Shaping the Future of Aerospace & Defense: Human-Centric Design at Northrop Grumman

From digital simulation to mission-ready systems, explore how Northrop Grumman is transforming aerospace and defense design to assembly process with human-centric digital manufacturing software to ensure safer, more efficient designs before a single part is built.

Few industries move faster, or demand more precision, than aerospace and defense. Designs can change overnight, compliance requirements tighten without warning, and mission needs evolve at a relentless pace. At Northrop Grumman, that challenge comes with an added responsibility: ensuring every aircraft system is not only technologically advanced, but also human-centric — designed to be accessible, maintainable, and operable by human workers of all shapes and sizes. Operating a military aircraft is one of the most expensive commitments in defense. Layer on the ever-growing complexity of aerospace hardware and design, and the stakes rise even higher. A single misstep during design can ripple outward into a cascade of production delays, mounting expenses, and long-term maintenance challenges.

That’s why Northrop Grumman has turned to Siemens Process Simulate Human software, brought to life inside the HIVE (Highly Immersive Virtual Environment). Together, these digital tools give engineers the ability to collaborate globally in real time while simulating human interactions with complex systems before they’re ever built. Hear from Northrop Grumman’s Systems Engineer, Sibo Chou, to explore how the aerospace and defense leader combines Siemens Process Simulate Human with motion capture technology to bring a human touch to the design to aircraft assembly process.

Advanced ergonomic process simulation at Northrop Grumman

As a global leader in aerospace and defense industry, Northrop Grumman is known for pushing the boundaries of innovation — from advanced aircraft and autonomous systems to space exploration and cyber defense. But delivering breakthrough solutions requires more than next-generation designs; it requires flawless collaboration, and a design philosophy centered on the people who will ultimately use, maintain, and operate these systems. As Chou explains, ‘“We have teammates all over the country and world. We really needed a tool that allows us to collaborate a little easier between the customer, the employers, and our suppliers.”

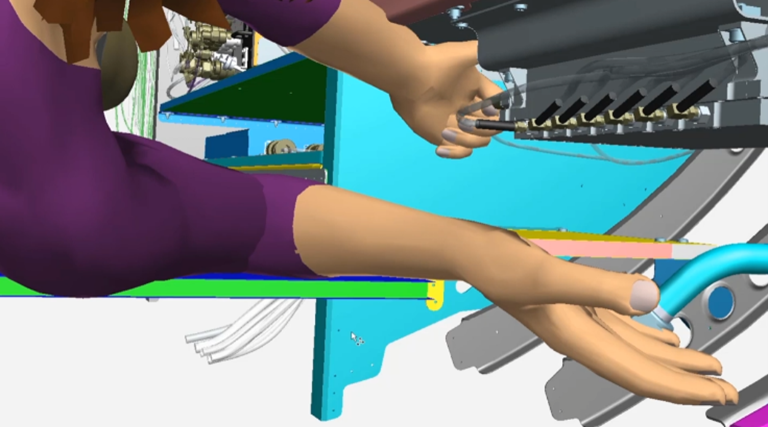

That’s why Northrop Grumman uses Siemens Process Simulate Human software combined with the HIVE (Highly Immersive Virtual Environment), a virtual hardware testing system that uses motion capture for engineers to interact with designs, to identify risks upfront, reducing rework and ensuring lasting savings in cost, time, and effort. By stepping into a virtual build environment, engineers can interact directly with 3D models of aircraft, testing assembly and maintenance tasks before a single part is fabricated. The payoff is enormous: design flaws are caught early, saving exponential amounts of time, cost, and effort across an aircraft’s entire lifespan, while optimizing for human ergonomics and usability from the very beginning.

Optimizing for human-centric design for aerospace and defense

Beyond the logistics of teamwork lay an even deeper challenge: the human element. Designs, no matter how brilliant, must ultimately be built, maintained, and operated by people. And as an aerospace and defense contractor, Northrop Grumman must ensure their aircraft parts can be handled, installed and maintained by a diverse range of human sizes.

To tackle these intricate challenges, Northrop Grumman turned to Siemens Process Simulate Human software and the HIVE to stream motion data directly into Siemens digital manufacturing software. Think of it as a virtual test lab where engineers can simulate, whether — and with how much difficulty —operators can access different parts of an aircraft during assembly, enabling detailed ergonomics studies, and even creates immersive virtual reality (VR) simulations. By leveraging Siemens Process Simulate Human software, Northrop Grumman can significantly decrease lengthy and costly physical testing periods, moving from concept to confidence faster than ever before.

We are using the HIVE to conduct human factor studies for manufacturing, maintenance and operations using the digital twin,” Chou explains. “And we’re doing all of this before we cut any metal or cure any composite.”

Sibo Chou, Extended Reality Engineer, Northrop Grumman

Sibo and his team can now digitally conjure any human size specified in a contract. They can then watch, in a virtual environment, as this digital human performs the task. And the efficiency of the software speaks volumes. What once took hours of effort can now be done almost instantly. “With the HIVE and Process Simulate Human,” Chou explains, “we’re able to generate a new posture every second.” That kind of speed transforms what’s possible — allowing teams to explore a record range of scenarios, from reaching a fastener deep inside a fuselage to handling a fuel pipe, all tested virtually to ensure safety, accessibility, and flawless design.

A Seamless End-to-End Connection for Aerospace Innovation

What truly elevates this experience is the seamless integration of Siemens software ecosystem that Northrop Grumman uses from Siemens Xcelerator portfolio, including NX, Teamcenter, and Process Simulate software, which connects every stage of the product lifecycle into a single digital thread.

Teamcenter serves as the backbone for product lifecycle management and collaboration, NX provides advanced design and engineering capabilities, and Process Simulate enables precise virtual validation of manufacturing and human ergonomics. Together, Northrop Grumman uses Siemens interconnected ecosystem that links design, engineering, and manufacturing so that data flows without barriers, changes are managed in real time, and every decision is informed by a complete digital twin.

For Northrop Grumman, it means greater speed, accuracy, and confidence — from concept to production to long-term mission readiness. Chou helps paints a picture of this fluid software workflow: “If a designer has an issue, they give us a call, they give us a part number or a series of part numbers, we go directly into Teamcenter and we pull those models into Process Simulate.”

Using NX, Teamcenter and Process Simulate with the HIVE enables us to quickly do assessments and efficiently push those changes to the rest of our program.” –Sibo Chou, Extended Reality Engineer, Northrop Grumman

From there, the assessment begins. If a design tweak is needed, it’s a quick hop into NX to make the change, then right back into Process Simulate for re-analysis. “It’s an iteration process,” Chou emphasizes, “and we can do that really quickly.”

Driving Aerospace and Defense design to manufacturing process efficiency at scale

By embedding immersive technology into daily operations, Chou explains how the HIVE with Process Simulate Human saves precious time that translates into faster delivery and more efficient production.

We cut down 25 days of production in one of our products per unit,” explains Chou.

This success isn’t confined to a single program or site. With more than 20 HIVEs now deployed across the country, Northrop Grumman is demonstrating the power of digital engineering-to-manufacturing at scale. By leveraging virtual human-centric design, Sibo Chou and the Northrop Grumman team are doing more than creating advanced systems; they’re pioneering a new operational paradigm where engineers and operators can anticipate challenges before they occur, validate designs across the product lifecycle, and accelerate delivery with confidence. This is the future of aerospace and defense: innovation that secures the mission, strengthens the enterprise, and proves the power of seeing tomorrow’s challenges — and solving them — today.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)