From Static Plans to Dynamic Production: How Brose Drives Efficiency with Plant Simulation [video]

As a premium automotive supplier, Brose is at the forefront of innovation, specializing in intricate components like seat structures, door modules, and actuators. But even with cutting-edge products, manufacturing comes with its own set of complex challenges. In a world where production is anything but static, relying on traditional, static calculations can often lead to bottlenecks and inefficiencies.

This is where Siemens Plant Simulation became a game-changer for Brose. By creating digital twins of their operations, they could move beyond static assumptions, connecting disparate planning silos and visualizing the entire production flow. This allowed them to proactively identify bottlenecks, optimize buffer sizes, and virtually test improvements before implementing them on the shop floor, ultimately driving significant efficiency gains.

The Challenge: When Static Calculations Just Don’t Cut It

Many manufacturers, including those as sophisticated as Brose, have historically relied on static calculations for production planning. While these methods provide a baseline, they struggle to account for the dynamic, ever-changing nature of a real production environment. Think about it: welding, logistics, and assembly often operate in isolated planning “silos,” making it incredibly difficult to see how changes in one area impact the entire value stream. This can lead to:

- Unforeseen bottlenecks: A seemingly small change can disrupt the entire flow.

- Suboptimal buffer sizes: Either too much inventory tying up capital, or too little leading to stoppages.

- Difficulty in visualizing impact: Management struggles to grasp the true consequences of proposed changes.

The Solution: Connecting the Dots with Siemens Plant Simulation

This is where Siemens Plant Simulation steps in as a powerful ally. Brose utilizes this advanced digital twin technology to create a comprehensive, dynamic model of their entire production process. It’s like having a crystal ball for your factory floor!

Here’s how Plant Simulation transforms their approach:

- Connecting Isolated Silos: Instead of treating welding, logistics, and assembly as separate entities, Plant Simulation brings them all together. This allows Brose to see the true interconnectedness of their operations and understand how each part influences the whole.

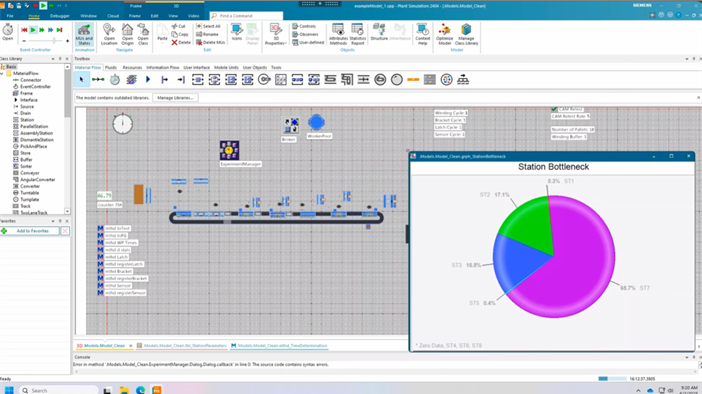

- Optimizing Bottlenecks and Buffer Sizes: By simulating various scenarios, Brose can identify potential bottlenecks before they occur on the shop floor. This enables them to optimize processes, minimize buffer sizes, and ensure a smoother, more efficient flow.

- A Bird’s Eye View for Management: Plant Simulation provides a visual, intuitive representation of the assembly line and value streams. Management can see the impact of proposed changes – like adding another pallet or shuttle – in a virtual environment, making informed decisions easier.

- Trial Before Implementation: One of the biggest advantages is the ability to “trial out” different aspects and changes virtually. This means Brose can test new layouts, process modifications, or resource allocations without disrupting actual production, saving significant time and cost.

Real-World Impact: Solving a Palletized Line Bottleneck

A perfect example of Plant Simulation in action involved a palletized line at Brose. An automated station’s cycle time grew beyond its plan, becoming a critical bottleneck. By inputting detailed data – process times, operator cycle times, and relationships between different operations – into Plant Simulation, Brose could:

- Pinpoint the exact cause: The simulation clearly showed the impact of the station’s extended cycle time.

- Visualize the consequences: The plant team could see how this bottleneck affected the entire line.

- Explore optimization strategies: Brose could then use the simulation to test different approaches to address that cycle time, such as reallocating tasks or adjusting machine parameters, ultimately optimizing the flow.

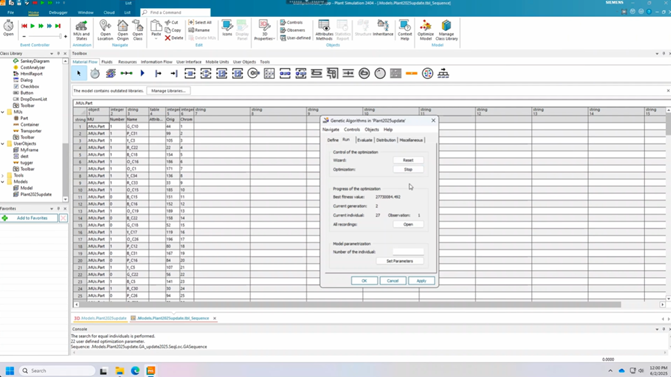

Beyond the Basics: Leveraging Genetic Algorithms for Advanced Optimization

The power of Plant Simulation extends even further. Brose uses advanced features like genetic algorithms to tackle complex optimization problems. For instance, when optimizing routes for drop-off locations, they can:

- Hypothetically test countless routes: The algorithm explores every possible opportunity for drop-offs.

- Evolve based on KPIs: By coding in key performance indicators, the algorithm is forced to evolve towards the most efficient scenario, ensuring optimal routes and resource utilization.

The Bottom Line: Enhanced Efficiency and Virtual Problem Solving

The biggest impact of implementing Plant Simulation at Brose has been a dramatic increase in efficiency. It provides visibility into both current operations and future planning, allowing them to,

- Identify gaps early: Proactively address potential issues before they become costly problems.

- Avoid future costs: Prevent expensive rework or production delays downstream.

- Understand pain points virtually: Gain deep insights into operational challenges without impacting physical production.

“With Plant Stimulation, we can identify those gaps early on and help address them to really avoid that future cost that we would end up taking on downstream when we actually hit production. And then we can understand those pain points virtually. So if you have the right mindset, the amount of problems that you can solve are really limitless.“

Ryan Schoettle,

Digitalization Industrial Engineer,

Brose