Corporate

Avoiding rework in electronics design with earlier requirements verification

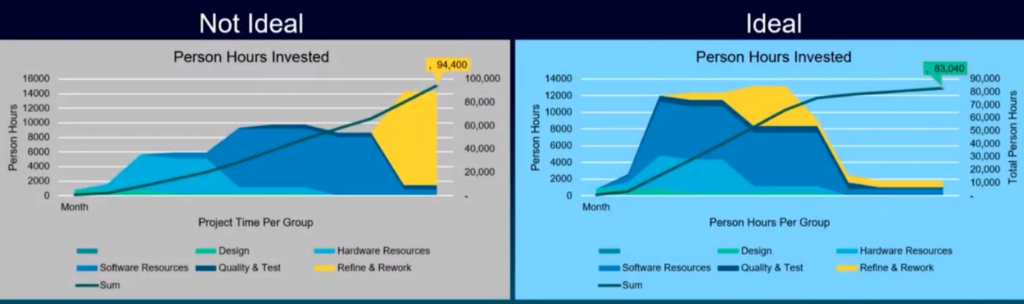

When electronics manufacturers can validate and verify the design and development of products sooner in the design process, they avoid higher costs required with refinement and rework. But how do manufacturers move validation and verification earlier in the design process?

Using ALM for comprehensive cross-team, project and system workflows

With concurrent product design, the collaboration between disciplines can happen at any design phase. This concurrent process leverages a unified lifecycle solution that naturally shifts the requirements and verification earlier in the design process, as shown below.

This helps to avoid rework in later design stages by:

- Improving speed with an integrated system linking requirements to manufacturing

- Reducing non-value add tasks with unified and planned requirement and verification workflows

- Decreasing repetitive work by reusing templates and collections of requirements

Learn more about shifting left and how electronics manufacturers can use ALM for requirements management and traceability.