Why focusing on ICE thermal management to reach emission regulation targets?

Innovating conventional powertrain design

“The European automotive industry invests more than €50 billion in R&D annually, a large percentage of which goes towards fuel-efficiency technologies, to meet EU CO2 emission reduction targets thereby complying with NOx and soot standards. However, very few are likely to be able to change the makeup of their fleets fast enough to meet the immediate challenge of the 2021 EU CO₂ emission reduction targets and avoid the significant fines for missing them.” Source: The CO₂ emissions challenge: some carmakers are running late in the race to 2021 – PA Consulting report.

Consequently, to achieve future regulations OEMs and suppliers must innovate in their conventional powertrain design and at the same time come up with competitive alternative propulsion systems as soon as possible. Nevertheless, innovation in conventional powertrains in many instances implies an increase of technology complexity while alternative technologies imply an immediate need of removing uncertainty through rapid system development.

Either way, ideally, what OEMs and suppliers would need is to equip themselves with the best engineering tools to accelerate the transformation. That’s a challenge we at Siemens Digital Industries Software accept: we provide a set of simulation solutions to make virtual design and evaluation of new innovative idea real.

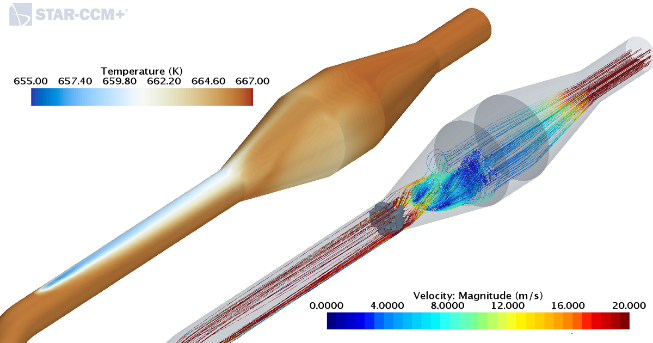

One of the specific innovation areas where OEMs and suppliers can focus on is the thermal management of the internal engine combustion system. Optimizing thermal management of an after-treatment system is really a challenge. Indeed, for maximum efficiency (and so satisfying emission rate) after-treatment systems such as catalysts require specific temperatures to operate efficiently. Using CFD simulation is a way to do a detailed thermal analysis and assess the best powertrain architecture.

Optimizing thermal management in modern powertrains using CFD simulation

This webinar “Optimizing thermal management in modern powertrains using CFD simulation” is co-hosted by Carlo Locci – simulation powertrain application specialist. Carlo showcases how using our CFD simulation tool Simcenter STAR-CCM+ support the thermal management modeling of your engine, and introduces:

- An innovative technique to predict the thermal interaction between the fluid film and the wall in an SCR. This technique was developed to allow for long transient runs in a Selective Catalytic Reduction (SCR),

- The most recent developments in this field of Conjugate Heat Transfer (CHT) related to Powertrain problems,

- Perspectives on heat production modeling for fuel cells.

If you are eager to know more about our whole Simcenter portfolio for powertrain applications listen to Warren Seeley – Simcenter Director of Powertrain- who gives the webinar introduction.

- Register here to access the online webinar: Optimizing thermal management in modern powertrains using CFD simulation

- More information on our website: Engineer innovation with CFD- focused Multiphysics simulation webpage