Students use Tecnomatix to design, analyze and manage complex systems

Educating engineering students for the digital age

The Industrial and Systems Engineering (ISE) department at Oakland University (Auburn Hills, Michigan) joined Siemens’ global academic partner program in 2009. The department prepares students for Industry 4.0.Through the program, the department obtained the Tecnomatix portfolio of digital manufacturing solutions (including the Plant Simulation solution, Jack software and the Process Simulate solution) and Teamcenter software tools, as well as training and support. These and other PLM tools were integrated into several existing courses such as Introduction to Industrial and Systems Engineering, Ergonomics and Work Design, and Computer Simulation of Discrete Event Systems. In these courses, students are given assignments that require the use of PLM tools.

Dr. Megan Conrad, assistant professor of industrial and systems engineering, notes: “The use of Jack in the classroom allows our students to visualize ergonomic issues in another dimension. The students not only see how the worker fits in the customized workspace, but simultaneously can compare timing and throughput information while minimizing risk factors like low back injury and unsafe joint postures. Gaining hands-on experience using the Siemens PLM Software solutions has made our students desirable to many companies. Several of our ISE students have found positions working in digital human modeling even prior to graduation.”

“We receive very positive feedback from students and employers upon assessing the use of PLM tools in existing courses,” says Dr. Robert Van Til, Pawley Professor of lean studies and chair of the Industrial and Systems Engineering department. “But one issue was clear: while the students were learning how to use and apply these PLM tools to particular problems, there was a desire to take a deeper dive into the tools themselves and their use in engineering design and analysis. Feedback from both students and employers noted that it would be valuable to learn more about how the tools operate and how they are used.”

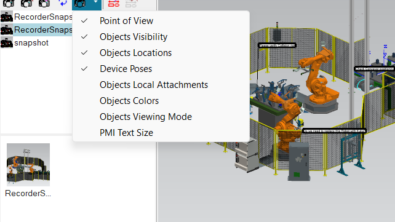

This assessment led to the development of several PLM courses with a focus on applications. These courses consider how to use a particular PLM software tool, followed by the use of the tool on several assignments. Four such courses have been developed and offered to date: PLM Applications – Product Data Management (Teamcenter); PLM Applications – Robotics (Process Simulate Robotics); PLM Applications – Ergonomics (Jack); and PLM Applications – Change Management (Teamcenter).

The Industrial and Systems Engineering department, with the assistance of Oakland University’s Pawley Lean Institute, is working to bridge the gap between industry’s need for work-ready, highly skilled engineers and the availability of students who identify engineering as a career path of choice. Together, they have developed a pilot science, technology, engineering and mathematics (STEM) outreach program that pairs ISE students and faculty with K-12 students and their teachers in a successful, interactive program that is providing hands-on experiential learning in a university setting.

The program has been conducted over the past three years with the intent of introducing industrial and systems engineering as a potential career path for K-12 students. It currently consists of visits to ISE department facilities and laboratories on Oakland University’s campus by classes of high school students and their teachers. Distance-learning techniques may be implemented in the future to expand the program’s reach beyond southeast Michigan. The high school students work with ISE students and faculty and with volunteers from local companies to conduct hands-on projects focusing on the areas of lean manufacturing and PLM.

Assessment of the K-12 STEM outreach program has been very positive from student attendees, their teachers, and parents who have attended the sessions. Doug Blatz, Seaholm High School teacher and recipient of a 2015-16 Albert Einstein Distinguished Educator Fellowship, notes, “Seaholm High School students are enrolled in a course called STEMx Research and Design. The course develops research and engineering methodologies while embedding students in externships with professionals from the surrounding area. One of the initial externships we developed involves a learning experience with Oakland’s ISE department. Our students have had a very positive experience while participating in simulations that involve industrial and systems engineering applications. For example, students are introduced to the Jack software program, which provides design protocols concerning ergonomics. Our students are also exposed to career pathways in product lifecycle management. The ISE Department has established a long-term STEM partnership with Seaholm and other high schools involving PLM activities.”

You can read the complete story about how Oakland University is educating students for the digital age here.