New in Solid Edge 2023: Solid Edge Inspector

We hope you are as excited to dive into everything that’s new in Solid Edge 2023. We will be releasing a series of blog posts about some of the most noteworthy features new in this year’s release of our market-leading product development software portfolio, starting with the all-new Solid Edge Inspector.

Released on October 12, Solid Edge 2023 from Siemens Digital Industries Software gives you the product development tools you need to create, connect, and collaborate. Solid Edge 2023 delivers a new streamlined user experience, greater interoperability with the Siemens Xcelerator portfolio, and improved capabilities and collaboration across common workflows.

Minimize product development time

The manufacturing process is long, laborious, and often riddled with errors due to the reliance on humans to identify, label and extract critical design information. Solid Edge 2023 introduces Solid Edge Inspector, which provides the digital manufacturing capabilities needed to eliminate human error in product inspection with automatic labeling of critical design characteristics, the ability to generate automated reports which include first article inspection reports, and much more.

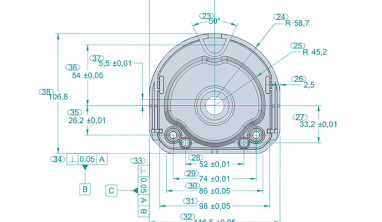

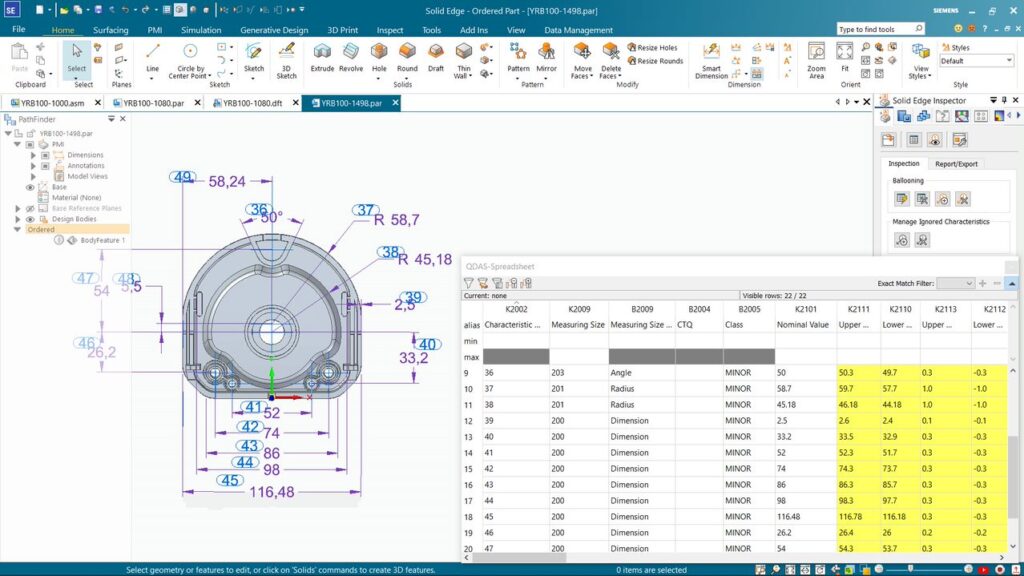

Automatically identify and label critical design characteristics

Solid Edge Inspector enables for a seamless and effortless downstream manufacturing process by automatically identifying design characteristics. Identifying and extracting capabilities range from 3D PMIs to 2D drawings. The effortless and automatic extraction of information provides you with quality data, which will in turn ensure quality management. Inspector allows management to have peace of mind in the manufacturing process because the aspect of human error is eliminated.

Solid Edge Inspector utilizes unique identifiers, better known as balloons, to ensure success in all aspects of the manufacturing process. These balloons house vital information that is in turn provided to the manufacturer. These unique identifiers stay with the product throughout the entirety of its lifecycle regardless of modifications of iterations. The information housed within these balloons is also used in the generation of first article inspection reports (FAI) reports into Microsoft Excel.

Generate first article inspection reports

First article inspection reports are paramount in a successful manufacturing process. These reports are used to verify that a product has met predetermined requirements during the inspection process. Traditionally, these reports were created manually. Therefore, the reports were riddled errors that are time consuming to fix. Solid Edge Inspector can not only generate these reports automatically, but can do so in a fraction of the time it would take a human to do it. The first article inspection reports are automatically generated based on the data provided in the drawing or model.

It’s no secret that time is valuable in all aspects of the manufacturing process. Therefore, efficiency is more important than ever. Solid Edge Inspector includes advanced capabilities that will help the downstream manufacturing process rather than hindering it. Automatic labeling of critical design characteristics using Solid Edge Inspector is 80 percent faster than traditional labeling methods. The introduction of Solid Edge Inspector will significantly improve the manufacturing process by utilizing robust, automatic labeling capabilities and generating automatic reports that will companies time and money.

Learn more about Solid Edge Inspector and other Model Based Definition capabilities →

To learn more about what’s new in this year’s release, visit siemens.com/solid-edge-2023.

Join the conversation

There are a lot of ways to find out what others are saying about the latest release and to connect with industry peers and CAD experts online. Log into the Solid Edge Community to connect and interact with other Solid Edge users around the world and get answers to questions in real-time from Siemens experts. You can also follow the #SolidEdge2023 hashtag on Facebook, YouTube, Twitter, and LinkedIn to see what others are saying on social media.

Comments