What’s new in Product Cost Management?

With the enhancements in Teamcenter Product Cost Management version 9.2, we support product and manufacturing cost reduction initiatives. You can discover unknown savings within a group of products highlighting the outliers. Then, predict costs with artificial intelligence which will simplify future decisions for quick price calculation and adjustments. The optimization of carbon emissions and product cost can be analyzed together and at every step of the lifecycle. These updates support you in achieving your climate targets and helps compete profitably in a rapidly changing business environment.

Extended portfolio with top-down costing using NLPP

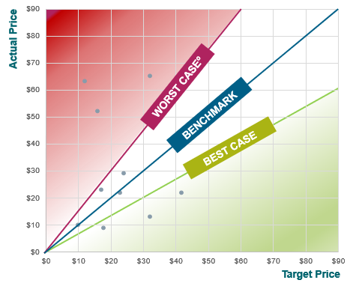

Traditional cost and value analysis have mainly been based on bottom-up methods. To accelerate handling large part portfolios, Siemens added the top-down Non-Linear Performance Pricing (NLPP) method to its solution portfolio. In contrast to bottom-up calculations, which focus on the highly precise analysis of individual parts, the NLPP method developed by the Swiss company Saphirion AG examines part families. NLPP can predict the cost and price of any part, machine, or tool. The method uses part properties, quantities, and actual prices of existing parts to determine valid and precise target price formulas automatically. Such target price formulas precisely describe how different part properties impact part costs or prices. Further, NLPP Hot-Spot Analysis calculates meaningful benchmarks that give a target corridor with upper and lower bounds for part costs or prices. NLPP Hot-Spot Analysis shows potential savings by identifying similar parts or assessing variants’ price differences. For further details you can view the on-demand webinar.

Predictive costing with Teamcenter Product Cost Management

The new release provides the possibility to reuse an intelligence created with the NLPP Hot Spot Analysis by easily integrating a NLPP target price formula into Teamcenter Product Cost Management. This target price formula can be used to predict the prices of parts, components, and even systems. You can use this predictive costing approach for many use cases to accelerate your calculation process. For example, after importing a large assembly into Teamcenter Product Cost Management you can instantly predict the prices for all “B” and “C” parts so that you can focus on the “A” parts. In addition, you can challenge your own bottom-up calculations by comparing the result with the price prediction from NLPP. In summary, you can use NLPP to easily train target price formulas for any commodity and integrate this formula into Teamcenter Product Cost Management to enable predictive costing capabilities. NLPP is a quick approach to predict prices which can be used to speed up the calculation process of cost engineers but can also become a suitable alternative for occasional users with missing cost engineering expertise.

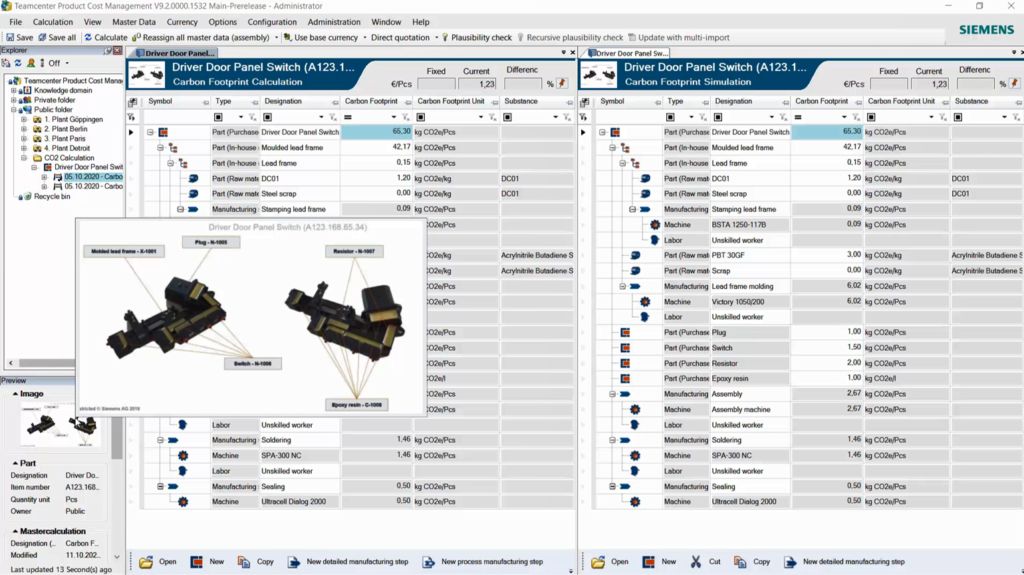

Achieve climate targets by understanding and analyzing a product’s carbon footprint

Environmental responsibility is an important topic since many companies all over the world follow strong climate targets. Especially in automotive, new car programs have the goal of getting as close to carbon neutrality as possible. For this purpose, we have extended the Teamcenter Product Cost Management solution by a carbon footprint calculator. This provides you the capability to run cost and carbon footprint calculations at one glance supporting you in:

- Understanding your product’s carbon footprint today by calculating the respective carbon emission drivers in your product

- For example: material substance, energy during production, transportation, etc.

- Analyzing the drivers and run what-if simulations with the goal to identify measures on how to reduce your product’s carbon footprint

- Executing the measures to achieve your product’s climate targets

Extended lifetime calculation to support multi-year calculations

In order to achieve more sophisticated use cases in the cost calculation of a product’s lifetime, we need to support multi-year bill of materials, bill of processes, capital assets, and cost calculation assumptions. With this release, we incorporated the following calculation assumptions into your product’s lifetime:

- Future material price fluctuations (e.g. electronic parts as chips or resistors can decrease in price significantly within years)

- Project-specific exchange rates (negotiated project-specific exchange rates with your customers or suppliers over the product’s lifetime)

- Production site cost factors (labor rates, labor burden, electricity costs, etc. are subject to change over the product’s lifetime)

Updated global production site and machine data with the latest actuals

To be able to continuously increase the value of your purchased and inhouse-manufactured products, a reliable database is indispensable as a basis for decision-making.

We continuously extend the machine database, add new machine classifications, and replace outdated machines to be economically and ecologically up to date. With version 9.2, we provide 220 new machines in a variety of classifications. We are continuously improving this list and updating and enhancing the reference data content frequently and adjusting values where needed within the database maintenance. This enables you to calculate and simulate costs that support important company decisions and help you stay away from those expensive mistakes.

Updated reference data for Tool Costing

As we continue to update reference data, we continue to support more accurate tool quotes and should cost calculations by providing updated steel prices, spring prices, and reference tool shop work centers as also introducing new substances. As a result, the information in the quotation calculation is up to date.

Reusable shift models supporting faster cost calculations

The shift model plays an important role in the calculation of hourly rates for a machine and labor burden in a manufacturing step and can be for example different for regions, plants, and suppliers. You can enforce the reuse of a standard shift model by introducing it to our master data service, e.g. associated standard shift models to your own production sites to be used by everyone. This enables you to store different shift models with different validity parameters in the master data and reuse them in the calculation. It improves the usability, and calculation speed, and reduce the failure rate of manual inputs.

Increased calculation speed due to the enhanced full-text search

With version 9.2 we have focused on improving the experience of the full-text search. One of the top priorities was to achieve re-use within the search and we have fulfilled this by introducing the new capability “saved search”. This allows you to create personal search queries which can be saved and re-used. Additionally, you can shared search queries among your team by making them public. On the topic of the filters, we increased the performance and provide additional user settings for your convenience.

Further improved and new capabilities in Teamcenter Product Cost Management

Teamcenter Product Cost Management 9.2 includes further enhancements and new capabilities to support improved usability and increased performance.

With the new updates, you can move forward, from a best-guess cost calculation to a methodical and sound assessment that is built on transparency and flexibility.

Learn more about Teamcenter Product Cost Management version 9.2 and check out the other product cost management blogs.