Usage BOM | Streamline downstream collaboration

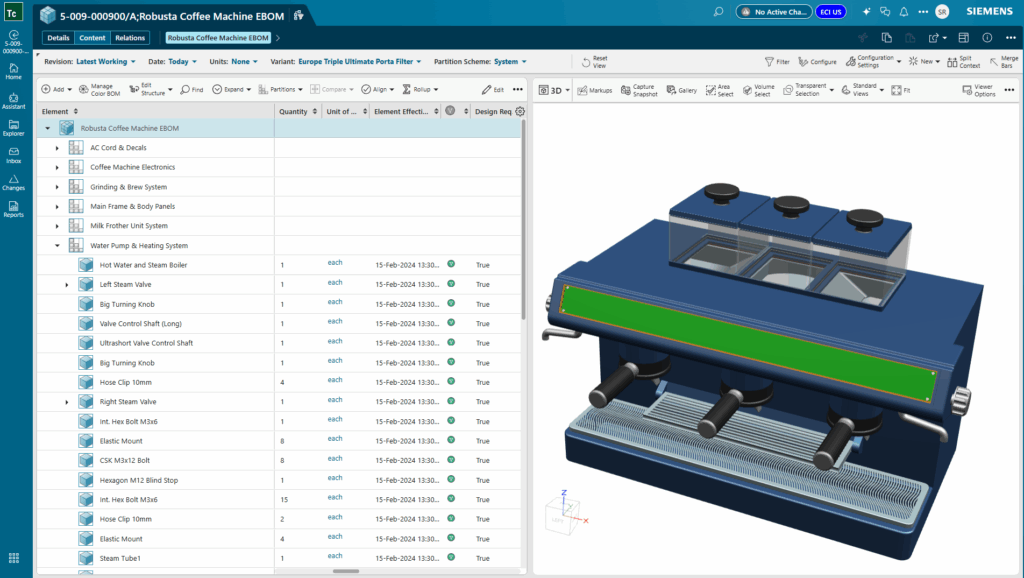

In today’s product development landscape, collaboration between engineering, manufacturing, and service teams is more critical than ever. As products grow in complexity and variability, traditional BOM management approaches can create bottlenecks and slow down innovation. With the Teamcenter 2512 release, Siemens introduces usage BOM, a game-changing capability that transforms how organizations manage their engineering BOMs (EBOMs), enabling true cross-functional collaboration, streamlined change management, and scalable performance for even the most complex products.

🤔 What is usage BOM?

Usage BOM is a new paradigm for managing product structures in Teamcenter. Unlike the traditional assembly BOM, which is revision-centric and often managed by a single author, usage BOM is occurrence-centric. This means each part usage in the BOM can be managed independently, supporting fine-grained change control and concurrent editing by multiple engineers. The result is a more flexible, collaborative, and scalable approach to BOM management.

🤝 Collaboration across disciplines

One of the standout benefits of usage BOM is its support for true cross-functional collaboration. Multiple engineers across engineering, manufacturing, and service can edit the BOM concurrently. This parallelism is especially valuable for organizations with high product variability, frequent changes, or global operations. Instead of waiting for sequential updates or dealing with locked structures, teams can work together in real time, accelerating development and reducing errors.

Key collaboration features:

- Multi-author, concurrent editing of BOM structures

- Independent management of BOM lines, eliminating bottlenecks

- Real-time visibility into all in-process changes

🔁 Occurrence-level change tracking

Traditional assembly BOMs require a new assembly revision for every change, which can be cumbersome and slow. Usage BOM introduces occurrence-level change tracking, allowing each BOM line to be managed independently. This means changes can be made out-of-sequence, tracked per occurrence, and released without revising the entire assembly. The result is faster, more flexible change management and improved traceability.

Benefits:

- Fine-grained control over individual part usages

- Simplified handling of out-of-sequence revisions

- Enhanced auditability and compliance

🖇️ Automated alignment and effectivity

The Teamcenter Engineering BOM automates the alignment between design and part structures, ensuring real-time synchronization and reducing manual effort. With usage BOM, it supports full effectivity by date, unit, or milestone, making it easy to manage regional customization, modular kits, and service-specific parts. This automation not only improves accuracy but also streamlines downstream processes.

Highlights:

- Automated design-to-part alignment

- Effectivity-driven management for regional and modular variations

- Native support for service-only parts and concurrent planning

📈 Scalability and performance

For organizations managing high-volume, high-variability products, scalability is essential. Usage BOM’s flat structure improves performance, making it ideal for complex programs such as automotive, aerospace, and industrial machinery. By eliminating unnecessary duplication and supporting concurrent engineering, usage BOM ensures that BOM management scales with your business needs.

👨🔧 Downstream benefits: MBOM and SBOM

The impact of usage BOM extends beyond engineering. In manufacturing, usage BOM enables concurrent collaboration, fine-grained change control, and improved plant BOM management. Changes can span across revisions without duplication, supporting global manufacturing and complex effectivity needs.

In service, usage BOM allows for occurrence-level control, regional effectivity, and the addition of service-only parts—visible only in the service view. Multiple service teams can plan concurrently, improving service accuracy, accelerating response to field changes, and enhancing compliance.

Downstream advantages:

- Streamlined manufacturing BOM and service BOM creation

- Support for service-specific and region-specific structures

- Improved change propagation and lifecycle traceability

💡 Learn more about BOM management

Usage BOM in Teamcenter 2512 is more than just a new feature. It’s a strategic shift in how organizations manage product structures. By enabling true collaboration, flexible change management, and scalable performance, usage BOM empowers teams to innovate faster, reduce errors, and deliver better products to market. If your organization is ready to break down silos and streamline downstream collaboration, usage BOM is the future. Learn more about BOM management in Teamcenter here.

📖 Complete guide to PLM

Simplify product lifecycle management – innovate faster, collaborate better and cut costs

No matter how you choose to deploy Teamcenter,

you get the same proven solutions designed to help you innovate faster.

Table of Contents