What’s New in Teamcenter Quality 6.2

Your Quality Management Solution

We are excited to announce that the latest version of Siemens quality management software – Teamcenter Quality 6.2 — has been released!

Teamcenter Quality, which is a part of Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps you support all of the quality-relevant processes required in production.

Benefits of quality management solutions

- Apply FMEA best practices to detect possible failures early in the development stages

- Keep all your relevant information in standardized FMEA projects

- Optimize quality planning with process driven inspection planning

- Strengthen alignment between quality and manufacturing process data

- Manage the root cause analysis tools by using the problem-solving process

- Manage a single source for all your quality data

Latest features

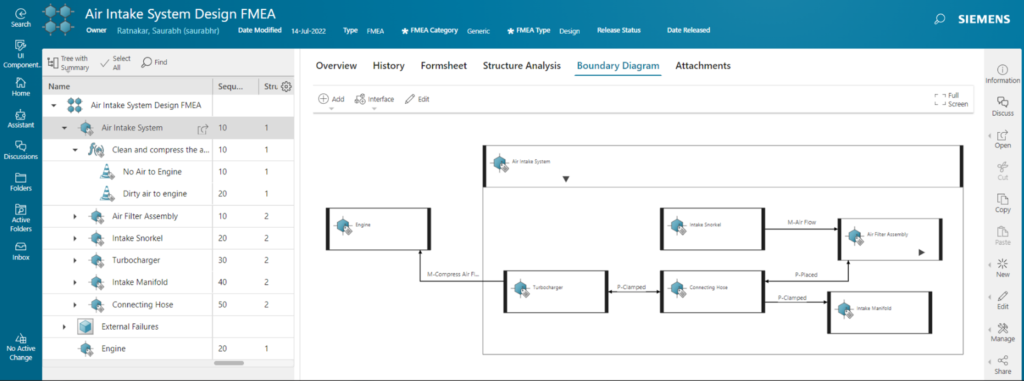

- Create boundary diagrams within design FMEA to reuse engineering data for quality analysis

- Improve usability for searching and standardized form sheets in the FMEA module

- Optimize alignment between FMEA and control plan to collect all relevant information

- Transfer of the BOP operation from the FMEA to the control plan

- Leverage easy-to-use drag and drop function for root cause analysis tools

- Use enhanced quality master data for quality checklists and quality actions

Following Teamcenter Quality modules were enhanced:

- Failure Mode and Effects Analysis (FMEA)

- Control and Inspection Planning, Quality Project Management

- Problem Solving

- Quality Issue Management and Quality Action Management

Recognize possible failures early in development stages with FMEA

FMEA is a methodology that allows companies to assess risks associated with possible product failure. The Teamcenter Quality FMEA module helps you support preventive defect avoidance by allowing you to evaluate the effects caused by potential problems early in the planning phase. The FMEA module supports several standards and guidelines.

The quality planning with Teamcenter Quality is further improved with the FMEA release 6.2. The new important element is the FMEA boundary diagram, or block diagram, a visual representation of the system that displays what is included or not in the FMEA to clearly describe the target of the FMEA breakdown. The FMEA boundary diagram should be used as an analysis tool for the preparation of system or design FMEA.

Experience the benefits of closed-loop quality and start your digital journey

for Quality Management with Siemens today!

Would you like to get a general overview of our offerings of quality management software?

Take a few minutes to look into our new Teamcenter Quality 6.2 fact sheet, or learn how to experience the benefits of closed-loop quality for best-in-class products with our videos experience.

Are you interested in more details on our quality management software solution components?

Take a deep dive into five of them by reading these fact sheets:

- Teamcenter Quality – Problem Solving

- Teamcenter Quality – Control and Inspection Planning

- Teamcenter Quality – Failure Mode and Effects Analysis

- Teamcenter Quality Project Management

- Teamcenter Quality Action Management

Find out more about Teamcenter Quality on our website.

Learn more about our approach to quality management software.