MBD Tools in Solid Edge

Are you part of an organization which does not believe in saving time, money and energy in particular or resources in general? sounds freakish, right? You can easily tell if this is happening around when you see traditions being followed blindly without querying or supported with reasons. These traditions gradually metamorphose into superstitions.

When it comes to handling engineering design data, especially the way it is shared around during its lifecycle spanning various departments like Design where it originates, necessarily in a 3D format these days, through manufacturing, inspection, procurement, suppliers, services, etc. why linger in age old traditions of creating flat 2D drawings ?

2D drawings are merely multiple interpretations of a single source of truth which originated as a 3D model. Why not share the data in its original form i.e. in the 3D format. This is the essence of MBD or Model Based Definition.

With this blog post I do not intend to pitch for MBD nor get into the pros or cons of embracing it. If your organization has already adopted Model Based Definitions this article is for you. Those who have just started to getting your feet wet, read the small prolog and continue with the overview of the full range of tools and features that Solid Edge provides for enabling MBD within your organization.

- Prolog

- Creation

- Delivery

- Enabler

- Management

- Epilog

Prolog

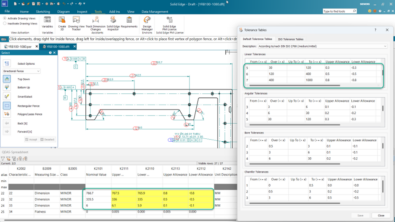

MBD is a mechanical engineering initiative where a 3D model with regular dimensions along withProduct Manufacturing Information (PMI) augments or replaces a 2D engineering drawing as design documentation. PMI is not new in Solid Edge. It is composed of non-geometric information that describes a design, including geometric dimensioning and tolerancing symbols, surface finish symbols, material and procedural information for e.g. surface treatment and more.

At the heart of MBD is the idea of dimensioning features and 3D geometry instead of flattened lines, arcs or circles and Solid Edge has a tab on the ribbon bar dedicated to PMI which hosts an entire gamut of tools required to fully define a 3D model. This prepares and gets you ready to embrace the MBD movement which is fast gaining momentum across industries.

Creation

The Smart Dimension is a multi-purpose command. It can place dimensions in 3D space. The Smart Dimension can pick 3D edges on the models and also feature faces as shown in the animation below. The Smart Dimension tool works equally well on imported dumb geometry.

Note that this being 3D space, the N key plays and important role in orienting the placed dimension in various orientations. Solid Edge also helps by auto-orienting the dimension when you change the view which is also illustrated in the later part of the GIF above.

Additionally, any planar face or reference plane can be used to lock the dimension in that plane. This option is available on the Command Bar of the Smart Dimension command.

Besides this, an overwhelming number of commands and features on the Annotations tab let you create various PMI and GD&T symbols like Callouts, Balloons, Surface Texture Symbols, Weld Symbols, Edge Conditions, Feature Control Frames, Datum Frame, Datum Target and Leaders.

Solid Edge PMI [Image from video by Krzysztof Gad]

![]() Tip: You can increase the PMI size by using Ctrl+Shift+. decrease it using Ctrl+Shift+, or from the buttons in the PMI tab on the ribbon bar. Section Views can also be created.

Tip: You can increase the PMI size by using Ctrl+Shift+. decrease it using Ctrl+Shift+, or from the buttons in the PMI tab on the ribbon bar. Section Views can also be created.

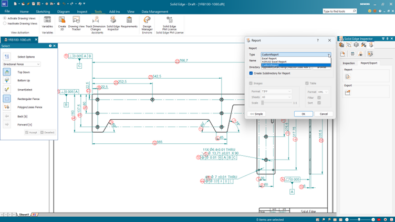

Delivery – Although the PDF format has fast and convincingly established itself as the de facto standard for document sharing including 3D CAD formats, it is important to remember that Solid Edge also has its own SEV format which is ideal for viewing on a mobile device. I haven’t had enough opportunity to explore this format so let’s stick to PDF for now.

The MBD creation stage is a means to an end and not an end in itself. It further needs to be delivered across various segments of the organization for consumption, most importantly in manufacturing and inspection.

From within Solid Edge, simply Save As the 3D model in the part, assembly or the sheetmetal environments and select the 3D Adobe Acrobat Document as the format. When used for viewing, the Adobe Acrobat Reader XI furnishes a mind-boggling set of tools and features for viewing, measuring and manipulating the 3D model.

Right off the bat, right-click in an empty space inside the PDF and from the context menu ask to show the toolbar.

On the toolbar, click the Toggle Model Tree button to display the side bar. This completes the process of opening up access to all facilities that the Adobe reader has for 3D model viewing and manipulation.

The most prominent ones are the 3D Measurement tool, Add 3D Comment tool and the Cross Section tool. These together form the meaty part of the entire MBD handling withing the viewer.

Other cosmetic and equally interesting tools are the various display modes which outnumber those available in Solid Edge itself, transparency, orthographic/perspective modes, various eye-candy lighting modes and lastly some novel viewing methods like spinning and flying around the model.

Together these help organize the rich MBD data into clean and structured 3D presentations with different view and display settings.

![]() Tip: Named Views from Solid Edge show up in the Views list box on the View toolbar in Adobe Acrobat XI viewer.

Tip: Named Views from Solid Edge show up in the Views list box on the View toolbar in Adobe Acrobat XI viewer.

MDB Enabler – The MBD ecosystem is not complete without having a reliable physical ‘vehicle of delivery’ on the shop floor. Nothing can match the convenience of a hand-held mobile device which is both robust and can be used easily in a treacherous environment like the production floor. Siemens PLM has worked closely with Microsoft in this area to amalgamate the best of hardware and cutting edge software for use in the CAD domain. This benefits MBD immensely.

In this video you can see small business owner, industrial designer and legendary Solid Edge user Bob Mileti using a Surface Pro right in the middle of his shop floor along with colleagues discussing about the design from the 3D model directly. No paper drawings spread all over, no clutter, just fast and easy design data dissemination and subsequent production.

MBD Management – This is a no brainer if your organization is already using a PLM system. At the very least Solid Edge provides a brilliant set of Data Management commands which are inbuilt into the product. Once again an entire tab on the ribbon bar is dedicated for this purpose. If you have been managing drawings this way, it will take care of your MBD enabled documents equally well. No breaking traditions here.

Before we conclude, it is also important to note that MBD is not strictly 3D-only. There are organizations who have taken a middle path of including both the 3D model and its associated 2D drawing for various reasons that are unique to their requirements.

New In Solid Edge ST10 in this regard is that “PMI retrieved in a drawing are fully associative. This means you can really put the intelligence in the model if you like – if you put in tolerance in the model and treat it as the master and later change the tolerance, the dimension in the draft will update. This is pretty nice for those of you trying to get to more of an MBD (Model Based Definition) approach to things, where all the intelligence is in the model” informs Dan Staples, Vice President, Mainstream Engineering at Siemens PLM Software in his recent reply to a post on the Solid Edge discussion forum.

New In Solid Edge ST10 in this regard is that “PMI retrieved in a drawing are fully associative. This means you can really put the intelligence in the model if you like – if you put in tolerance in the model and treat it as the master and later change the tolerance, the dimension in the draft will update. This is pretty nice for those of you trying to get to more of an MBD (Model Based Definition) approach to things, where all the intelligence is in the model” informs Dan Staples, Vice President, Mainstream Engineering at Siemens PLM Software in his recent reply to a post on the Solid Edge discussion forum.

Epilog – It is evident that Siemens PLM has left no stone unturned in building up an entire ecosystem that will facilitate rolling out MBD in your organization by way of providing all the necessary tools for its creation, delivery, enabling and lifecycle management. Be it a paperless initiative or a contractual obligation, the time to embrace MBD is now.

~Tushar Suradkar

Solid Edge Users Facebook Group – Let’s Sync

Solid Edge Users Facebook Group – Let’s Sync

Comments