New in Solid Edge 2025: Simcenter FLOEFD

Take a deep dive into everything new in Solid Edge 2025 with a series of blog posts focused on the exciting new features and enhancements in this year’s release. In this blog, learn more about the exciting Simcenter FLOEFD enhancements in Solid Edge 2025.

Faster mesh generation, advanced flow and heat simulation

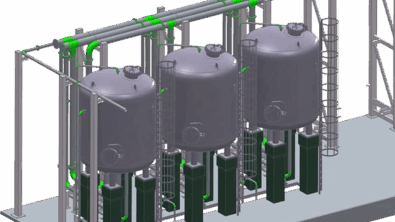

Improved integration with Simcenter FLOEFD for Solid Edge allows you to directly import complex CAD models for analysis, saving time in the simulation setup process. Simplified fluid flow and heat transfer analysis make it easy to evaluate product performance under various conditions. Mesh generation for convergent, faceted and STL geometries is now even faster. With new templates and tools, setting up complex simulations is easier and more streamlined. Additionally, its user-friendly features and robust support resources enable you to design smarter and faster.

Improved Solid Edge integration

Simcenter FLOEFD for Solid Edge enhances integration with Solid Edge’s tools, allowing for smoother data transfer between CAD and simulation environments. This enables you to easily import complex Solid Edge CAD models directly into Simcenter FLOEFD for Solid Edge for analysis, saving time in the simulation setup process and improving overall productivity. In addition to that, Simcenter FLOEFD for Solid Edge supports flow simulation with an embedded computational fluid dynamics (CFD) simulation tool for easy, fast and accurate fluid flow and heat transfer analysis.

Simcenter FLOEFD fields can now be exported in the SCD5 format of Simcenter 3D. This results in a binary file for data transfer from Simcenter FLOEFD to Simcenter 3D. This means that there can be a significant file size advantage using the binary SCD5 format. SCD5 is a specialized binary file format designed for efficient data transfer and storage, particularly in simulation applications. This helps for transferring fields from thermal analysis to a thermo-mechanical stress analysis in Simcenter 3D. You can also export steady state or transient pressure and temperature fields to a CFD General Notation System (CGNS) file using SCD5 mesh file as input data.

Simcenter FLOEFD scene files can now be saved in JT format. The JT file format is an openly published data format, widely used across manufacturing supply chains for sharing and visualizing 3D part and assembly model. This enables viewing of simulation results from Teamcenter using its viewer allowing for more usability.

Flip Chip Ceramic Ball Grid Array (CBGA) and Wirebond CBGA. They are a type of “chip” that you see on a PCB in your electronics devices, they generate heat, and if they get too hot, they will fail. Tools like Simcenter FLOEFD for Solid Edge help simulate virtually a thermal analysis to see how hot they will get. Additionally, it now includes the ability to create detailed models that are Simcenter Flotherm-ready and can be exported for sharing, ensuring consistency and compatibility across different teams and organizations.

Enhanced user experience

The Improved user interface that provides you with a more intuitive and streamlined simulation experience with improved model setup tools, simplified boundary condition definition and enhanced visualization options. These improvements make it easier for you to set up, solve and analyze simulations.

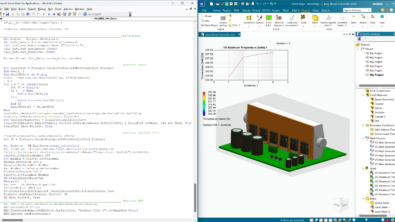

The new EFDAPI covers all existing features and parameters in Simcenter FLOEFD for Solid Edge. The enhanced functionality and improved ease of use enables you to take advantage of automation to shorten simulation workflow.

Additional Improvements

A project template has been added so you can create and modify a PCB reflow oven simulation as a transient study to reflect conditions as a board moves through an oven. The template leverages the project parameters functionality in Simcenter FLOEFD, and the new EFDAPI automation capabilities are used to modify parameters. The approach simulates the reflow process inside a small volume space around the PCB with moving flow boundary conditions instead of simulating the real oven with moving bodies.

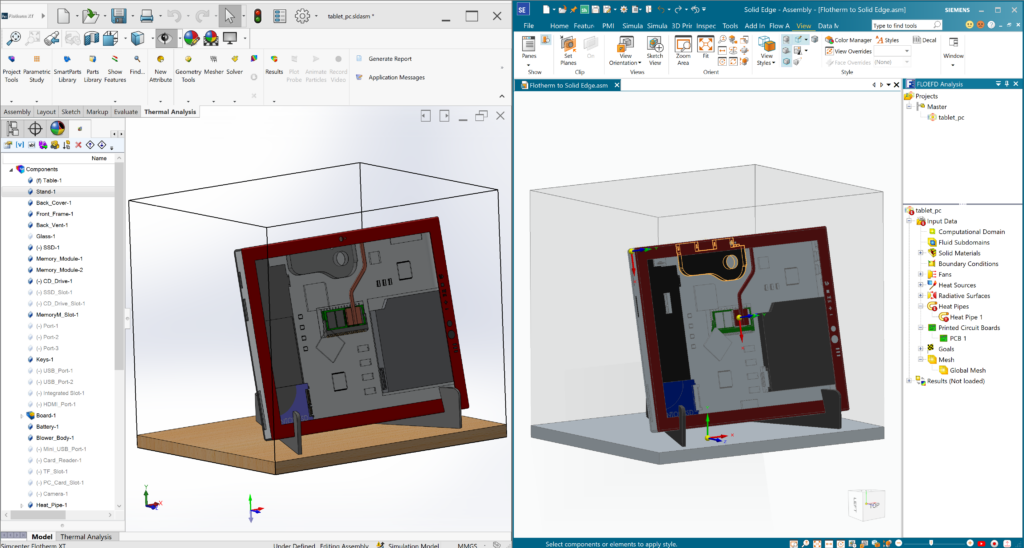

A new ability to transfer models from Simcenter Flotherm XT to Simcenter FLOEFD to utilize Simcenter FLOEFD’s extended capabilities while retaining the original model setup from Simcenter Flotherm XT. Simcenter Flotherm XT is CAD-centric electronics cooling CFD software that enables thermal engineers to shorten development and optimize thermal management of electronics earlier in the process by connecting ECAD and MCAD design flows. Simcenter FLOEFD now supports importing Simcenter Flotherm XT models/projects via the XTXML format, allowing seamless project transfer and enhancing simulation workflows by saving time and reducing errors.

Join the conversation

All of these new features and enhancements in Solid Edge 2025, along with many more, were announced during our live premiere on October 23, 2024.

To learn more about what’s new in the Solid Edge 2025 release, click here.

There are a lot of ways to hear what others are saying about the upcoming release and to connect with other Solid Edge enthusiasts online.

Here are a few ways to join the conversation right now:

- Join our vibrant online Solid Edge Community to connect and interact with other Solid Edge users.