Polygon Technologies reduces onsite commissioning time by 70 percent

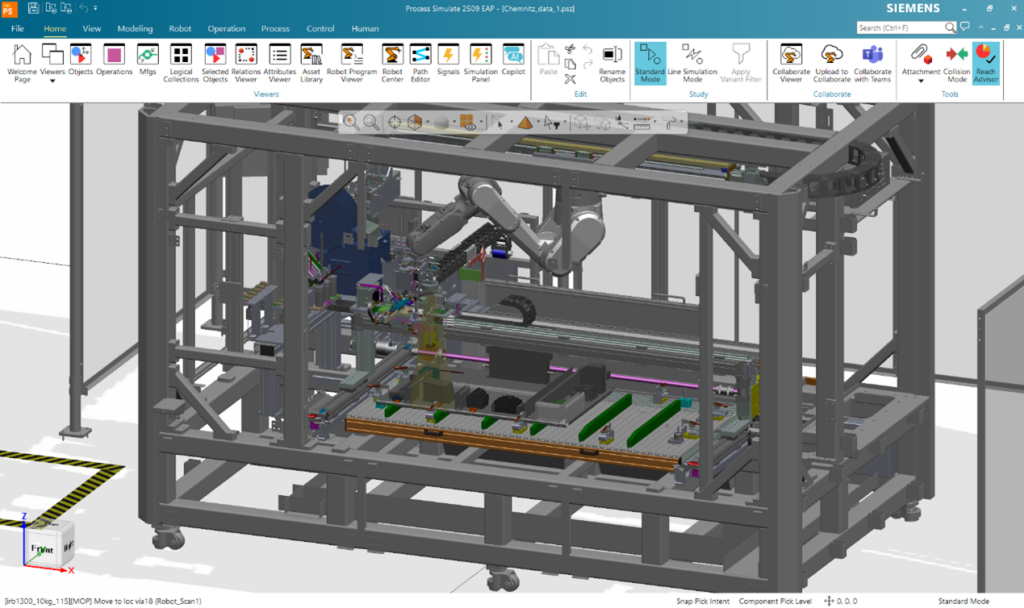

Optimizing Wire Harness Assembly with Process Simulate

For over two decades, Polygon Technologies has been at the forefront of robotic automation, delivering cutting-edge solutions that streamline manufacturing, reduce costs, and enhance productivity. Based in Zur Yigal, Israel, Polygon specializes in advanced robotics and automation systems for industries such as automotive, aerospace, electronics, and industrial manufacturing. Their latest innovation, Wirebot, is transforming the traditionally manual process of wire harness assembly with a highly automated and precise robotic solution.

Explore how Polygon leveraged Siemens Process Simulate, to help enable virtual commissioning and process optimization. The result? A 70% reduction in onsite commissioning time, a 60% decrease in rework, and a significant boost in production efficiency.

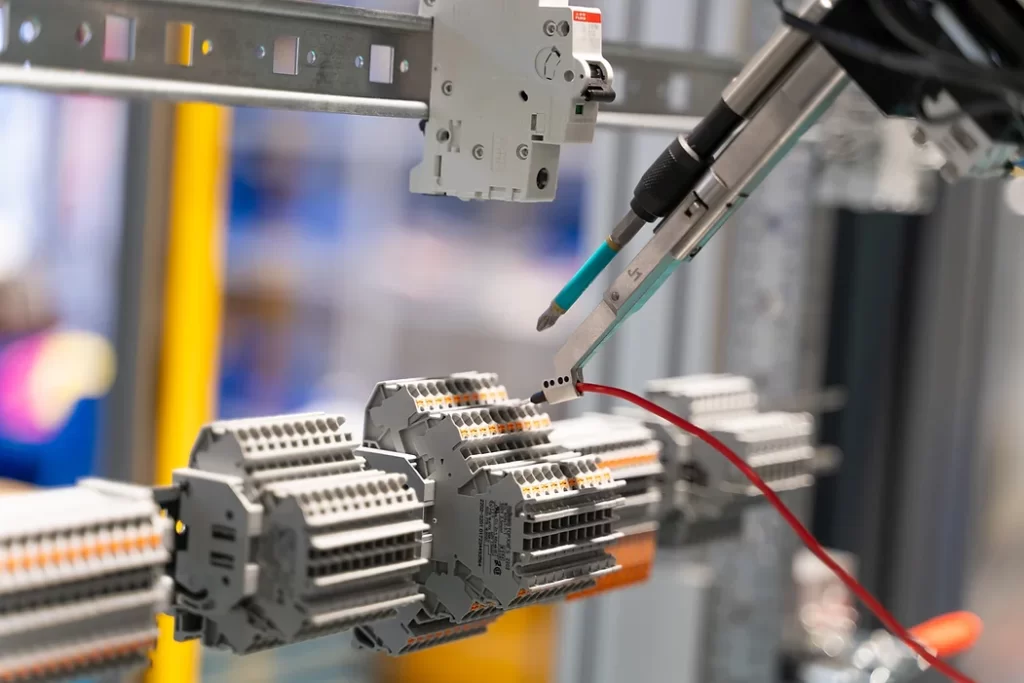

Using Process Simulate, WireBot can determine the optimal routing path while offline, reducing production time and conserving wiring materials. This proactive approach enhances reliability and minimizes production risks.”

Omer Einav, CEO of Polygon Technologies

The challenge: automating complex wiring tasks

Wire harness assembly is a vital yet highly complex part of manufacturing electrical control panels. Traditionally performed manually, this process is:

- Time-consuming and prone to human error

- Inefficient in material usage, leading to waste

- Challenging to scale for high-mix, low-volume production

Polygon saw an opportunity to optimize this process by introducing an intelligent robotic system that could automate wire routing, improve precision, and optimize production workflows. However, to ensure success, they needed a way to simulate, validate, and refine Wirebot’s operations before deployment—which led them to Siemens’ Process Simulate.

The solution: virtual commissioning with Process Simulate

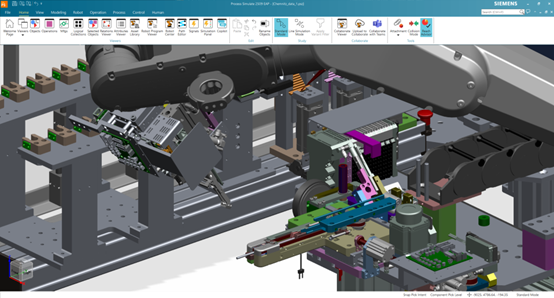

To bring Wirebot to life, Polygon turned to Siemens Process Simulate, a powerful digital manufacturing tool within the Tecnomatix® portfolio. This software allowed Polygon to:

✅ Optimize the wiring sequence to reduce cycle time and material usage

✅ Virtually validate and refine designs before production, eliminating costly errors

✅ Enhance real-time monitoring and control for improved quality assurance

✅ Reduce downtime when integrating new product variants

With virtual commissioning, Polygon could refine Wirebot’s operations in a digital environment before implementation, eliminating trial-and-error adjustments that typically slow down production.

Driving efficiency: The measurable impact

By leveraging Process Simulate, Polygon Technologies achieved significant improvements in production efficiency and reliability. The key results include:

These improvements translate into faster production cycles, lower costs, and higher-quality output.

- 70% reduction in onsite commissioning time

- 60% decrease in rework and error correction

- 70% less downtime when introducing new wiring variants

- Lower material waste, reducing costs on expensive resources like copper

Beyond speed and efficiency, Process Simulate provides an intelligent, data-driven approach to automation. With its digital twin capabilities, Polygon can simulate complex wiring scenarios, predict potential issues before production, and refine designs without disrupting operations.

Shaping the future of automated wiring

Following the success of Wirebot, Polygon continues to explore new ways to use Process Simulate. By embracing virtual commissioning and digital twin technology, Siemens and Polygon are redefining the future of robotic automation. Their commitment to innovation enables manufacturers to achieve new levels of precision, efficiency and scalability in their operations.