Getting started with simulation as an SMB

In an era where the design and manufacturing of products are characterized by increasing complexity, small to medium-sized businesses (SMBs) face an uphill battle. The integration of diverse systems such as mechanical, electronic, electrical, and software components into a cohesive product demands not only a high degree of collaboration and iteration but also a rigorous testing protocol to bring quality products to market. This multifaceted challenge requires SMBs to optimize their engineering processes with simulation to maintain a competitive edge.

Leveraging speed for competitive advantage

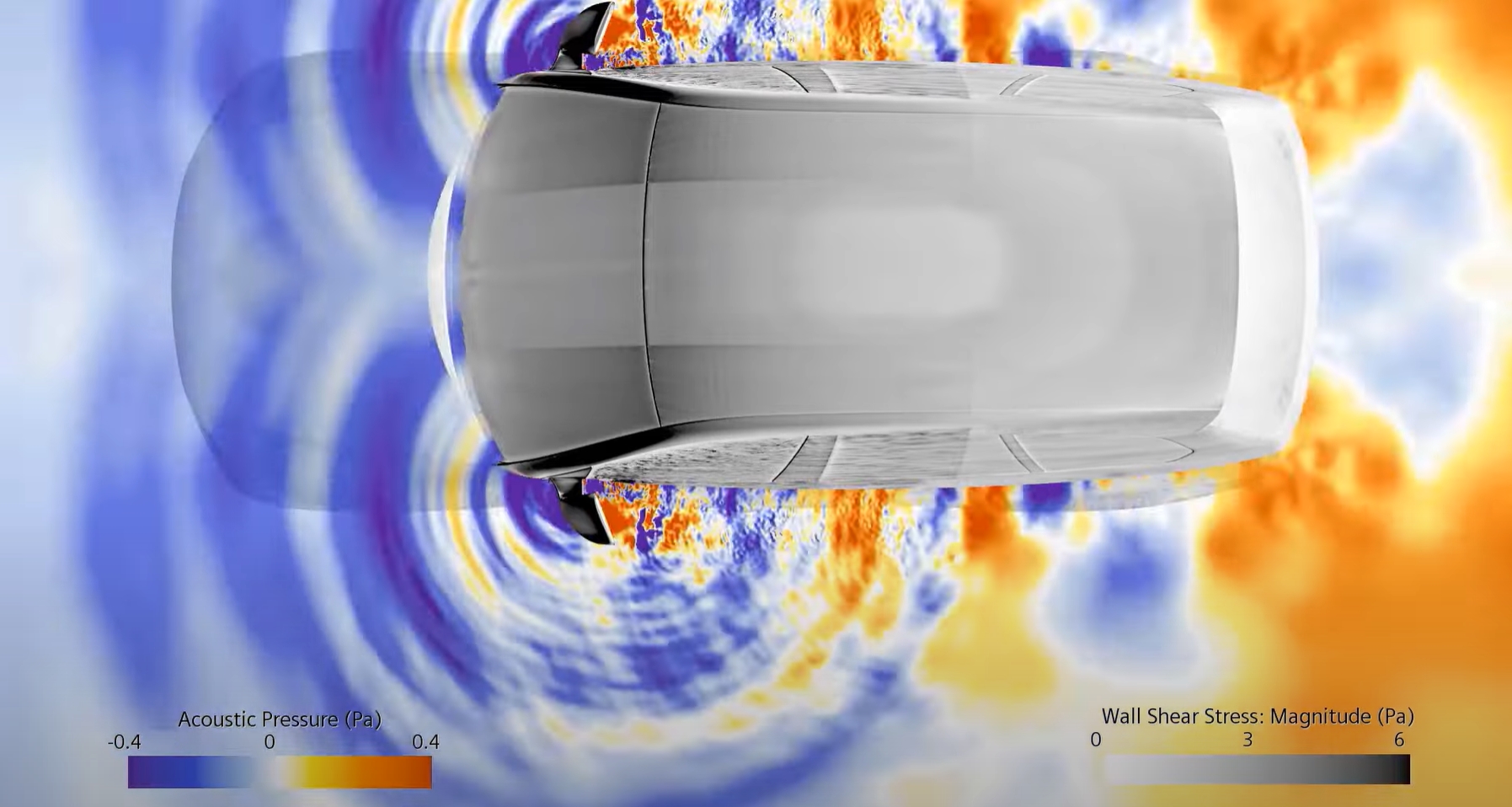

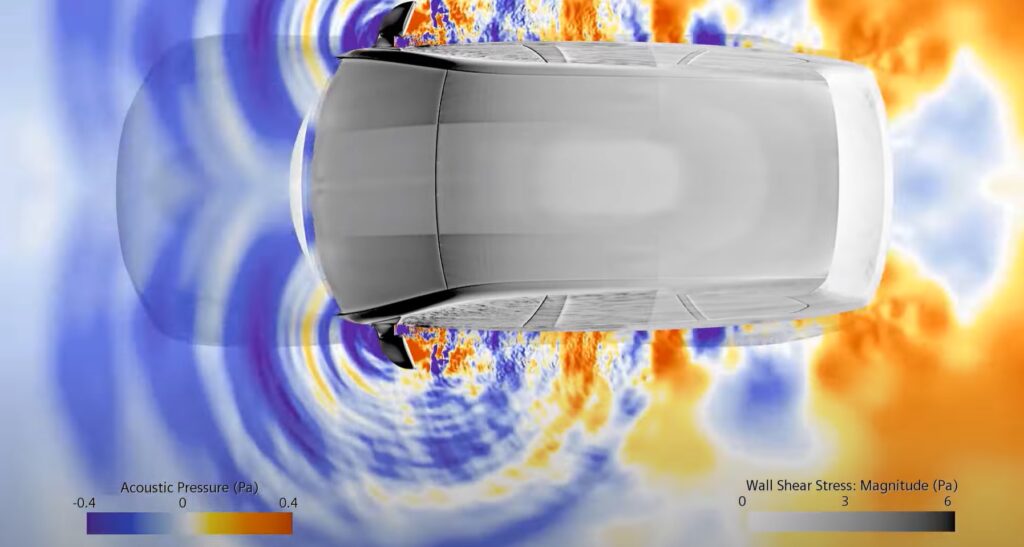

Timeliness in a new product development strategy is a critical factor that can significantly impact the success of a product. For SMBs, the ability to fast-track product development without compromising quality is a strategic advantage that is easier than ever with an integrated design process. Now, aligning rapid development with evolving consumer expectations and maintaining quality is possible with software like Simcenter STAR-CCM+ and Testlab. This is where the integration of advanced technologies like computational fluid dynamics (CFD) simulation comes into play, offering a solution to accelerate the design and development lifecycle efficiently.

Cost management and efficiency with simulation

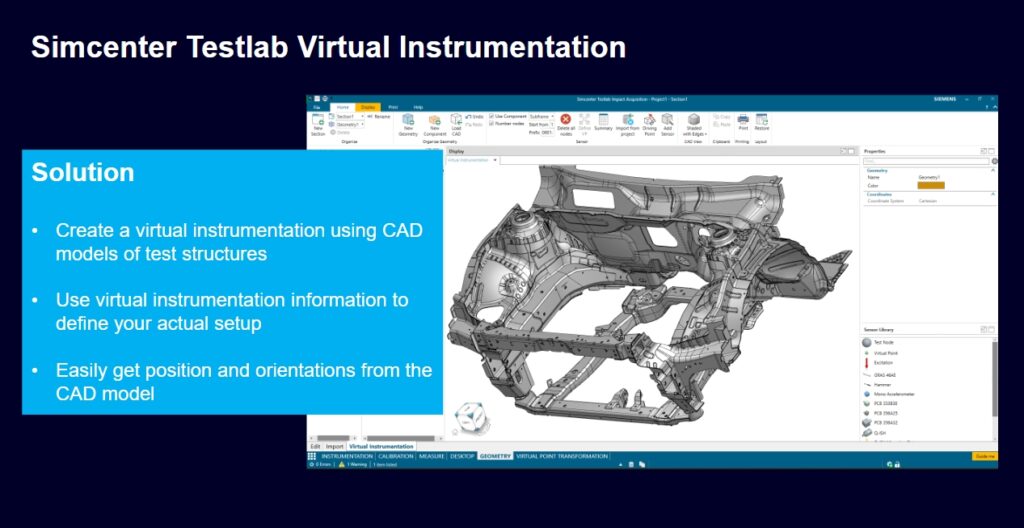

The adoption of simulation has marked a pivotal shift in how SMBs approach product development. By moving away from the traditional reliance on physical prototypes, which are both costly and time-consuming, SMBs can now utilize digital simulations to expedite the testing phase. This shift not only significantly reduces the material and labor costs associated with physical testing but also enables a more comprehensive analysis of the product design through virtual sensors and digital twins. This degree of simulation can analyze performance parameters without the limitations of physical prototype testing. By providing quick and reliable data, simulation allows for rapid iterations and decision-making, which in turn, shortens the time to market. This efficiency does not come at the expense of product quality; on the contrary, it ensures products meet high standards of performance and reliability.

The Strategic Imperative for SMBs

The integration of simulation technologies into the engineering workflow is not merely a tactical move but a strategic imperative for SMBs looking to thrive in a competitive landscape. This approach not only tackles the immediate challenges of cost, quality, and speed but also sets the foundation for sustained innovation and growth. As the market conditions evolve, the ability to quickly adapt and respond to new demands is crucial.

How SMBs can start with simulation

Siemens offers an array of simulation products that range from product validation to physical testing. For SMBs we encourage you to start with Simcenter Testlab for physical data collection, analytics and modeling. Or you can get started with our CFD offering, Simcenter STAR-CCM+ where you’ll find everything in a single unified software. Simcenter STAR-CCM+ includes pre-processing via meshing through multiphysics modeling, data analysis and photorealistic visualization and VR.

Check out our hub page to learn more.

About the author

David Lyell is a Siemens Digital Industries Software marketing manager and serves the Small and Medium Business industry. He has worked in manufacturing and marketing across several industries, including automation, job shops, additive manufacturing and woodworking.