Solid Edge 2020 offers expanded MBD capabilities

Solid Edge 2020 introduces expanded capabilities to add MBD (model based defintion) information to your designs, and publish this information using interactive 3D PDF documents. Ricky Black presented these new capabilities at Realize Live today and explained how MBD can help you improve communications of your design with both your in-house manufacturing resources and with external manufacturers.

Ricky Black introducing Solid Edge MBD at Realize Live

Ricky Black introducing Solid Edge MBD at Realize Live

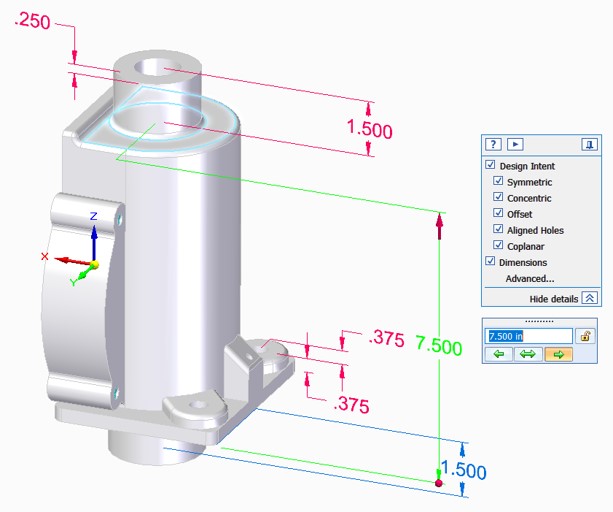

Solid Edge displays and uses 3D driving dimensionsSolid Edge has provided PMI (product and manufacturing information) to convey non-geometric data to downstream consumers of CAD models since its introduction in 2005. Examples of PMI include geometric dimensions and tolerances, 3D annotations (text), surface finish, section views and material specifications. In addition to displaying PMI in 2D CAD drawings, this information is also exported, and is immediately accessible, in Solid Edge portfolio solutions including Solid Edge CAM Pro and Solid Edge Technical Publications.

Solid Edge displays and uses 3D driving dimensionsSolid Edge has provided PMI (product and manufacturing information) to convey non-geometric data to downstream consumers of CAD models since its introduction in 2005. Examples of PMI include geometric dimensions and tolerances, 3D annotations (text), surface finish, section views and material specifications. In addition to displaying PMI in 2D CAD drawings, this information is also exported, and is immediately accessible, in Solid Edge portfolio solutions including Solid Edge CAM Pro and Solid Edge Technical Publications.

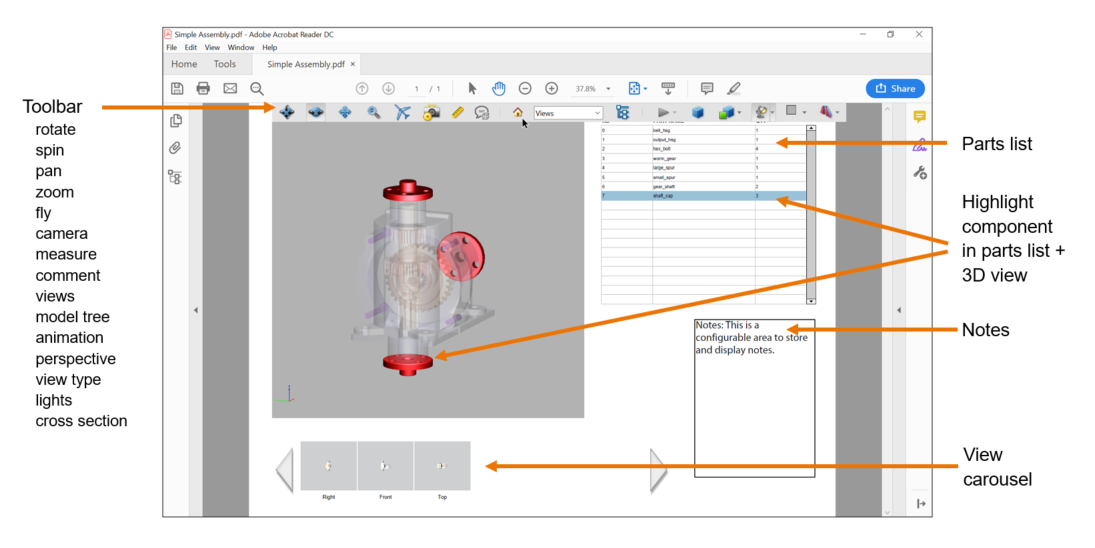

Solid Edge has also included capabilities that fall more into the area of MBD (model based definition). MBD is the practice of using 3D CAD models to fully define components and assemblies. The types of information included are similar to those listed above for PMI, but a key difference is that the information is captured and displayed around the 3D CAD model instead of being based around 2D CAD drawings. One example of existing MBD capabilities is the creation and display of dimensions that drive 3D Solid Edge models using synchronous technology. These dimensions are actually more than simple 3D annotations as they have the capability to drive the 3D geometry that they are linked to. Annotations placed on a 3D view New capabilities in Solid Edge 2020 include the ability to create annotations (for example surface finish symbols and parameters) that are associative to the surfaces that they define. These annotations can be exported to the STEP and JT formats and are also readable by manufacturing applications including Solid Edge CAM Pro. Solid Edge MBD accesses both user named and default model views. Another key capability is that users can create 3D PDF documents using user defined multi-sheet templates. These documents can include most Solid Edge geometry types including assemblies, wiring and cables, pipes frames, and multi-body parts. The resulting PDFs are interactive and include associative parts lists where you can select a part in the table and the corresponding part highlights in the graphics area. Selecting a part graphically highlights it in the parts list allowing easy verification of part numbers. 3D sections views can also be interactively created. Templates are created using the familiar Solid Edge Draft environment and can include 3D view windows, parts lists, notes, headers and logos. A “view carousel” window can be added to the template for easy selection of standard and user defined model views. One tip from Ricky is to use several standard model views (top, front, right etc.) to display MBD information and not try to place too many dimensions and annotations in a single ISO view.

Annotations placed on a 3D view New capabilities in Solid Edge 2020 include the ability to create annotations (for example surface finish symbols and parameters) that are associative to the surfaces that they define. These annotations can be exported to the STEP and JT formats and are also readable by manufacturing applications including Solid Edge CAM Pro. Solid Edge MBD accesses both user named and default model views. Another key capability is that users can create 3D PDF documents using user defined multi-sheet templates. These documents can include most Solid Edge geometry types including assemblies, wiring and cables, pipes frames, and multi-body parts. The resulting PDFs are interactive and include associative parts lists where you can select a part in the table and the corresponding part highlights in the graphics area. Selecting a part graphically highlights it in the parts list allowing easy verification of part numbers. 3D sections views can also be interactively created. Templates are created using the familiar Solid Edge Draft environment and can include 3D view windows, parts lists, notes, headers and logos. A “view carousel” window can be added to the template for easy selection of standard and user defined model views. One tip from Ricky is to use several standard model views (top, front, right etc.) to display MBD information and not try to place too many dimensions and annotations in a single ISO view. Viewing a Solid Edge Assembly using 3D PDF

Viewing a Solid Edge Assembly using 3D PDF

There are several published standards in the area of MBD including ASME Y14.41-2012, ISO 16792:2015 and MIL-STD-31000B from the United States Department of Defense. Solid Edge MBD can help you move towards compliance with these standards that are increasingly requested by customers in the Aerospace and Defense, and Automotive industries.

Solid Edge MBD will be made available in Q3 2019 as an add-on module (SE446N/F). The capabilities that you have today in the standard Solid Edge modules for PMI creation and model view creation will continue to be available and enhanced in these standard modules. The Solid Edge MBD module adds the capabilities for 3D drawing creation and 3D PDF publishing.

These MBD capabilities will continue to develop and we welcome input from our users on what additional capabilities they would like to see. Please let us know what requirements you are seeing in your company for MBD and how the existing and new capabilities in Solid Edge are helping you to meet these needs!

Comments