Maximize pharmaceutical plant efficiency with the power of Siemens Plant Simulation

In the fast-paced world of pharmaceutical manufacturing, optimizing plant design and operations is crucial for ensuring high-quality production and meeting regulatory standards. As the industry continues to evolve, adopting advanced technologies like simulation has become essential for designing and improving pharmaceutical plants. Utilizing simulation tools not only allows you to create more efficient and flexible plant layouts but also helps you predict and optimize resource consumption, material flow, and production line design before any physical construction takes place.

How simulation enhances pharmaceutical plant and layout design

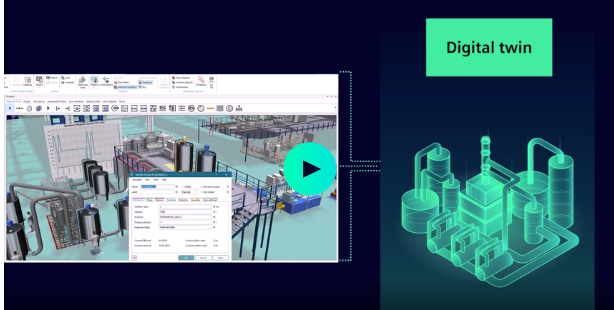

Tecnomatix Plant Simulation is a powerful tool that can bring a new level of precision to the design and operation of pharmaceutical plants. By creating a virtual model of the plant, engineers and designers can simulate various scenarios and identify inefficiencies early in the design process. This allows for the optimization of both the layout and workflow of the plant, ensuring maximum throughput and efficiency from day one.

One of the key advantages of simulation is the ability to visualize plant layouts in a virtual environment. This makes it easier to determine the most efficient flow of materials, personnel, and equipment. When these elements are correctly aligned, production runs more smoothly, reducing downtime and improving overall productivity. In the pharmaceutical industry, where precision is critical, having the ability to model every aspect of the plant before committing to physical construction can be a game changer.

Maximize throughput and efficiency in the pharmaceutical production with optimized plant layouts

A well-designed pharmaceutical plant is not only about meeting safety standards but also about ensuring that every step in the production process is optimized for efficiency. Material flow simulation tools like Siemens Plant Simulation allow plant designers to experiment with different configurations and layouts, identifying the best possible arrangement for equipment, workstations, and storage areas.

By simulating the movement of materials and products through the plant, designers can optimize the placement of machinery and reduce bottlenecks, which can often occur during the manufacturing process. This leads to increased throughput, better resource utilization, and fewer delays.

Improve intra-plant material flow and predict resource consumption early

In pharmaceutical manufacturing, material flow is key to ensuring a smooth and uninterrupted production process. Simulation enables plant designers to model the flow of materials within the plant, identifying any areas where flow disruptions may occur. Whether it’s raw materials, packaging, or finished products, understanding how materials move through the plant and optimizing the process before the plant is built is essential for maximizing efficiency.

Another benefit of simulation is its ability to predict resource consumption. By simulating various production scenarios, manufacturers can estimate the resources required for each phase of the process, including energy, labour, and raw materials. This predictive capability allows for better budgeting and resource allocation, ensuring that the plant operates within budget and does not overconsume critical resources.

Accelerate production line design with fewer errors

Designing production lines for pharmaceutical plants can be a complex and error-prone task, especially when it involves intricate machinery and strict regulatory requirements. Simulation offers a way to accelerate this process by allowing designers to experiment with different production line configurations virtually. By simulating the production process, manufacturers can identify design flaws and inefficiencies before physical implementation, reducing costly mistakes and delays.

With fewer errors during the design phase, production lines can be set up more quickly and efficiently. This accelerates the time-to-market for pharmaceutical products, ensuring that new medicines and treatments reach consumers as soon as possible.

Pharmaceutical simulation and optimization trial: a step forward

For pharmaceutical companies looking to harness the full potential of simulation, conducting a simulation and optimization trial can be a great first step. These trials allow you to test the effectiveness of different plant designs, production schedules, and material flows in a controlled, virtual environment before making any real-world investments.

This trial phase enables you to explore the impact of different variables on the efficiency of your plant and identify potential risks or bottlenecks early. By conducting simulations, you can make informed decisions about the most effective and cost-efficient ways to set up your pharmaceutical plant, improving both short-term results and long-term operational performance.

Simulation technology is revolutionizing the way pharmaceutical plants are designed and optimized. By enabling accurate modelling of plant layouts, material flows, and resource consumption, simulation tools offer manufacturers a chance to improve throughput, reduce errors, and optimize production processes before physical construction begins.

Whether you’re designing a new plant or optimizing an existing one, leveraging the power of simulation can help you meet the evolving demands of the pharmaceutical industry while ensuring compliance, safety, and efficiency. By integrating simulation into the planning phase, you not only accelerate production line design but also pave the way for a more efficient, cost-effective, and scalable manufacturing operation. https://plm.sw.siemens.com/de-DE/tecnomatix/plant-simulation-software/

Join us at the Hannover Fair 2025 to learn more about how our advanced tools can help you model, simulate, analyze, visualize, and optimize pharmaceutical manufacturing processes, driving efficiency and innovation at every stage of production. Don’t miss the opportunity to see how we’re shaping the future of pharmaceutical manufacturing with cutting-edge solutions!