Response Surface and Sequential Optimisation of a Heatsink Using FloTHERM. Part 6 – Response Surface Models

So far we’ve looked at a couple of ways to optimise the design of a heatsink to meet some quantified design goal. Any such approach entails exercising a design by modifying some parameters that define it and using simulation to see what the effect is. By doing this one builds up a relationship between the outputs of a design (e.g. temperature) and its inputs (e.g. geometric parameters ). Although such Output=f(Inputs) insights can be used for optimsation, such an equation is, by its nature, a model of the system. A very fast model from a prediction perspective.

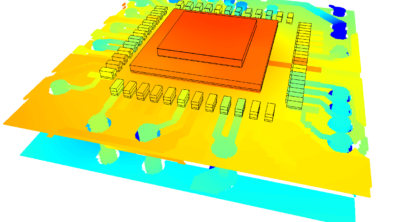

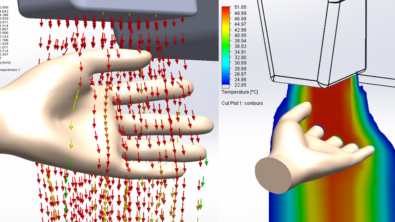

“Scientific modelling is a scientific activity, the aim of which is to make a particular part or feature of the world easier to understand, define, quantify, visualize, or simulate” (Wikipedia). All modelling is a form of abstraction; taking reality, representing it, condensing it, reducing it to something simple and useful. In this case our response surface is the model (Response Surface Model: RSM). The response surface relates a component temperature to various investigated design parameters:

Component Temperature =f(TIM2 resistance, heatsink base thickness, heatsink fin height, number of heatsink fins, fin width)

OK, sure, effectively just a fancy 5 dimensional lookup table. FloTHERM uses either a 2nd order polynomial or Kriging method to relate the output to the inputs, automatically selecting which ever method produces the most accurate response surface fit. The RSM can be inspected using a simple spreadsheet interface, pointed at the FloTHERM response surface file that is created:

The input values can be modified then the resulting change in output(s) seen instantaneously. The lower and upper bounds of the input parameters used to define the DoE extents are shown. Although the model is only valid to the indicated accuracy within those bounds, outputs can be shown for out of bound inputs. Used at your own risk. Interpolation will always be the more dependable cousin to extrapolation.

Using a numerically simulated response surface is kind of like a two stage abstraction. FloTHERM (3D CFD numerical modelling) is used to generate behavioural data that is then collapsed down into a RSM. Who knows, maybe this could be a future of simulation. Performing a series of heavy weight 3D simulations to extract a RSM that is capable of instantaneous prediction. Simulation can never be fast enough, but such a technology might possibly get us closer to a real-time simulation holy grail.

3rd May 2016, Ross-on-Wye.