Investing in manufacturing simulation

Watch this video featuring Carlos Ortega, Digital Manufacturing Consultant from Engineering USA, to learn how you can avoid the major challenges of deploying a discrete event simulation initiative. We caught up with Carlos during Realize LIVE to talk about his expertise in teaching manufacturers how to avoid common mistakes.

Video Transcript:

I’m Carlos Ortega, Digital Manufacturing / Simulation Consultant, Engineering USA, I am responsible for the deployment of projects. I’m also in pre-sales, training, and all over the place within simulation. I have been lucky enough to be a part of this environment for 13 years. I enjoy my work a lot. You can see that!

This is my first time at Realize LIVE. I’m impressed, of course! I mean there are a lot of people here with a lot of knowledge and companies here searching for knowledge now that we are in this Industry 4.0 environment with new technologies, software, and new things that are coming out. It has been amazing in a sense. I have enjoyed this event a lot. Just looking at all the interactions with people, companies, coming together and trying to learn more and more, and going to the sessions. The feedback that we’ve had from all the sessions has been amazing. In a word, I am just impressed.

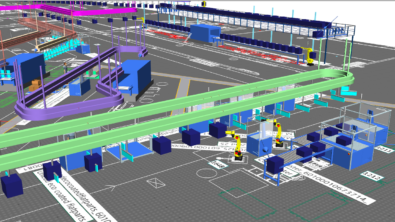

In the 13 years I have been doing this, it may sound like a lot but it’s not, I have come across the same challenge through that time. We have a disconnection between our design world and our manufacturing world. That is still there! That is still the challenge, how we get product information going all the way from manufacturing, shop floor, and execution. So, that is still the challenge. People still come across us looking for that digital thread. And, we have it! The amazing part is we have the samples, we have the tangibles about the digital thread and the benefits of it. People are still looking for that. Which is impressive. So, yes, the challenges and objectives are still there. The same type of objectives, amazingly enough. We are there for that challenge. We are always striving for that.

For this Plant Simulation presentation, I took a different approach. I have always gone in the direction of being more technical or showing successful projects or success stories. For this one, I am going a step before that. We are trying to help people understand what goes before going into a simulation initiative. Which I have seen through all this time is a challenge. Just getting your foot in the door and being successful after that.

One of the highlights, from my experience, most of the simulation initiatives can go wrong when you start or when you are deploying them. What I am trying to show is how we can avoid these common mistakes. We go into that and how we can plan for that the right way, so we have a successful simulation initiative. And, of course, all of this is tied together with Industry 4.0 – that is a current thing. How can we make our simulation initiative successful from the get go, instead of fighting through it once we start?

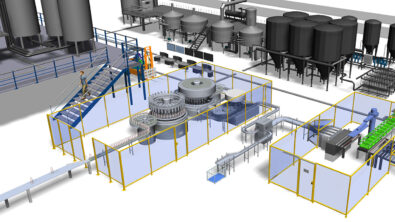

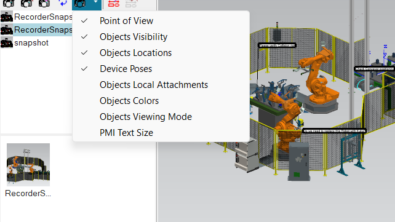

Follow this link to learn more about Tecnomatix Plant Simulation.