Startup Spotlight: The Fuel

Founded by Matt Plested and Jim Blyth, The Fuel is an industrial design consultancy based in the United Kingdom that specializes in the definition and creation of mass-produced consumer and professional products for manufacturers and brands alike.

The Fuel, a dedicated member of the Solid Edge for Startups program, relies on Solid Edge to design the visual appearance, physical interactions, and all other aspects of the product experience to create devices that are easy to use and easy to sell, balancing the needs of human behavior, technology, and marketing. The Fuel has worked with a broad range of clients for over two decades, ranging from established global brands to newly funded startups, many of which have become repeat long-term relationships.

“The key areas that we operate in are consumer electronics, telecoms, smart home IOT, domestic appliances, marine electronics (technology products for boats and ships), as well as gaming accessories for consoles such as PlayStation and Xbox,” explains Plested.

Why Solid Edge?

The Fuel started using Solid Edge nearly a year ago and hasn’t looked back. To date, the company has been a Solid Edge user for just over 11 months. “We’re running three Solid Edge licenses at present , but we have plans to expand in the future,” says Plested.

“As we started working with Solid Edge, we decided that we wouldn’t need any training on the software”, Plested reflects. “On the one hand, we weren’t new to the topic and already had extensive experience in other CAD systems, but on the other hand, we knew that we needed to be productive in the short term to produce designs quickly and efficiently.”

Plested and Blythe were pleased when they discovered that Solid Edge was as intuitive as it was easy-to-learn. At the same time, Solid Edge provided them with a wide range of state-of-the-art product development functionalities that they could onboard to the system and start productively working within literally no more than two days. Solid Edge provides them with a portfolio of software tools for all aspects of product development – from CAD design and rendering, to simulation, manufacturing, data management, and more.

“There were one or two things that we struggled with at the outset, which we simply contacted our Solid Edge partner reseller OnePLM about,” says Plested. “We explained to them exactly what it was we wanted to know, and they told us straight away what to do. With this additional back-up support, it was really easy to pick up.”

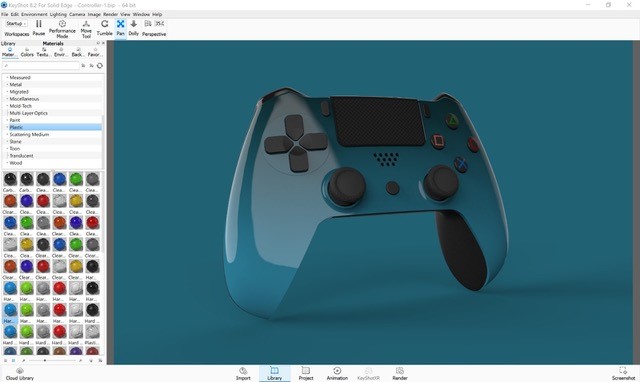

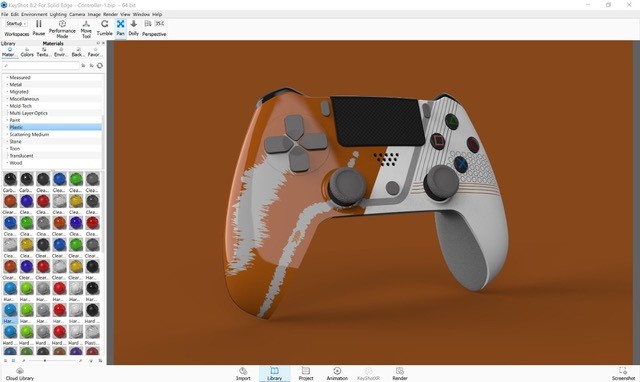

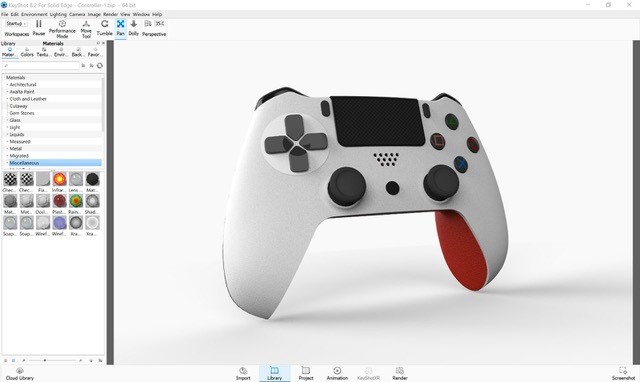

Using Solid Edge for Rapid Photo-Realistic 3D Rendering

The Fuel relies heavily on the built-in 3D rendering capabilities in Solid Edge to create photo-realistic images and animations directly from within a modeling environment. This helps them to rapidly visualize new product designs to both internal teams and customers.

“Solid Edge is a great product for us to use for both rapid design concept form exploration, as well as detailed design for manufacturing,” explains Plested. “The 3D rendering capabilities are a particularly good feature for industrial designers, allowing us to instantly review designs with highly realistic materials and lighting with the click of a button.”

“The integrated 3D rendering capability is a feature we’ve wanted for years,” says Plested. “Previously, it was very time consuming to go between 3D solid modelling and a good photo-realistic rendering software, meaning design reviews tended to be carried out on-screen in the solid modelling package in the interest of saving time. When reviewing concepts in this way, everyone has to imagine how the design would look in the correct color and materials, with realistic lighting, which actually makes the review very inaccurate because not everyone can imagine it in the same way. […] That’s why Solid Edge is so valuable to us. We realized when we started working with Solid Edge that its integrated 3D rendering capabilities are absolutely brilliant. You simply hit the button to get an instant rendering. From a industrial design point of view, that’s an amazing productivity feature.”

Easy 3D Printing & Additive Manufacturing in Solid Edge

The first time Matt and Jim started to experiment with the additive manufacturing and 3D printing functionalities in Solid Edge was when they started developing initial designs beyond first concepts and into detailed designs for manufacturing. “As part of our design process, we do a lot of data sharing,” explains Blythe. “Initially, we use our data to create outsourced 3D printed prototypes that validate the visual appearance, proportions, and user experience of the design. We then work very closely with the clients engineering teams to optimize the product size and build, which requires lots of seamless data exchange for clear communication. The beauty is that data exchange in Solid Edge is really good.”

Solid Edge 3D Printing supports end-to-end workflow, from design-for-manufacture using additive techniques, to preparing and outputting designs to 3D printing hardware and services. “Solid Edge allows us to load design information and feedback into our engineering teams’ system while still being able to go back and forth so that they can recreate our design intent right the first time, with less rework,” says Plested. “We’re able to go back and forth on product development issues, such as the placement of specific buttons and LEDs, as we simultaneously design and co-engineer both the product exterior and internal electronics.”

Looking Ahead: What’s Next for The Fuel?

At the moment, The Fuel team is working on products for organizations like Hive Connected Homes and Raymarine. “As an industrial design consultancy, most of our work involves designing products for the business to consumer (B2C) market,” says Plested. “However, sometimes the distinction between business-to-business (B2B) and B2C can be a bit gray because everything we design ends up being used by a consumer at some point. The only difference is who buys the product in the first instance.”

The Fuel relies on its stellar reputation in consumer electronics, especially within the telecom and smart home IoT sector. “Our reputation allows us to rely on mostly word-of-mouth marketing networking,” explains Plested. “In addition, publicity from design awards and a constant social media presence have really helped us build out our reach. In general, most brands are happy for us to say that we designed their product and often encourage us to be associated with it, while occasionally others prefer our discretion to claim design originality themselves.”

The Solid Edge for Startups Program: Fueling Innovation

The Fuel are entering their second year of the Solid Edge for Startups program. “We’re happy with the software, so we have no reason to switch from the winning team,” says Matt with excitement. “It does everything we want. We employ experienced designers who have already worked with a variety of different CAD systems. Solid Edge is so easy for them to pick up.”

When asked what advice Matt would give to other entrepreneurs who are thinking of starting a design company or bringing a product to market, here’s what he had to say:

“Advances in technology have made it significantly quicker and easier to start a design and development company. 20 years ago, much of what we do today would have been restricted to only established and professionalized companies, due to the complex and hugely expensive software and hardware needed to design new physical products. Now, you can do most of the exterior design work from a tablet at home. This ability to create beautiful products cheaply and easily, combined with the rise of crowdfunding sites such as Kickstarter and Indigogo, provides an avenue for a vast amount of new startups both designing and selling products.

The problem with the vast majority of product designs is they aren’t real – they’re just realistic-looking renders – and there’s still a very long way to go before becoming a tangible object in a consumer’s hands. Although you can shortcut the initial design creation process, you can’t shortcut the experience needed to go from design concept to physical product. Everything beyond concept creation requires serious expertise, otherwise costs skyrocket, timescales go way up, and ultimately the product you end up with is far from what you originally imagined.

We’ve seen many good looking products go-through the crowd funding launch process that either don’t ever launch, or come out sub-standard. So my advice to anyone considering creating a new product via this route is seek out experience in creating and bringing designs to market. While it may be the unglamorous element of the process, it is absolutely essential if you want to actually bring a quality product to market.”

To learn more about the Solid Edge for Startups program, visit our site.

Founded by Matt Plested and Jim Blyth, and a member of the Solid Edge for Startups program, The Fuel is an industrial design consultancy based in Surrey Hills, UK, specialized in the design of physical products for brands and technology companies. They identify as masters of crafting beautiful forms and meaningful interactions that allow their clients to produce highly desirable products, with noticeable customer benefits.

Comments