An Integrated Product Definition for a Consistent Bill of Materials

Innovation comes in many forms. It’s the discovery of a new ski jumping technique that forever changes the sport. It’s companies trying to meet their own challenges and their customers’ challenges.

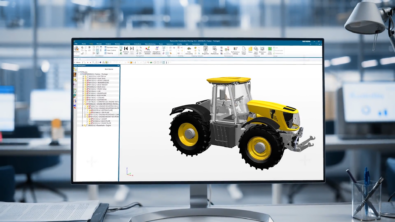

But product complexity can stifle innovation. Siemens PLM customers manufacture some of the most unforgiving, complex products on the planet, but their customer bases demand flexibility and choice. What can we do to help our customers meet their own customers’ demands and still be innovative?

In this series, we’re exploring how an Integrated Product Definition, or IPD, addresses increasing complexity to help drive innovation.

An Integrated Product Definition Addresses Fragmentation

Today’s product definition landscape is fragmented. This is a major customer challenge that gets in the way of gaining product clarity. Virtually all companies I meet and talk with struggle with this. Multiple departments often have their own version of the product definition, and they need to reconcile changes through time-consuming processes across disconnected systems.

A colleague of mine, Ashok Krishnamurthy, has talked about how product definitions nearest to manufacturing have typically been the de-facto product masters. This happens, he says, because “not disrupting production has traditionally been considered more critical than the speed of consuming product innovation.”

But the inability to seamlessly or efficiently reflect upstream changes to the production master slows innovation during planning and engineering. This must change: failing to innovate fast enough could lead to a company’s decline or downfall. A big part of supporting customer needs to increase the speed and accuracy of product definitions and innovation involves enabling connectivity and collaboration across different communities. The product is at the core of this collaboration: its features, which subsystems need improvements, how much it costs and weighs, where it will be produced and which supplier to source from. This needs to quickly, efficiently and concurrently happen. A process with many opportunities for mistakes no longer cuts it.

We need to integrate fragmented pieces for a consistent, visual view of the bill of materials for each stakeholder without duplication. An Integrated Product Definition promotes a high-definition approach to this. It supports product-level impact analysis, reuse, coordinated product change management, BOM consistency and complexity management. The engineering definition is enhanced with rich information that supports multiple consumption and planning purposes. Each stakeholder can directly derive the right view of the engineering product definition without duplication or complex reconciliation.

We’ve been discussing many aspects of an Integrated Product Definition over the last several months. From configuration management, product variant management, and guided product configuration, to a closer look at master data management and product architecture breakdowns. We recently concluded a series of topics around configurator for total variability management. In this series, we are exploring IPD from the perspective of real world examples. Next time, we’ll take a closer look at how a powertrain engineer, a freshwater system designer and heavy equipment sales engineer can each leverage IPD.

Other discussions in this series include:

An Integrated Product Definition: Driving Innovation

An Integrated Product Definition: Solving Real World Problems