Interoperable digital twins for supplier collaboration

🌍 Driving interoperability with Asset Administration Shell

In today’s manufacturing and engineering landscape, companies rely on a vast network of suppliers to deliver innovative products. Yet, collaboration across company boundaries is often hampered by fragmented data formats, manual processes, and a lack of interoperability. Most organizations still depend on manual data searches, file conversions, and repeated communication loops to exchange product information, technical documentation, and change notifications. Engineering teams spend significant time identifying, completing, and converting data from suppliers—often across incompatible systems and formats.

🌉 Bridging the supplier collaboration gap

Issues with interoperability

- Data silos: Supplier and OEM systems rarely “speak the same language,” resulting in isolated data that’s difficult to aggregate or update.

- Manual effort: Engineers must manually search for information, verify its accuracy, and fill in missing details. This slows down innovation and increases the risk of errors.

- Quality and traceability: Without standardized digital twins, it’s challenging to ensure data quality, track changes, or comply with regulatory requirements.

- Limited automation: The lack of interoperability prevents automated workflows, making collaboration slow and resource-intensive.

To bridge this gap, companies have relied on custom integrations, proprietary data formats, and ad-hoc solutions to exchange information. These approaches are costly to maintain, difficult to scale, and often fail to deliver the seamless collaboration needed for modern engineering.

🤖 Digital twins for supplier collaboration

Digital twins are virtual representations of physical assets, capturing their structure, behavior, and lifecycle data. They are essential for driving innovation, efficiency, and traceability in today’s engineering and manufacturing environments. However, true value is unlocked when digital twins are interoperable—able to be exchanged, updated, and understood across company boundaries and systems.

📤 What is the Asset Administration Shell?

The Asset Administration Shell (AAS) is the standardized format for digital twins in Industry 4.0. It provides a universal “container” for all asset-related data—technical documentation, 3D models, sustainability metrics, product change notifications, and more—making digital twins interoperable and actionable across the supply chain.

AAS is formalized in IEC 63278 and designed to be technology-agnostic, supporting XML, JSON, RDF, and integration with standards like OPC UA and AutomationML. This ensures digital twins created in one system can be seamlessly exchanged and utilized in another.

The Industrial Digital Twin Association (IDTA) defines and maintains the AAS standard, building a global community of over 110 members from 17 countries. IDTA’s work ensures that digital twins are not just company-specific models, but industry-wide assets that drive collaboration and innovation.

🪙 Why is Siemens investing in AAS?

Siemens is committed to making digital twins truly interoperable. By investing in AAS, Siemens enables:

- Supplier collaboration: Suppliers and OEMs can exchange digital twin data effortlessly, reducing manual effort and accelerating engineering cycles.

- Regulatory compliance: Digital twins in AAS format fulfill new EU Digital Product Passport (DPP) requirements for traceability and sustainability.

- Efficiency and innovation: Interoperable digital twins eliminate data silos, enabling faster decision-making and new digital services.

- Customer demand: Leading suppliers and OEMs across industries such as electronics, automotive, aerospace, and industrial machinery are requesting AAS support for streamlined data exchange.

👍 What are the benefits of AAS?

- Interoperable digital twins: AAS enables digital twins to be exchanged and updated across data spaces, simplifying supplier collaboration and product change management.

- Time and effort reduction: Evaluations show up to 79% reduction in data completion time, 67% in structuring, and 37% in identification tasks.

- Regulatory fulfillment: Supports compliance with EU DPP and other international standards.

- Customer value: Immediate access to complete, standardized data accelerates value creation and innovation.

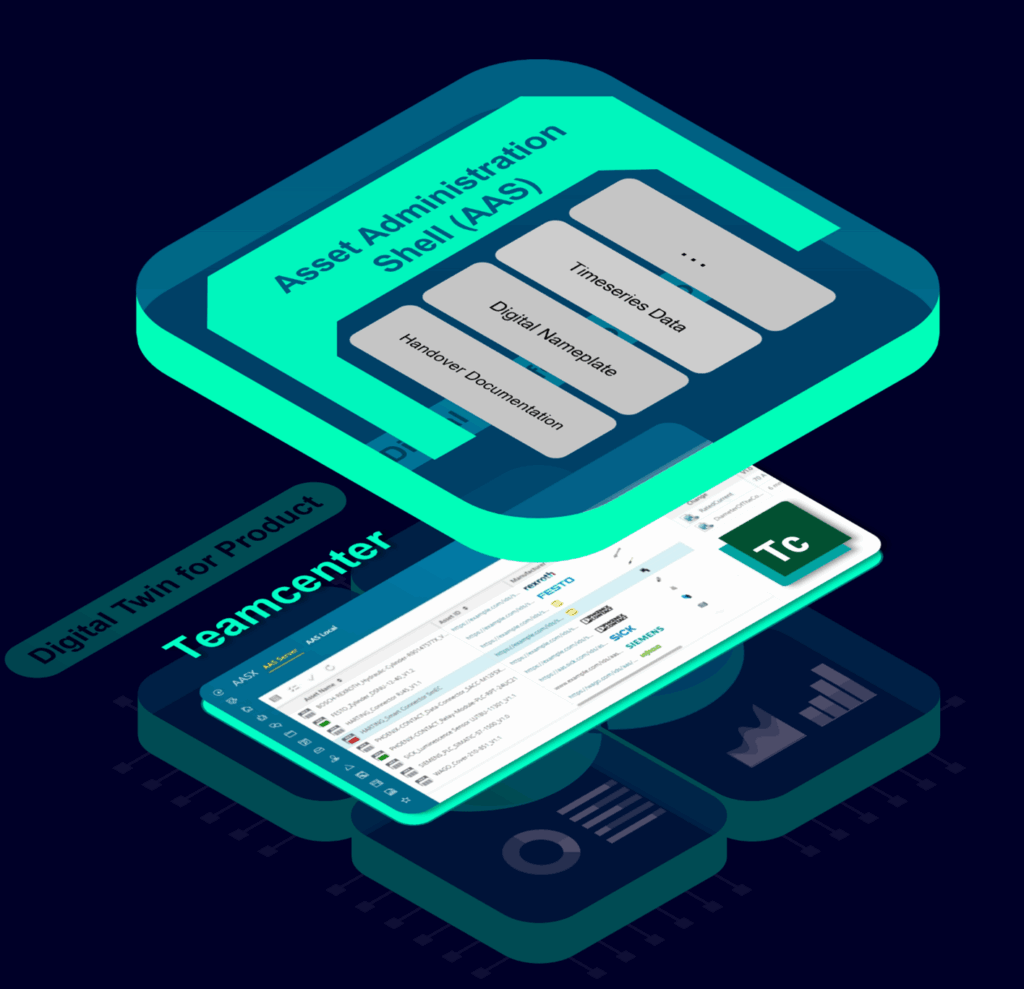

📬 AAS now available in Teamcenter

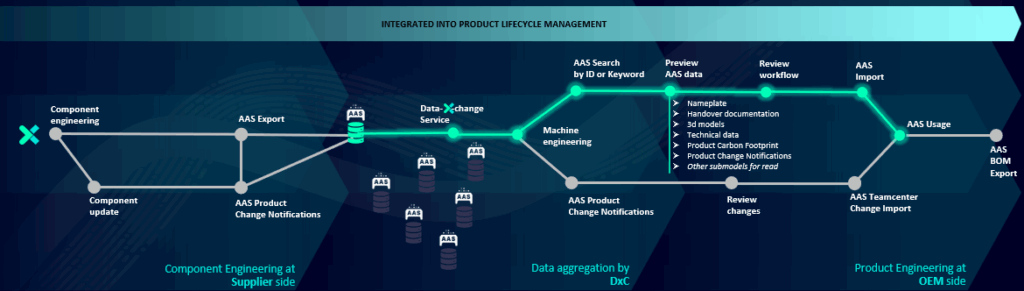

With Teamcenter 2512, Supplier Connect introduces full support for the AAS format, making digital twin data exchange between suppliers and OEMs seamless and standardized:

- Import/export AAS data: Exchange digital twins for machine engineering and component updates.

- Aggregate supplier and OEM data: Manage all digital twin aspects—nameplate, documentation, 3D models, technical data, carbon footprint, and change notifications—in one place.

- Search and review: Find and review digital twin data by ID or keyword, ensuring quality and traceability.

- Quality and efficiency: Integrated workflows guarantee data quality and efficient exchange, supporting both cloud and on-prem PLM deployments.

👷♂️ AAS use cases

- Efficient engineering: Digital twins in AAS format streamline supplier collaboration, reducing manual effort and accelerating innovation. For example, Bausch+Ströbel achieved significant time savings in component selection and technical information exchange.

- Digital product passport: Teamcenter’s AAS capabilities help customers meet regulatory requirements for digital product passports, providing unique asset identification, sustainability data, and compliance documentation as part of the digital twin.

- Industry adoption: Early adopters in batteries, electronics, automotive, and aerospace are leveraging interoperable digital twins for standardized data exchange, driving value across the supply chain.

There is no longer any need to modify, search for, and complete the data, so we can directly begin our value-creating activities…

Erich Bauer, Vice President of Research & Development at Bausch+Ströbel

⏩ What’s next?

Now is the time to assess your digital twin strategy, explore AAS benefits, and prepare for the future of interoperable supplier collaboration. Learn more at: https://plm.sw.siemens.com/en-US/teamcenter/solutions/supplier-management-software/

📖 Complete guide to PLM

Simplify product lifecycle management – innovate faster, collaborate better and cut costs

No matter how you choose to deploy Teamcenter,

you get the same proven solutions designed to help you innovate faster.