Launch Forth & Digital Manufacturing Deliver USMC Module Vehicles

Direct digital manufacturing is fast, precise, and repeatable. It encourages innovation by shrinking the gap between design and fabrication and easily accommodates complex geometries that can’t be made by traditional methods. It also allows for easy collaboration with people around the world.

The digital thread is a communication framework that connects materials, design, processing, and manufacturing.The digital thread ensures that the right information is delivered at the right time in the manufacturing process. It connects the as-planned design with the as-built reality, generating actionable feedback along the production line. This brings us to the Modular Logistics Vehicle Challenge hosted by Launch Forth.

THE CHALLENGE:

Using Direct Digital Manufacturing, Modular Logistics Vehicle (MLV) will exemplify the innovative-hacker spirit of the Marines, turning it into something available to the entire Marine Corps.

Using Direct Digital Manufacturing, Modular Logistics Vehicle (MLV) will exemplify the innovative-hacker spirit of the Marines, turning it into something available to the entire Marine Corps.

At the Marine Corps Twentynine Palms base in California, a team of Marines has turned a fleet of standard off-the-shelf utility vehicles into highly customized vehicles that can now serve a wide range of diverse tasks. They employed ingenuity to transform stock vehicles into a multitude of use cases, embodying the grit, creativity, and technical proficiency that define the Marines. Inspired by these Marines, Launch Forth is designing a new modular vehicle system that meets a range of logistical missions. This Modular Logistics Vehicle (MLV) will exemplify the innovative-hacker spirit of the Marines, turning it into something available to the entire Marine Corps.

In this Challenge, Launch Forth asked those interested to design a new type of light vehicle with modular elements that will allow for the vehicle to meet at least the four use-cases listed below.

The design should meet these 5 design principles.

Modular – Interoperability is all that matters .

Breakable / Hackable – Design for the need, but anticipate the unexpected.

Understandable – Intuitive for users of all types to use, modify and share functional builds

Function over Form – Fewer format features maximizing usability over aesthetics

High Capacity – Room to hold more. More people, more equipment, more functions.

Now, you may be saying to yourself…HOW COOL! But, what does Teamcenter have to do it with the challenge?

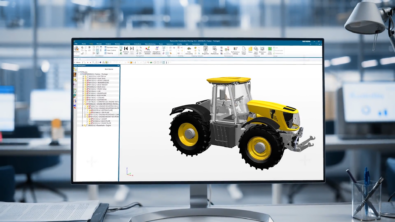

The entries to the USMC Modular Logistics Vehicle challenge are currently being reviewed, revised, and judged. These steps are the beginning strands of what will become a digital thread for the Marines. Launch Forth will upload the winning entries and their revision history into Teamcenter. This digital thread will continue as they bring the winning concepts to life through direct digital manufacturing and deliver the vehicle and its technical data package to the Marines– all of which will be captured by and orchestrated within Teamcenter.

The hackable designs enable the Marines to hone the vehicle’s form for their ever-evolving needs. As the Marines create these future versions, Teamcenter will provide the Marines with the revision history, fabrication instructions, and workflow management needed to micro-manufacture quickly.

A robust digital thread– embodied through direct digital manufacturing and managed by Teamcenter– provides all the information that the Marines need for rapid prototyping and manufacturing in a tidy digital package.

Check out Launch Forth’s blog post covering the topic!

Read more about Launch Forth’s Modular Vehicle Challenge on their website.