Products

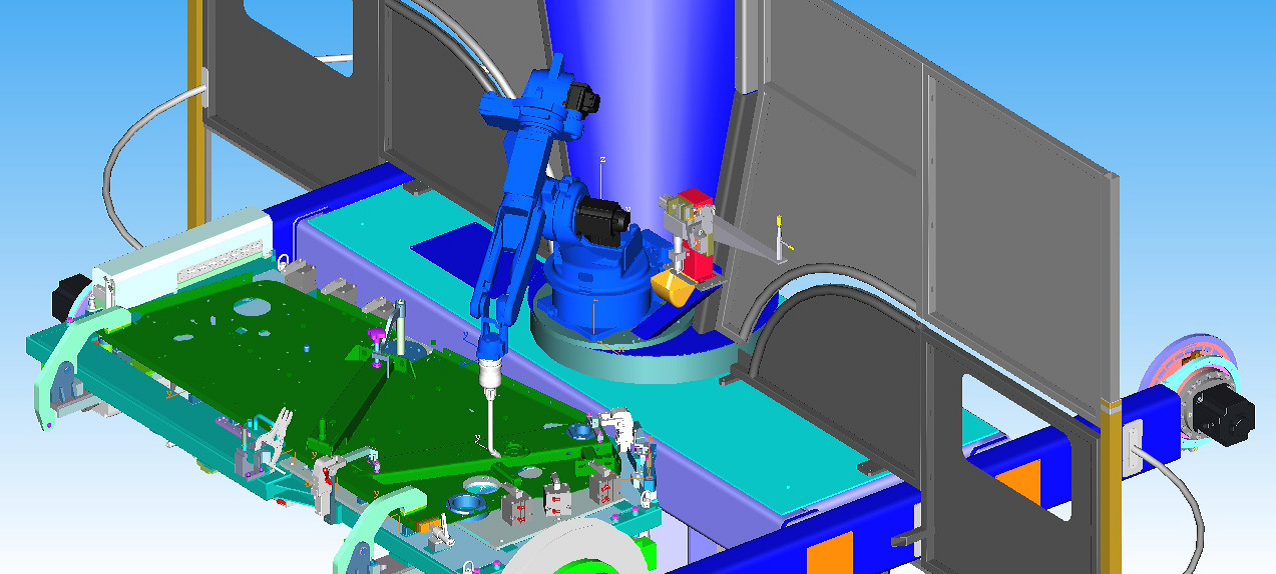

John Deere Reduces Robot Programming Time with RobotExpert

In this new case study you’ll learn how long-time Siemens’ customer, John Deere de Arc-les-Gray, a subsidiary of John Deere, added offline robot programming using RobotExpert to extend its digital factory and, as a result, shortened factory lead times. Here are a few highlights from the article:

- John Deere implemented offline robot programming and reduced programming time from one week to two to three days.

- Production downtime has been dramatically reduced by a factor of three.

- An employee, fresh out of welding school, was successful in modeling a robot installation and creating a part program easily by taking advantage of Siemens’ online tutorials and demo version of RobotExpert.

- And, last, you’ll learn how John Deere has optimized design and manufacturing processes with concurrent engineering.

Read the complete case study, “John Deere”

Did you know you can give RobotExpert a free, 30-day trial run at no obligation? All you have to do is register and we’ll send you the software today. Give it a try!