Move towards digital manufacturing – use your 3D CAD models to create excellent technical documents

Today, manufacturers are recognizing that their 3D digital models are key for publishing accurate downstream documentation for manufacturing, and for their suppliers, marketers, even consumers.

3D digital data that comes directly from CAD models is increasingly needed in this age of Industry 4.0. Sometimes called the fourth industrial revolution, Industry 4.0 is the current trend in manufacturing towards automation and data exchange throughout the product lifecycle from concept design through to manufacturing and customer service. Industry 4.0 requires that digital models of both the product and manufacturing process are maintained, and also encompasses the Internet of Things for network connectivity for the product itself, and cloud computing to store and provide access to the large volumes of data involved.

As well as being referenced by manufacturing systems, for example for the creation of machining instructions for CNC machine tools, digital models can also be used to create parts catalogs, instruction manuals, installation and service guides, and other technical documents that people access using hardcopy documents, web portals, or electronic PDF files.Industry 4.0 requires that both products and manufacturing systems have associated technical documentation that conveys information in easy-to- use digital formats for everyone involved in product development, manufacturing and service.

Unfortunately converting the original 3D CAD files for technical documentation purposes has typically been a painstaking process that takes time and expertise. These file conversions, and the management of the additional files that are created usually falls upon the busy designer who created the original CAD files. The designers can waste significant time on these non-added value tasks, taking them away from the tasks that are critical to the success of your business such as designing innovative new products and improving existing designs.

Some manufacturers are still taking photographs of a physical prototype to create graphical content, of course this means that the prototype must be manufactured first. Or, downstream users might ask the designer to provide bitmap screen captures of CAD images with a specific orientation. Both these processes are time consuming and a distraction from an innovative and efficient product development process.

According to “The 2014 State of Model Based Enterprise Report,” a study completed by industry analyst Lifecycle Insights, engineers spend more than six hours each week answering questions from consumers about their designs, and an additional 5 hours creating “other documentation”.Clearly engineers are spending too much time on these tedious non-value added tasks! This report contains another revelation from the manufacturing area, where the average machinist is spending 8 hours a week creating manufacturing documentation.

Chart from “The 2014 State of Model Based Enterprise Report”, Lifecycle Insights

Chart from “The 2014 State of Model Based Enterprise Report”, Lifecycle Insights

The report also showed that 51% of suppliers or downstream consumers are requesting clarification of the documentation created, and 39% are experiencing scrap and rework in their manufacturing process resulting from misinterpretation of engineering documentation. The impact of poor documentation extends further, if manufacturers misinterpret a drawing, they troubleshoot the issues on the shop floor, which slows down production and results in scrap, waste, retooling, and frustration.

Chart from “The 2014 State of Model Based Enterprise Report”, Lifecycle Insights

Chart from “The 2014 State of Model Based Enterprise Report”, Lifecycle Insights

These findings make it easy to see how the productivity of the design process and manufacturing is suffering, along with the manufacturer’s bottom line, when designers and engineers spend their time creating, misinterpreting, and recreating technical documentation.

The author of the report sees that the consumers of 3D digital models need simpler ways to access this critical design data:“While the creation of 3D Annotated Models primarily falls to CAD applications, there is far more variety in terms of the software used to consume them. Interestingly, the variety of technologies used to view 3D Annotated Models reflects the one-to-many ratio of creators to consumers, where numerous consumers likely are not familiar with CAD applications and thus need something simpler, practical but imminently useful.”

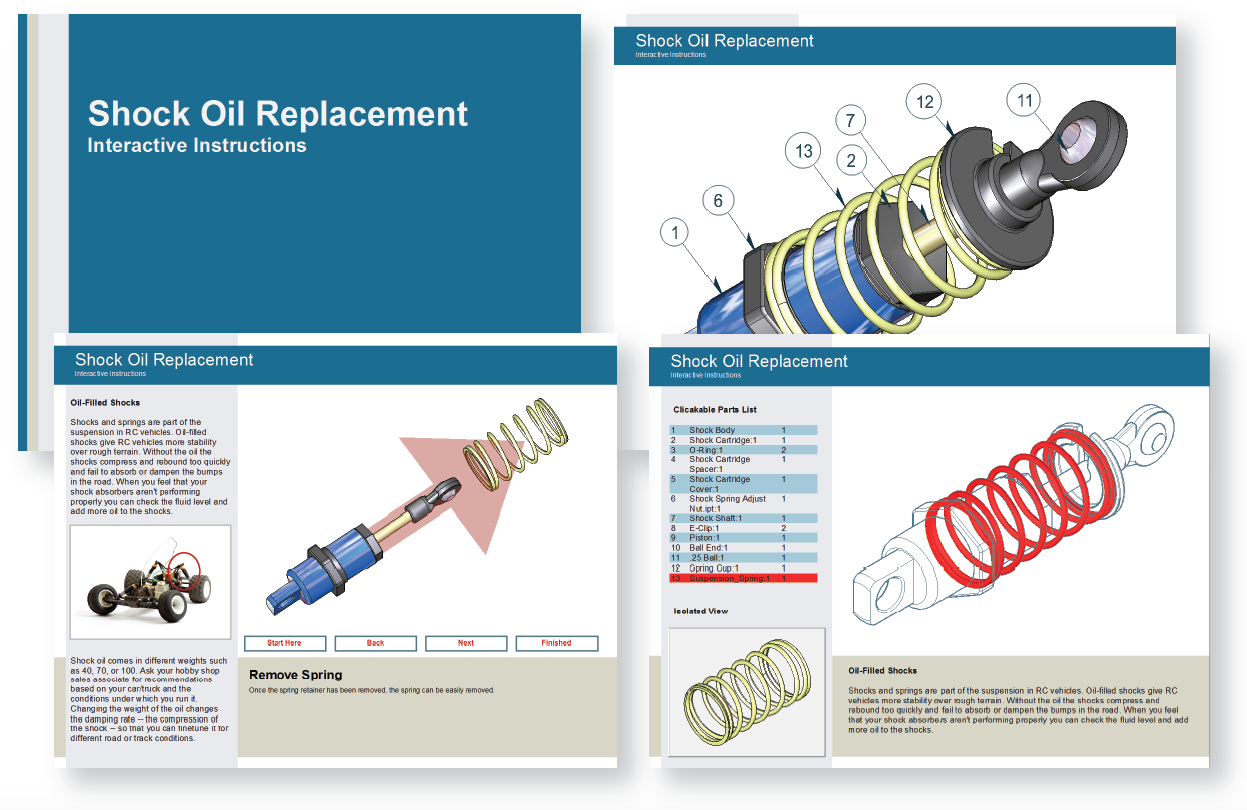

Fortunately tools are available today that make the process of creating technical documents smoother, faster, and error free, and that have the flexibility to create the documents in the digital formats that support Industry 4.0 and meet the needs of the specific consumer. For example, technical documentation programs like Pages3D and Publisher3D from QuadriSpace slash the amount of time it takes to create and publish technical documents in paper, web-based HTML, or PDF formats. Designers can quickly create technical illustrations from the original CAD files, without translations, and can perform the manipulations required to create the exploded part views that are needed to convey assembly and maintenance instructions.

QuadriSpace has partnered specifically with Solid Edge so that part and assembly models can be effortlessly used to create a wide variety of technical documentation.With these tools engineers can quickly and easily position Solid Edge files within technical documents or other files, create exploded views, parts lists, step-by-step procedures, and raster and vector technical illustrations.

Use your Solid Edge part and assembly models directly in Pages3D from QuadriSpace

Use your Solid Edge part and assembly models directly in Pages3D from QuadriSpace

With the close integration of Pages3D and Publisher3D with Solid Edge another benefit for designers is the ability to update entire documents or illustration sets when the 3D CAD files are modified or new revisions are created. The time savings for updating your technical documentation to reflect the latest design can be very significant. You can read a customer case study for how Soleras is using QuadriSpace software together with Solid Edge to create 3D interactive spare parts catalogs for the industrial equipment they manufacture.

So using these QuadriSpace software tools supports your move towards digital manufacturing and the Industry 4.0 revolution by enabling your digital models to be used directly to create all the technical documents you need.

Designers, imagine spending your time designing for a change, rather than converting and interpreting your work for others!

Manufacturers, these tools have the potential to significantly cut your rework, scrap, and downtime costs! Everybody wins!

Note: QuadriSpace and around 20 other partners will be demonstrating their software at Solid Edge University 2016 in October in Indianapolis, USA. This event is a great opportunity to talk with our software partners about how their applications can help you maximize the value of your Solid Edge design data!

Comments