Siemens simulation software helps students see their future

Many students come to Clemson University (Clemson, South Carolina) for the opportunity to learn through hands-on experiences in an academically challenging setting, but for graduate students in automotive engineering, who are learning how to optimize vehicle production, being hands-on is a little more challenging.

In the automotive manufacturing systems class in Clemson’s College of Engineering, Computing and Applied Sciences, Clemson adjunct professor Joerg Schulte assigns his class to work in teams to design a complete automobile production system, in other words, factories, from the press shop to the body shop to assembly.

“We can’t build that up in reality, so in order to get as close to reality as we can I’ve been using the plant simulation software package from Siemens,” said Schulte, who also is manager of the BMW Liaison Office for Research and Innovation. In November 2016, Siemens, a global technology company, presented Clemson with its largest gift-in-kind, product lifecycle management software with a commercial value of $357,224,294.

With the software available to all students, the Automotive Manufacturing Systems class had a project component for the first time in the fall semester 2016. “Without this software, it wouldn’t be possible for the students to really get to the detail of what it means to run a production system – how many stations and workers are needed, what kind of cycle time each station has, how to sync material supplies, etc.,” Schulte said.

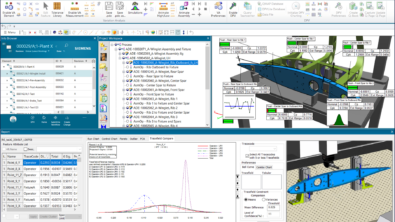

With the simulation software, engineers can “test drive” their designs and run a few months of automobile production in a matter of hours. After evaluating the results against target performance indicators the students make adjustments to variables in production, labor, layout and other factors that are relevant to a production line.

“They not only improve the performance of their system with each run, but even more importantly, they improve their understanding of the complex production system,” Schulte said. At the end of the semester, the student teams present their projects, complete with 3-D simulation models built using the Siemens software, at the Clemson University International Center for Automotive Research (CU-ICAR). Corey Benson, a 2016 Clemson graduate who is now an engineer with BMW, said having access to the Siemens software gave him a head start in his career.

“It helped me learn how to interface with the software before getting to the plant,” Benson said. “And it’s also a software that’s used all over America and Europe, so it’s definitely a good resource to know.” Current engineering student Surabhi Sharma says the new software is one more reason Clemson excels in automotive engineering. “I came to Clemson because I’m passionate about cars and I really want to do something in futuristic automobile technology,” Sharma said. “Clemson is considered to be the best place, and right now I’m experiencing it with the help of the faculty and the labs and other resources.”

CU-ICAR’s Deep Orange program, in which student-led teams engineer and build cars, has proven to be a very motivating and successful teaching method for product design, Schulte said. The combination of classroom learning and project implementation in Schulte’s automotive manufacturing systems class complements the Deep Orange approach for production design, albeit on a much smaller scale.

Follow this link to the video.