Discover what’s new in Tecnomatix 2502 (February 2025)

Digitalization for advanced manufacturing.

The Tecnomatix® portfolio delivers advanced digital manufacturing software to empower businesses across diverse industries and sizes. Tecnomatix 2502 launched recently with several exciting new advancements in the areas of cloud computing, AI-driven technologies, Teamcenter connectivity, UI updates, collaboration, augmented reality, robotics simulation, offline programming, virtual commissioning, human simulation and virtual reality.

In this blog, we explore how the Siemens Xcelerator portfolio, including Tecnomatix digital manufacturing software, helps companies minimize manufacturing risks and improve their production operations. Siemens Xcelerator is an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale.

Tecnomatix software helps companies minimize manufacturing risks and improve their production operations. We are excited to bring these latest enhancements to you!

You don’t have Tecnomatix software?

General enhancements

See the highlights from Tecnomatix 2502:

Generative artificial intelligence (AI) for smarter simulations

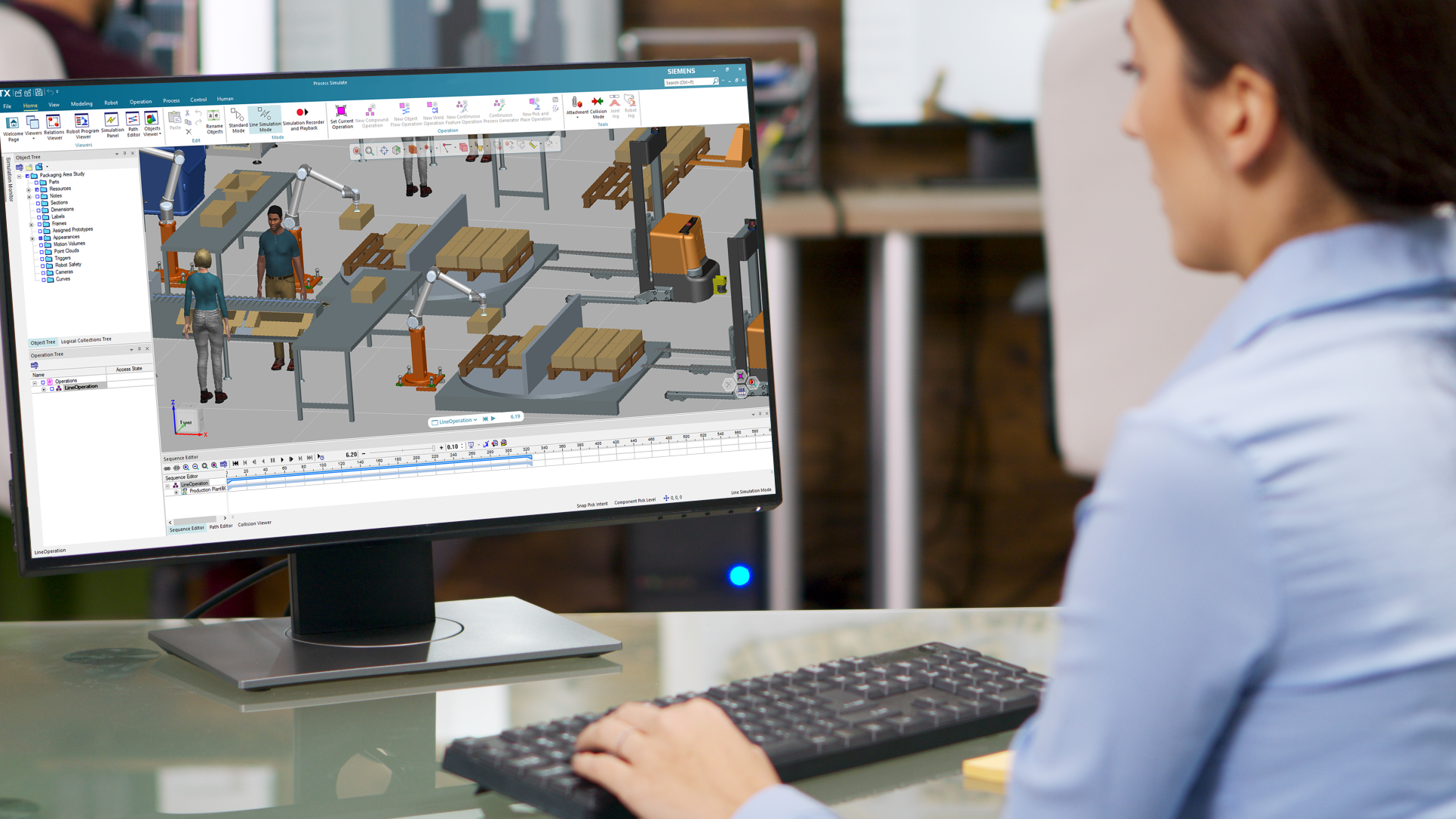

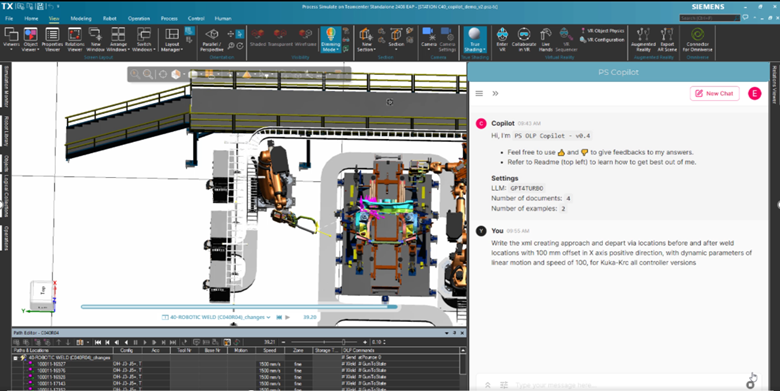

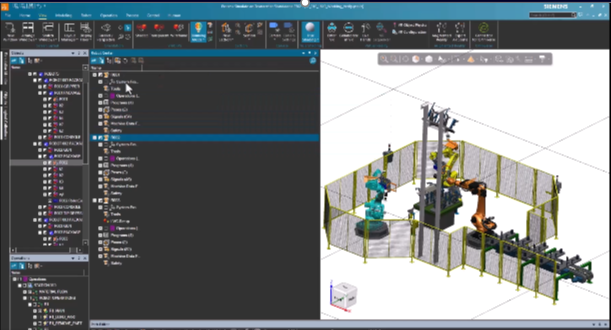

Process Simulate X, cloud-enabled digital manufacturing software for planning, simulating, and validating human tasks, robotics processes, and automation in a 3D environment was released in 2408. In 2502, explore new benefits of the cloud-based deployment software with AI-powered features to give manufacturers the flexibility and security they need to scale their operations efficiently.

Process Simulate X introduces Process Simulate Study and Simulation Query, leveraging Generative AI to streamline troubleshooting and optimization. These enhancements provide instant insights based on real simulation data, eliminating the need for manual searches and time-consuming analysis.

The Simulation Monitor offers real-time visibility into robotic operations, tracking execution status, performance metrics, and safety parameters. Meanwhile, the Simulation Log captures every event and error with precise timestamps, making it easier to diagnose issues. Process Simulate Study understands robot signals, motion commands, and object interactions, helping engineers optimize their setups. Simulation Query allows users to retrieve relevant insights instantly, providing contextual recommendations without the need to dig through logs.

By integrating AI in Process Simulate X, these enhancements significantly reduce troubleshooting time, improve productivity, and enhance process optimization. Access quick, accurate, and traceable insights, allowing you to make data-driven decisions with confidence.

Process Simulate on Teamcenter

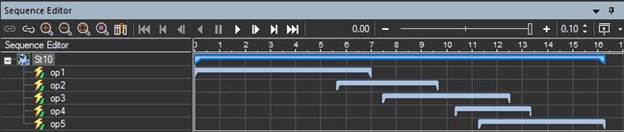

Edit operation start time

Explore new integration enhancements for Process Simulate on Teamcenter, starting with editing operation start time. To further ease authoring in Process Simulate on Teamcenter, Tecnomatix 2502 introduces the flexibility to set operation start times, allowing for a more optimized workflow. Operations that are not linked can be positioned along the timeline as needed, either by dragging the operation bar in the Sequence Editor or adjusting the Operation Properties dialog. This enhancement provides a clearer representation of overlapping tasks and wait times, improving simulation accuracy and process visualization.

Once an operation is linked to a previous one, its start time is automatically calculated based on the end time of the preceding task, ensuring logical sequencing while maintaining flexibility where needed.

Study Manager – support variant configuration

The new Study Manager enhancement in Process Simulate on Teamcenter allows you to apply variant rules before loading studies, ensuring that only the relevant data is included. Select a specific variant rule and instantly filter out conflicting data. This streamlined approach extends beyond study loading, supporting commands like Manufacturing Search and Assign Data from Teamcenter, ensuring that all retrieved information aligns with the selected variant.

By integrating seamlessly with Product Configurator, Study Manager provides a unified environment, improving accuracy and efficiency. With this enhancement, you can easily switch between configurations, refine data specific to each variant, and ensure consistency across simulations. This not only saves time but also enhances decision-making by providing a clear and structured way to manage variant-specific manufacturing data.

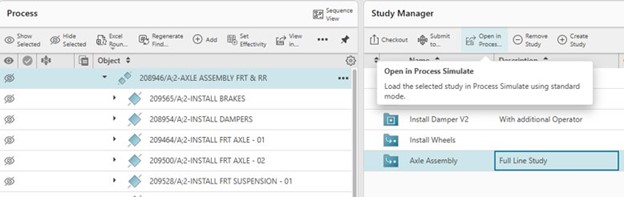

Open Process Simulate from the Easy Plan Study Manager

With the latest updates in Tecnomatix 2502, you can easily load and manage data between Easy Plan and Process Simulate. Now, from the Easy Plan Process Planning Page, you can directly open Process Simulate via the Study Manager. This integration enables you to see a study list for a work package, add or remove studies, and load them into Process Simulate for seamless data transfer and simulation preparation.

This enhancement drastically reduces the complexity of transferring data between platforms, saving time and improving process accuracy. By loading process scope data directly from Easy Plan into Process Simulate, you can achieve a more connected workflow.

Support Process-Resource Data for Line Balancing

Process Simulate on Teamcenter now offers enhanced Process-Resource Data support, improving how you can allocate, sequence, and manage operations within manufacturing processes.

The Operation Tree now provides a hierarchical view, displaying each machine and operator with their assigned operations listed below. Easily move, add, or remove operations under specific resources, improving flexibility in workstation planning.

using the Sequence Editor, all operations within a station appear in a single, flat list, regardless of which resource executes them. A dedicated Process Resource column makes it easy to track and adjust assignments while maintaining a logical sequence.

The Relation Viewer further simplifies process management by clearly displaying the connections between operations and their assigned resources. When using Easy Plan in Teamcenter, managing tasks across multiple stations is now correctly loaded into Process Simulate, ensuring a more seamless and accurate planning process.

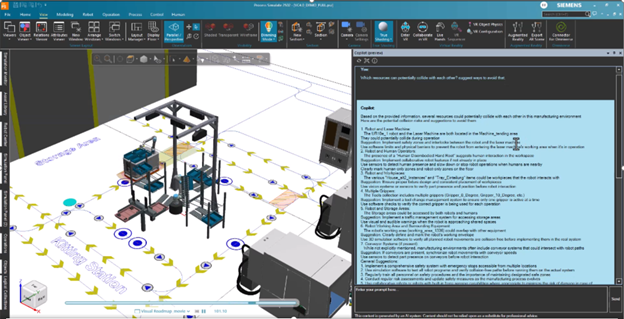

Process Simulate Collaborate

Tecnomatix Process Simulate Collaborate is a cloud-based, 3D collaboration solution to visualize, review and analyze Process Simulate studies in a collaborative environment. The 3D simulation collaboration tool helps save time and effort by extending Process Simulate studies into the cloud, providing internal and external stakeholders access to the richness of your Process Simulate studies, saving time and effort.

The Tecnomatix 2502 release introduces several innovative capabilities in Process Simulate Collaborate that enhance collaboration and efficiency in engineering workflows.

Key features include:

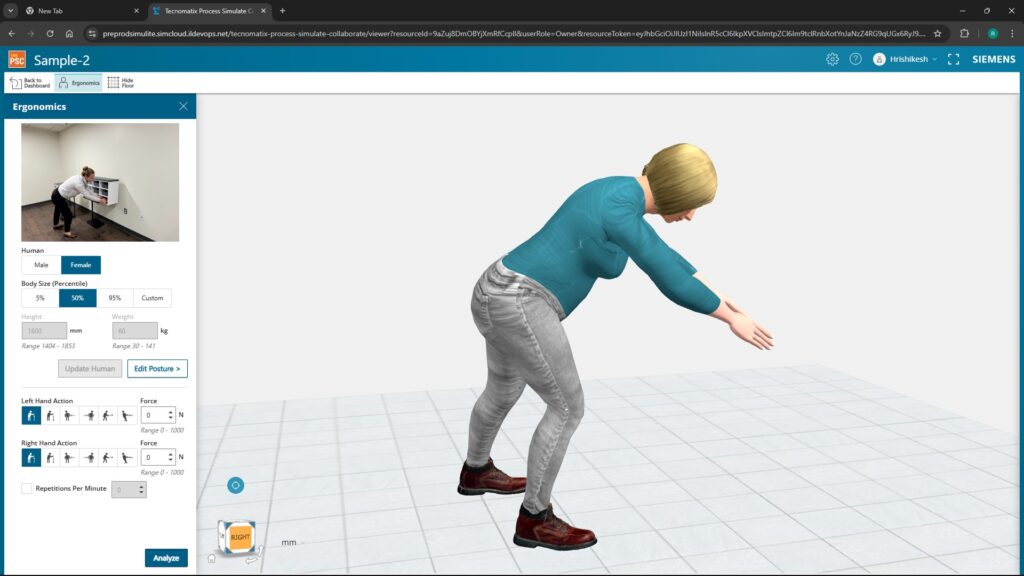

AI-driven ergonomics on the cloud

Process Simulate Collaborate introduces an AI-powered ergonomic analysis tool, transforming how companies assess and improve workplace safety. With the ability to convert 2D images into 3D digital human models, users can now upload pictures of tasks or postures directly into the system for automated ergonomic evaluation. The AI-driven solution analyzes human performance, providing risk mitigation recommendations and task optimization insights without the need for complex motion capture or manual assessments.

Leveraging AI-powered ergonomics in Process Simulate Collaborate, you can achieve faster, data-driven decision-making, improving both worker safety and operational efficiency. Proactively identify ergonomic risks, enhance workplace conditions, and optimize human tasks with minimal effort. This innovative approach simplifies ergonomic assessments while making them more accurate, accessible, and effective than ever before.

Collaborate Viewer for Process Simulate X

The Collaborate Viewer for Process Simulate X provides direct access to Process Simulate Collaborate, allowing you to effortlessly share, review, and refine simulation studies without switching platforms or logging in separately.

Use the Collaborate Viewer available in Tecnomatix 2502to load study data and notes, ensuring teams have full visibility into shared feedback. Studies can be shared instantly with stakeholders, making it easy to coordinate across teams. The integration also enables real-time collaboration, allowing multiple users to work on the same study simultaneously. To further streamline communication, set up Microsoft Teams meetings with embedded study links or quickly copy and share unique study access links.

Whether accessing, updating, or managing studies in Standard or Line Simulation Mode, the Collaborate Viewer simplifies how teams interact with simulation data, making it faster and more intuitive.

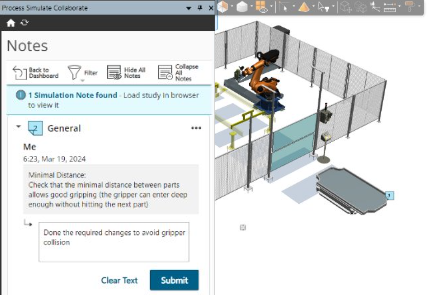

Load Collaborate Notes

With the new Load Collaborate Notes feature available in Tecnomatix 2502 for Process Simulate X, you can easily collaborate and document simulation changes, streamlining the review process and ensuring that all input is addressed efficiently.

This exclusive enhancement allows you to load Collaborate Notes directly in the Viewer, visualize their locations in the scene, and interact with them in real-time. Focus on specific notes, reply to feedback, resolve issues, and delete notes once addressed, ensuring that the feedback loop is complete.

Embedding collaboration directly into Process Simulate X eliminates the need to track external comments manually. You can act on reviewer input instantly, reducing miscommunication and speeding up the validation process. Using Load Collaborate Notes, teams can ensure that every piece of feedback is visible and actionable — leading to more accurate and optimized simulations.

Robotics

Process Simulate Robotics helps you program and validate your robotic processes in a dynamic 3D environment. It includes robotics applications for spot welding, metal processing, drilling and riveting, surface treatment, and assembly.

The following new capabilities were released in Tecnomatix 2502.

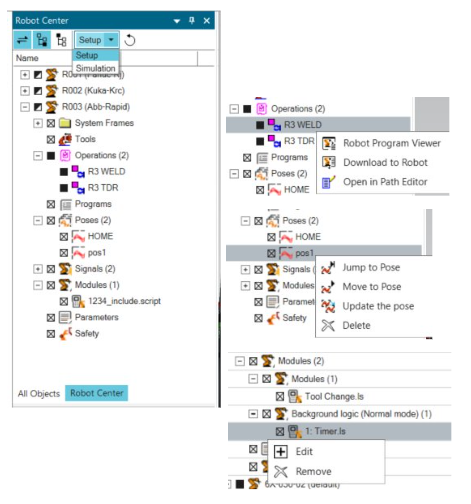

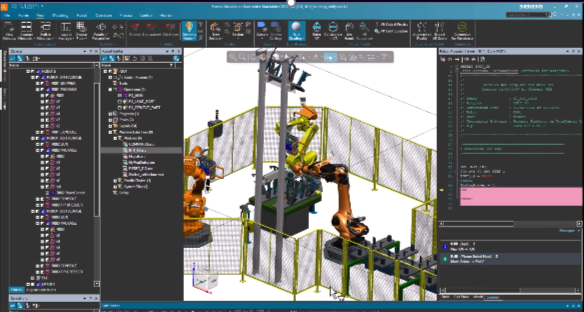

Robot center

In Tecnomatix 2502, the latest enhancements in Process Simulate Robot Center improve usability, making it easier to access and manage robot-related settings while reducing the learning curve. This new interface allows you to easily navigate through various robotic commands associated with each robot in their study and significantly reduces the learning curve for inexperienced users. The Robot Center supports all controllers, providing tailored setup options, while offering features like filtering by station or robot. These enhancements further unify the interface, allowing for efficient interaction with robot properties and settings in one convenient location.

Controllers view

The new Controllers view optimizes the controller and motion planner settings. A toggle allows you to switch to a streamlined table view, replacing the legacy controller settings dialog. It organizes information with improved column visibility based on the motion planner in use, supports multi-edit for quick adjustments, and uses color coding to highlight issues — orange for uninitialized RCS/VRC connections and italic red for incorrect entries. Verify connections or terminate RCS sessions with dedicated buttons, simplifying controller management.

Robot Modules now support motion blocks and debugging directly in the Robot Program Viewer. Modules are converted on the fly during simulation, ensuring seamless execution. For performance-sensitive cases, manual conversion can be done upfront for individual or multiple modules. Successfully converted modules appear with a green icon, allowing debugging with breakpoints, call stack tracking, and step-through execution. Failed conversions are marked with a red X and will not support the new features. Since conversion results are not stored between sessions, modules must be reconverted upon reopening a study.

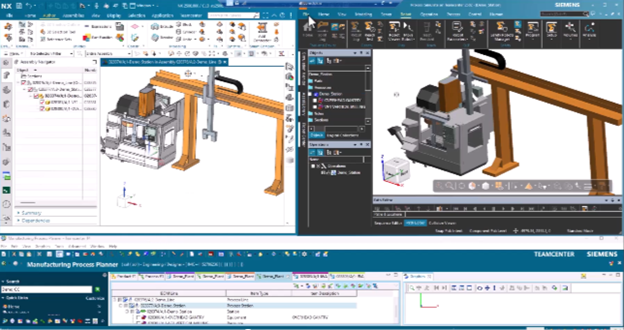

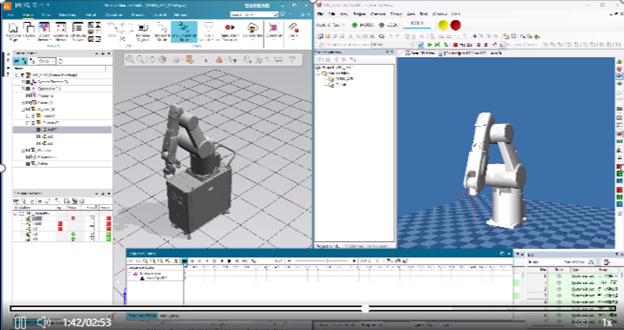

Exchange of kinematics between Process Simulate and NX

Create a seamless process for extracting and consuming kinematic data with the exchange of kinematics natively between NX and Process Simulate. With this single source of truth, you can ensure synchronized geometry and kinematic models.

Starting with NX 2506 and Process Simulate 2502, you can activate an option that enables automatic synchronization. When models are saved in either system, the kinematic dataset is embedded and recognized across both, eliminating manual conversion steps. Process Simulate detects NX-native JT (.jt) files and converts them automatically, ensuring kinematics remain intact without additional setup.

This streamlined exchange enhances efficiency, reduces errors, and ensures consistency across Siemens platforms. Whether working in Teamcenter, eMServer, or other CAD environments, the kinematic data remains synchronized, reducing complexity and improving workflow integration.

Cable Bundles

The introduction of Cable Bundles enhances the accuracy of complex cable package simulations by allowing you to define and manage bundled cables within the Cable Groups command.

Cable Bundles improve realism by constraining multiple cables to move together at specific points, mimicking real-world attachments like zip ties. This feature enables early detection of issues such as collisions, contact, and twists, even in complex robotic dress packages. Configure bundles with multiple cables, define attachment points using the Distance parameter, and adjust orientation and spacing with the Frame selection parameter.

These enhancements streamline robotic cable management, reducing design iterations and improving overall system reliability.

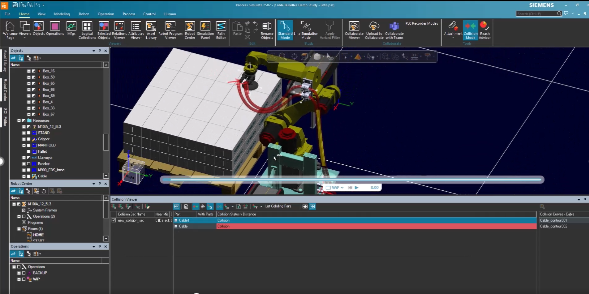

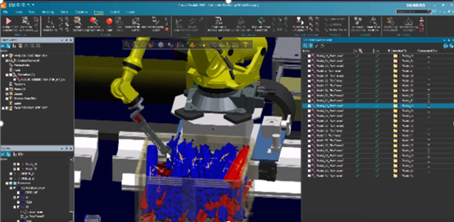

Bin picking analysis

In Tecnomatix 2502, explore the Bin Picking Analysis Tools in Process Simulate Robotics, providing early validation to ensure smooth and reliable robotic operations before deployment. This enhancement helps ensure efficient bin picking, which is critical for automated production.

The Bin Picking Operation command simplifies the creation of bin-picking sequences using an intuitive interface, making setup faster and more efficient. Analyze reachability and collision risks, ensuring robots can successfully access and retrieve parts without interference. Simulation capabilities further enhance troubleshooting by illustrating dynamic challenges such as on-the-move collisions and singularities. By integrating these tools, you can test bin picking processes early, refine robotic motions and prevent late-stage issues that could disrupt production.

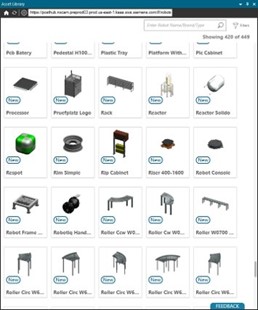

Asset library

In the Tecnomatix 2502 release, the Asset Library, previously known as Robot Library, has been expanded, offering a wealth of added resources for creating compelling 3D studies and layouts. The updated library now includes not only hundreds of robot models but also a wide range of CAD elements such as robot peripherals, conveyors, cabinets, machines, and more. This extension provides you with an intuitive drag-and-drop functionality, making it easier to quickly draft designs, create concepts, and assist with conceptual design workflows.

Virtual commissioning

Process Simulate Commissioning helps you to run the PLC code that controls the station to validate robot motion, robot logic and other mechatronic components such as clamps, conveyors, and the entire process sequence. Virtual commissioning works with real PLCs (hardware in the loop, HiL) or virtual PLCs (software in the loop, SiL) and with the Process Simulate cyclic event evaluator/emulation (CEE) internal evaluation tool.

The following capability was released in Tecnomatix 2502.

Denso VRC

The latest enhancement in Process Simulate Virtual Commissioning introduces a new VRC Server for Denso Robots, providing a seamless connection to WinCaps III. This integration allows for direct exchange of positions, signal values (IO), and messages, improving simulation accuracy while reducing setup time.

Using direct program transfer between Process Simulate and WinCaps III, you can easily download and upload robot programs, ensuring a smoother workflow and more precise virtual commissioning. By leveraging WinCaps simulation capabilities within Process Simulate, you gain a more reliable and efficient way to test and validate Denso robot operations before deployment.

Human simulation and virtual reality

Process Simulate Human helps you to eliminate any risk to operators with walk path analysis, reachability tests, vision analysis and ergonomics assessments.

Process Simulate Virtual Reality delivers an immersive environment for better engineering reviews, staff training and realistic process validation.

The following new capabilities were released in Tecnomatix 2502.

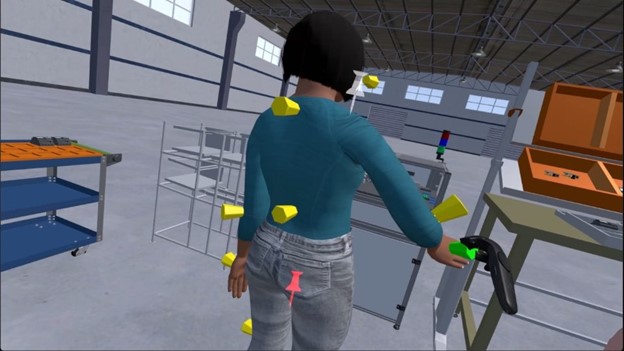

Immersive posturing

Process Simulate Virtual Reality delivers a responsive immersive experience with major performance and rendering improvements. A new rendering pipeline dramatically increases frame rates, making navigation of complex scenes seamless and reducing lag. Interact with simulations more efficiently, improving usability and decision-making in virtual environments.

Additionally, Kineo technology enhances cable simulation, allowing you to convert a single cable and optionally connect end fittings for realistic interactions. This feature enables human operators to grasp and move cables within the VR space, improving visualization and accuracy for assembly and ergonomic studies. Using these upgrades, VR simulations feel more lifelike and intuitive, empowering teams to optimize manufacturing processes with greater confidence.

Vive body tracking

The latest update to Tecnomatix 2502 delivers improved Vive Body Tracking, providing smoother and more realistic human motion tracking. Movements now more accurately reflect real-world actions, resulting in higher-fidelity simulations when recorded and saved in Process Simulate.

Using these enhancements, fully immerse in VR, embody a digital figure, and act out real-world scenarios using Vive Trackers. These recorded motions can then be analyzed for process optimization, ergonomic studies, and workflow improvements. By refining how human movements are represented, this update ensures greater accuracy, making VR-based simulations more reliable and flexible.

Spawn locations

Immersive virtual reality (VR) sessions in Process Simulate are now more flexible with the introduction of customizable spawn locations. Specify exactly where to enter a VR scene at the start of an immersive session. This feature, accessible in the VR Configuration dialog, allows you to create one or more spawn locations, ensuring that you can begin at the most relevant position for your workflow. In VR Collaboration, multiple spawn locations can be assigned, enabling each participant to start from a unique position, improving coordination and efficiency. By gaining full control over the entry point, this enhancement makes VR simulations more intuitive and tailored to specific tasks, streamlining collaboration, and optimizing the immersive experience.

—–

These are just highlights of the advancements delivered with the latest Tecnomatix release. For complete details on the new features of Tecnomatix 2502 and its supporting releases, please refer to the release notes and new features presentations offered with the software download.

Do not forget to join the Tecnomatix public community and to explore our website for even more exciting developments in digital manufacturing.

Yours in digital manufacturing,

Kelly

(on behalf of the entire Tecnomatix product team)

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)