, Siemens demonstrated how architects, manufacturing engineers and automation teams could:

- Place virtual equipment into a realistic digital model of a planned server-testing room

- Simulate operations to test chiller placement and server flow

- Validate decisions long before physical assets exist

Why Digital Twin technology matters for U.S. manufacturing

The Washington Post frames the digital twin as a critical enabler for America’s manufacturing ambitions and Siemens is proud to help customers accelerate their digital transformation with digital manufacturing technology that can:

- Shorten the time from planning to production

- Reduce costly disruptions

- Support advanced robotics and “physical AI”

- Help address persistent labor shortages through greater automation

As Todd Bengtsson, Director of Manufacturing Portfolio and Strategy at Siemens Digital Industries Software, explains in the article:

The pace at which things are happening is like nothing else I’ve ever seen. Being able to apply the right technology in the right place, and not misuse it in the other areas, is something we’ve all got to discover.“

Momentum across modern industries — and what’s next

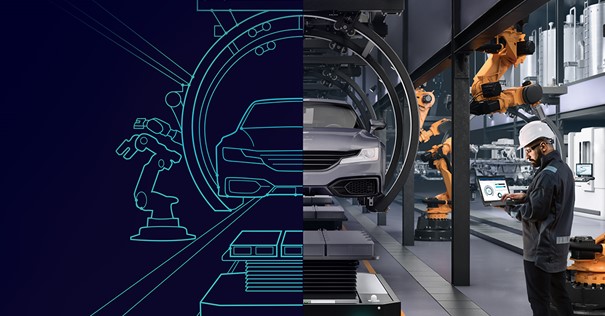

While the Washington Post article acknowledges challenges, particularly the availability of high-quality data needed to build realistic digital twins, it notes rapid adoption across industries, especially automotive. Major automotive manufacturers use virtual factories to reduce planning costs and simplify complex production changes.

The article closes by pointing to what’s ahead: Siemens, a pioneer in industrial technology, is betting big on digital twins, with CEO Roland Busch expected to announce new developments at the upcoming Consumer Electronics conference (CES) in Las Vegas. Stay tuned to hear the latest of what will be unveiled at CES on January 6-9, 2026.

This recap only scratches the surface of how digital twin technology is reshaping manufacturing, and how Siemens is helping lead that change.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)