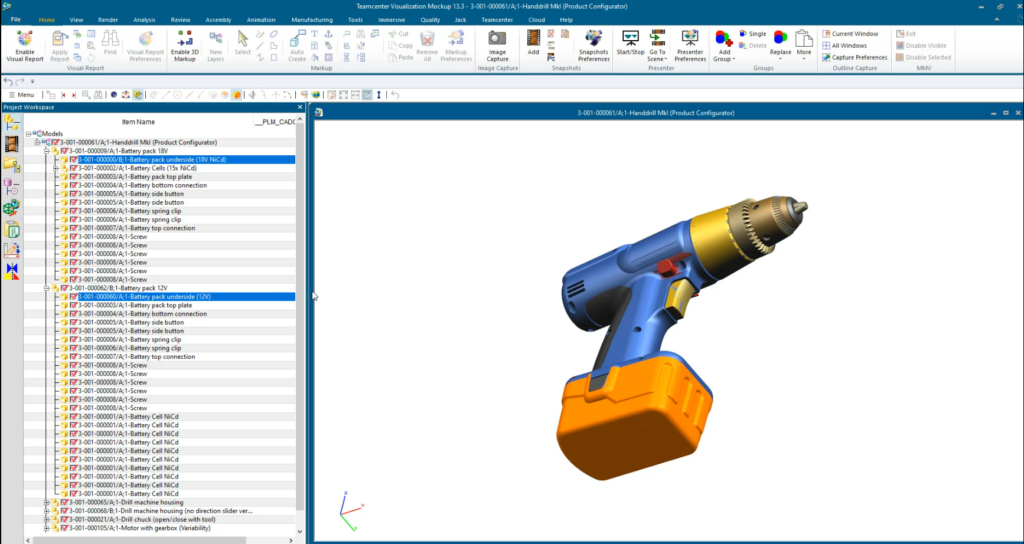

Teamcenter Product Configurator

A better approach to CAD clearance analysis

A component that is only a few centimeters out of place could create a collision with a neighboring component. It would make the assembly impossible. As a result, the CAD team will have to keep working on the design to find and resolve the issue.

Manufacturing relies on proper clearance between parts.

Modern CAD design tools have replaced hand measurements on drawings and physical mockups. Now, designers are able to digitally identify collision issues more quickly with clearance analysis. This greatly improves their productivity as a result.

These CAD tools are adept at collision testing on individual assemblies, but…

What if you work with configurable products?

Design Collision Issues

Customizable and engineer-to-order products can have tens or hundreds of configuration combinations. For this reason, testing each one individually can prove to be an arduous process. Could you simply test a few reference variations for collisions? It’s a shortcut, but it also introduces risk into your development process.

Discovering a collision error in even one variant during the prototyping phase requires costly redesign cycles. Consequently, you would also need to investigate whether any other configurations are affected. One small issue within a configurable product can have a ripple effect, thus creating major headaches for the entire development team.

Solution: Teamcenter Product Configurator

Teamcenter Product Configurator is a powerful tool for managing variability from product planning to manufacturing and service. Leading companies like CEVT use Teamcenter Product Configurator to manage product line complexity by capitalizing on the commonality across their product variants.

With this technology, you can leverage a common definition of variability. Product Configurator closes the loop on requirements and checks validation rules against all product variants before production.

Validate your product configurations in the digital phase!

Now, Siemens has added a powerful new integration between Product Configurator and Clearance Analysis, a tool within the Teamcenter Visualization framework.

Leverage this new capability! You can perform virtual collision testing across all buildable product configurations. With this, you can validate faster and streamline the product’s release to manufacturing.

Let’s look at this use case

An engineer looking to validate their 150% BOM must answer the question:

Are there any possible geometric collisions between parts in any configuration of my product?

You can detect collisions across those variants with CAD clearance analysis. Then, simply correct the geometry or create exclusion constraints to ensure that combination never gets sold.

Finding potential collisions would typically take a user days, if not weeks. But with an intelligent connection between configuration and clearance knowledge, Product Configurator with Teamcenter Visualization can to this in minutes.

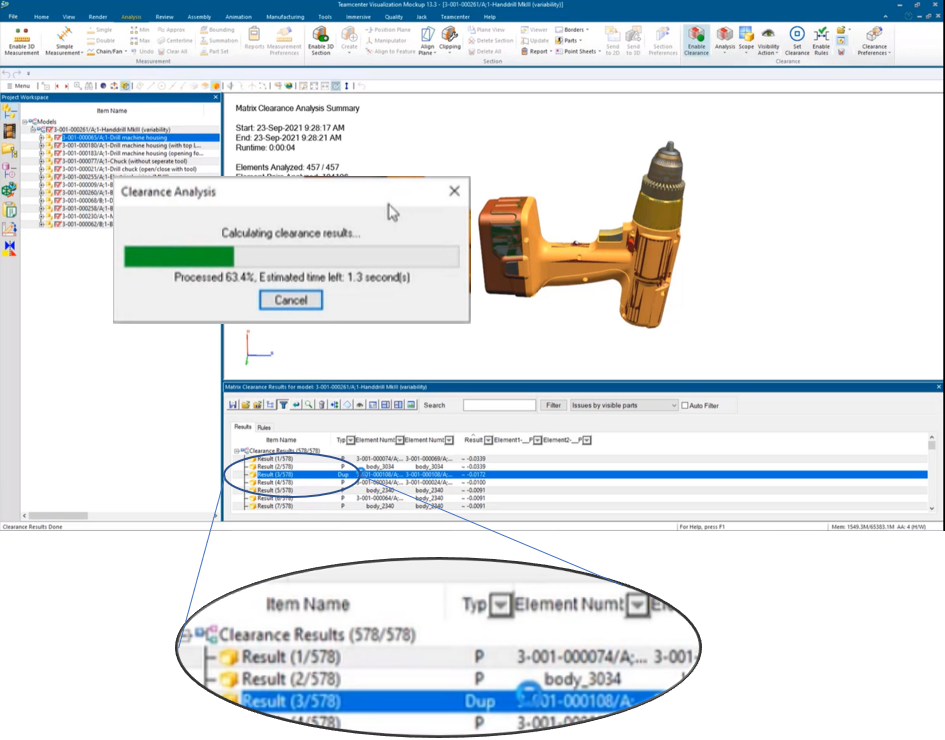

Clearance analysis

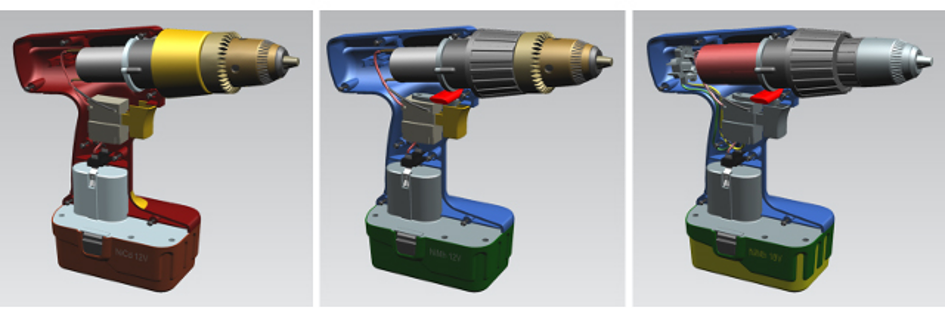

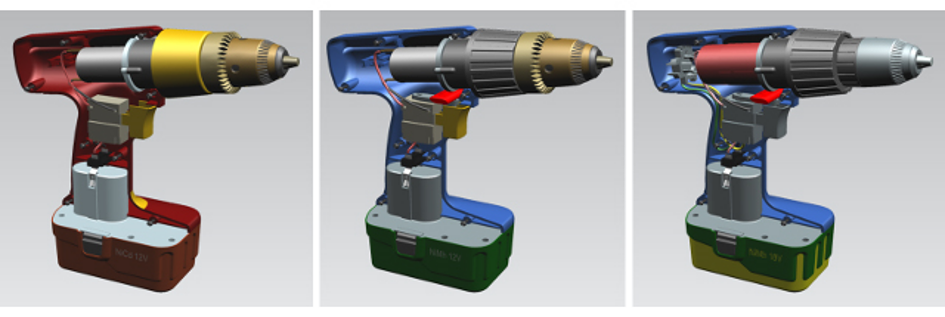

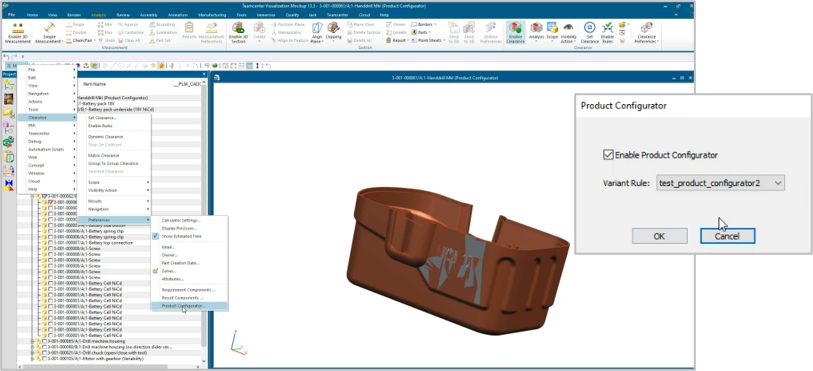

The following example shows the result of clearance analysis within a hand drill assembly.

First, the tool finds multiple overlapping alternative parts, indicating where clashes between parts have not been resolved.

The analysis shows a potential collision issue on the underside of the hand drill’s battery pack. Two parts lay on top of each other, but the user must check if these parts could actually coexist in a configured finished product.

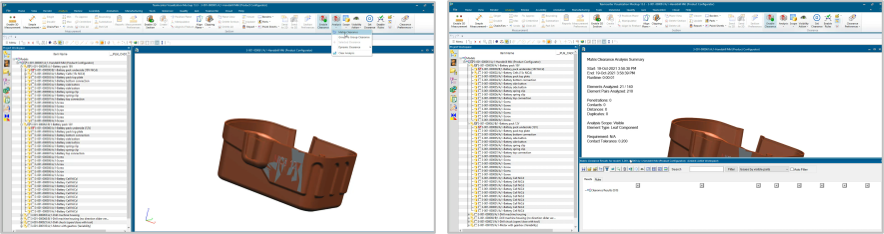

In this step, we simplify the scenario to the absolute minimum. There are just two components remaining for the clearance calculation process. Now using Teamcenter Visualization, you can activate variant recognition for clearance analysis.

Finally, you perform the clearance calculation to evaluate the variant conditions (matrix clearance shown here). Since those to components exist within separate product variants and would never be manufactured together, no result is produced.

3D visualization supports the entire process. In just a few simple steps, the user identifies and resolves critical clearance issues across multiple product variants.

Teamcenter Product Configuration, with its clearance analysis integration, provides a solution for coordinating the complex lifecycle of configurable products and streamlining their development.

How can you meet the rising demand for product personalization without driving up costs?