From NC Pro to 3D Printer Novice

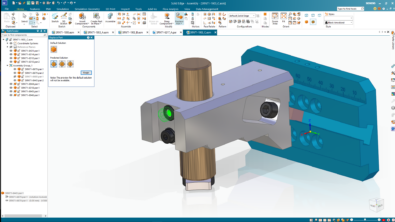

I am a machinist and CNC Programmer, and I like to refer to myself a “CAMologist”. My entire professional career has revolved around subtractive processes. I don’t use the word “expert” lightly, but if I don’t know what I’m doing in the CAM field by now, I never will.

When it comes to 3D Printing, I am a complete and utter novice. 3D Printing is beyond buzzword right now. It is a white hot field with lots of people advancing the technology. From 3D printed prosthetics to 3D printed houses to 3D printed metal nozzles to 3D printed wrenches in space to 3D printed cars, this technology is being applied everywhere.

The 3D printed car was done by Siemens partner Local Motors at the 2014 International Machine Tool Show (IMTS). I was at that show, and another 3D printer manufacturer caught my eye there.AirWolf 3D makes several different 3D printer models, and they feature larger-than-average print volumes. I have a curiosity about 3D printing, they have 3D printers; let’s get together!

Most CAM packages have a cutting technology that is very similar to how 3D printing works. In NX CAM, it is called Z-Level Milling. Other systems refer to it as Waterline Machining. At each cut level, a plane is passed through the solid body. The intersection curves between the solid and the plane represent the Cut Area for that level. The main difference between the two technologies is that in machining we are removing material to get to that shape, and 3D Printing is adding material to get to that shape.Another difference is Z-Level milling starts at the top and goes down, while 3D Printing starts at the bottom and moves up.

Can you teach an old dog new tricks? I plan to find out by educating myself on 3D printing. I have ordered an model HD printer and I will use it to teach myself about the technology. As I learn, I will post my progress here. In the meantime, if you have questions about 3D printing, post them in the comments below, and I will try to find the answers as I learn about this exciting technology. Here is a list of some of the questions I have right now:

- Why is a heated bed important for printing plastics?

- Why a glass bed?

- Is there a way to get rid of the visible lines from each layer of deposition?

- Does the 3D printed object shrink as it cools?

- Is there a way to incorporate inserts (like a threaded hole made from metal) in my 3D print?

- How can I 3D print an overhang (“undercut” in NC Machining terms)?

I also have a couple of ideas for projects to print, but I am open to your suggestions also.Stay tuned!

About the Author

| Jim Wright has a Master’s degree in Business Administration from the University of Central Missouri. He has over 30 years of experience in the manufacturing industry, and over 25 years of experience in the CAD/CAM field. He supports Siemens PLM CAM products. Prior to his current role, he held stints as CNC Programmer, Project Coordinator, CAD/CAM Department Manager, and CAD/CAM instructor for Siemens PLM. |

Comments