Collaborative Manufacturing is Critical for Success in Today’s Heavy Equipment Industry

Heavy Equipment is getting smarter with collaborative manufacturing

When you think about manufacturing trends, such as Electrification and Autonomous, your first instinct may be to think about the Automotive industry. But these trends are as relevant in the Heavy Equipment industry as they are anywhere else.

Take Autonomous, for example: In the Automotive industry, there are numerous factors that make it very difficult to realize fully autonomous driving. Multiple lane roads, crowded traffic, stop lights and road signs all contribute to this challenge.

Now think about the Heavy Equipment industry: An autonomous application may be a single tractor in a large open field with no traffic signals to obey. This makes it a much better candidate for autonomous technology and this is being recognized more and more throughout the industry.

In order to meet the challenges brought on by these trends, Heavy Equipment OEMs are forced to deal with more stringent requirements, increasing product complexity, ongoing improvement initiatives, and globally distributed operations, among other things.

Heavy Equipment OEMs know that a business-as-usual approach will not suffice if they are to be successful in this increasingly complex environment. As a result, a need for digitalization is apparent. As a first step on the road to digitalization, Heavy Equipment OEMs are starting to digitize legacy processes.

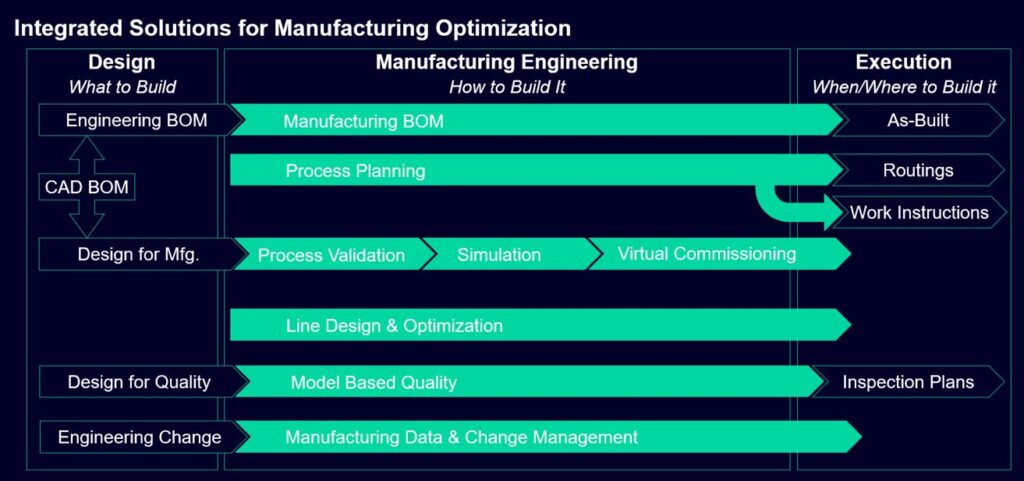

Progressing past simple digitization and realizing full digitalization in Heavy Equipment Manufacturing is a huge undertaking. To optimize manufacturing productivity and win in the global marketplace, Heavy Equipment manufacturers must collaborate efficiently throughout their entire organization by establishing and leveraging a common digital thread from design to execution and beyond. And Siemens Digital Industries Software provides the solutions required to achieve this vision.

Siemens makes it possible to realize a true production digital twin by leveraging solutions that enable the digital thread. These solutions support true collaboration at all stages of the product lifecycle. Manufacturing Planning can collaborate with Design Engineering during early stages of the product design while they still have the ability to influence the design, and the cost of doing so is low as compared to making a design change much later in the lifecycle.

The high-level digital thread solutions that enable the collaboration required to be successful in the Heavy Equipment industry are as follows:

- Product Configuration – essential for a Configure-To-Order industry, the ability to configure a Manufacturing Bill Of Materials (MBOM) into a specific customer order

- Manufacturing Planning – development of the Manufacturing Bill Of Process (BOP)

- Design & Validation – the ability to virtually validate the process plan to eliminate potential shop floor issues

- Production Support – enabling efficient production with tools to support layout development and Electronic Work Instructions

- Optimization & Execution – interfacing with manufacturing execution systems and leveraging a digital twin to continuously optimize production

- Data & Change Management – the ability to handle the large amounts of data and changes that occur throughout the product lifecycle

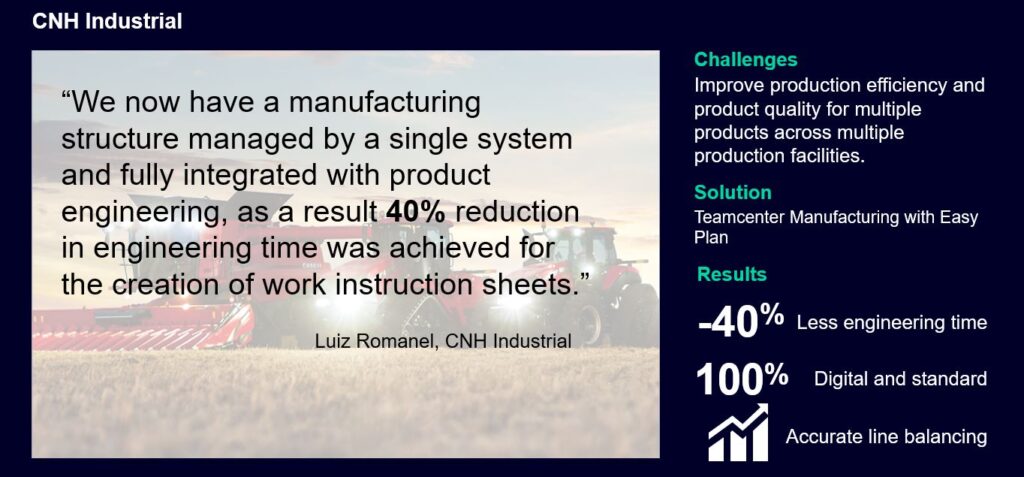

These solutions close the digital gap from product design to production execution and make digitalization a reality in the Heavy Equipment industry. For example, take Siemens Digital Industries Software customer CNH Industrial, a global agricultural and construction equipment and powertrain provider with 67 production sites worldwide. CNHi Brazil has implemented Teamcenter Easy Plan and achieved a 40% reduction in engineering time. With this manufacturing process management and planning solution, they’ve implemented electronic work instruction digitalization and standardization across all plants in Brazil, and improved their ability to conduct accurate time analysis with line balancing for their products. This has helped them to eliminate the use of multiple software solutions, improve the overall process efficiency across plants, and increase process quality by reducing errors.

For more information on Siemens Collaborative Manufacturing solutions for the Heavy Equipment industry, please visit us at: https://www.plm.automation.siemens.com/global/en/industries/industrial-machinery-heavy-equipment/heavy-equipment/collaborative-manufacturing.html

Learn More About Manufacturing Process Management with Teamcenter Easy Plan

Visit siemens.com/easyplan to learn more about task-based solutions for Manufacturing Process Planning

Try Teamcenter Easy Plan today, with a free-30 day software trial

See a demonstration of Manufacturing Process Planning with Teamcenter Easy Plan 6.0