Production Simulation and Energy Efficiency in the Automotive Industry

For automobile manufacturers, energy efficiency goes well beyond ensuring that their vehicles use less energy to operate. Today there is an additional focus on creating energy and resource efficient factories. In this presentation, “Production Simulation and Energy Efficiency,” by Dr. Ulrich Rossgoderer, Digital Factory Division, Siemens PLM Software, describes how manufacturers can utilize simulation models to help analyze scenarios that will achieve energy and resource savings.

The complete presentation is attached. This was originally presented at the annual Energy Efficiency in Automobile Production conference on February 24, 2015. Read the highlights of the presentation and let us know what you think.

Challenges for the industry are growing worldwide

Siemens is strengthening its customers’ competitiveness by reducing time to market, increasing flexibility and increasing efficiency. Siemens has the right answers to the challenges of its customers in the manufacturing industry. Siemens’ portfolio of software solutions seamlessly integrates development, production and suppliers, paving the way for the digital enterprise.

Production Simulation and Energy Efficiency

Not only the CO2 emission during the use of a product is relevant but also the CO2 emission spent during manufacturing process. Therefore manufacturing companies are giving more and more attention to energy efficiency of their factories. Besides using smarter and more energy efficient equipment, the manufacturing processes themselves can be optimized for energy efficiency as well. Digital Models should help to analyze various energy saving scenarios without disrupting running production.

Robotic Energy Simulation Motivation

At Siemens, we are focused on two areas for energy consumption simulation: 1) robotics industry; 2) logistics material flow. We will start with robotic energy simulation. Typically there are huge amounts of robots in car production. The goal is to save energy per robot and scale-up over the full line. To determine how to operate robots more efficiently, production simulation software will look at motions of robots being programmed considering collision and cycle time only; no consideration of the ergonomics of a robot. Dynamics of motion and position of robot has significant influence on energy consumption. By measuring and displaying energy consumption, programs can be optimized both for time and energy.

Robot Energy Saving Scenarios — Influence of Path Smoothness

Studies conducted aas part of the Green Car Body research project have shown that it’s possible to save 35 percent of robot motion energy by improving the smoothness of trajectories.

Robot Energy Saving Scenarios — Influence of Motion Height

The same Green Car Body studies have shown that favouring of low arc trajectories over high arc trajectories can lead to robot motion energy saving of 61 percent.

Robotic Energy Simulation — Enable Energy Measurement in Robot Simulation

- Display energy consumption in robot simulation systems

- Consider energy values during robot offline programming

- Consortium of users, robot vendors and simulation vendors

- Agreed on a set of extensions to existing standard (RRS-1).

- Proposed extension is already being implemented by some of the consortium members

Robotics and Simulation Planning

RRS is a well-established standard protocol (since 1994) enabling realistic simulation of robot motions using the robot vendor specific algorithms encapsulated as black-box. Membership includes a variety of manufacturers and simulation suppliers in support of all robotic and automation applications.

RSS Extension – Key Capabilities

New function calls for: 1) Definition for robot energy state and transition; 2) Set robot energy state for controller; 3) Set energy saving level for robot controller (as available); 4) Calculate total energy consumption for a given time interval; 5) Optional: provide energy consumption break-down by system element

The accuracy of energy values depends on the RCS module implementation done by the robot vendors.

Siemens PLM has released virtual measurement capabilities with Tecnomatix 12.

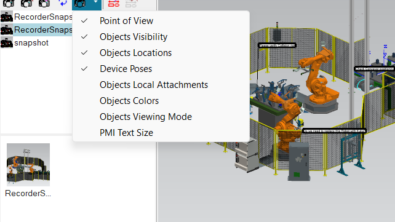

Siemens’ implementation in Process Simulate enables the user to connect to the RCS Module of KUKA (available only on KRC8.3) and “read” the energy consumption values during simulation. Running the robot simulation while it is connected to the specified RCS module, the user can view the following information:

- A momentary power consumption of the robot during the simulated operation. This information is displayed as a dynamic graph during the operation run.

- The overall energy consumed by the robot during the simulated operation. This information is displayed as a static value after the operation run.

- The peak power consumption of the robot during the simulated operation. This information is displayed as a static value after the operation run.

Future development includes more assistance and optimization for energy optimized motion generation.

Energy Simulation of Complete Manufacturing Systems

In parallel to providing ways to visualize and optimize robot energy consumption, Siemens PLM software also allows for the corresponding simulation of complete manufacturing systems. This allows for testing and validating energy control strategies e.g. for machining lines in Automotive Powertrain, assembly lines for LCD etc.

Tecnomatix Plant Simulation Software

Tecnomatix Plant Simulation allows you to model, simulate, explore and optimize logistics systems and their processes. These models enable analysis of material flow, resource utilization and logistics for all levels of manufacturing planning from global production facilities to local plants and specific lines, well in advance of production execution. Extensive analysis tools, such as bottleneck analysis, statistics and charts let you evaluate different manufacturing scenarios. The results provide you with the information needed to make fast, reliable, smarter decisions in the early stages of production planning.

Energy Related Machine Settings

Plant Simulation introduces energy related parameters for machine and transportation objects according to the PROFIenergy standard. Plant Simulation provides the introduction of energy consumption levels for working, operational, and stand-by modes, and tracking of overall energy consumption profiles. The benefit is the ability to evaluate and optimize the production process according to energy related issues.

PROFIenergy: Smart Energy Management over PROFINET

Tecnomatix Plant Simulation supports testing of control strategies for manufacturing systems aligned with the PROFIenergy standard.

Tecnomatix Plant Simulation — Energy Settings and Power Management

- Energy consumption of machines and conveyors

- Switching times for powering on/off

- Energy related statistics

- Automatic state change according to shift calendar

Reducing lifecycle energy consumption of car engines with Plant Simulation

BMW found that with little engineering effort, they could achieve significant savings through the use of digital models. In the existing model of the line created using Plant Simulation, all that it takes to get a valid energy simulation is to map the information on the power consumption of each machine in the line with the production stages in the process control system, and to add it as a list to the existing simulation model. As the energy simulation functionality is a standard feature of the package, getting presentable results took only two weeks, requiring no investment in software. Based on the energy simulation, in which the car engine makers were assisted by German simulation service provider iSILOG GmbH, various scenarios were tested in the virtual production environment model created using Plant Simulation.

- Saving 1.66 Mio kWh per year through “start-stop” control strategy for machines

- Measurement did match simulation prediction

- Additional 1.4 Mio kWh saving through turning of high-pressure pumps for cooling lubricants in case of idling machines

- Positive side-effect: noise reduction

Plant Simulation Energy Simulation Summary

Energy consumption will be a major differentiator for competitive bidding and key criteria for manufacturing production and facility related decisions. Tecnomatix Plant Simulation offers an off-the-shelf toolset for manufacturing production: modeling, simulation and analysis, and experimentation and optimization. Energy simulation allows you to easily analyze and manage energy consumption in complex, dynamic production environments.

To learn more about Tecnomatix Plant Simulation, visit our website.