Top ten best innovations engineered with Simcenter

“The road to heaven is paved with good innovations” – Unknown

Innovation is technology’s most important word today. Innovation is also technology’s most overused word today.

Just google ‘Is innovation overused?’. Endless results. Somewhere along the way, the word ‘innovation’ became less about breakthroughs and more of a buzzword. In this blog, we put the focus back on the ‘breakthroughs’. Today, we put the spotlight on some truly innovative products that make life better.

Last week, I read an article on ‘Ten amazing product development innovations of the 2010s‘. Inspired by this, I have compiled my own personal list of top ten best innovations engineered by Simcenter customers.

There were only three criteria:

- The innovation must be incremental, disruptive, architectural or radical

- The contenders must be featured on the Siemens Customer Success site (Our customers bring 100s of innovative products to life but not all of them are shared publicly)

- The product design must involve tools from the Simcenter portfolio

To pick my contenders, I read through dozens of Simcenter customer stories. Don’t judge. It’s a pandemic and there isn’t much to do other than stay home, stay safe and read.

Here is my personal list of top ten best innovations from our customers using Simcenter products:

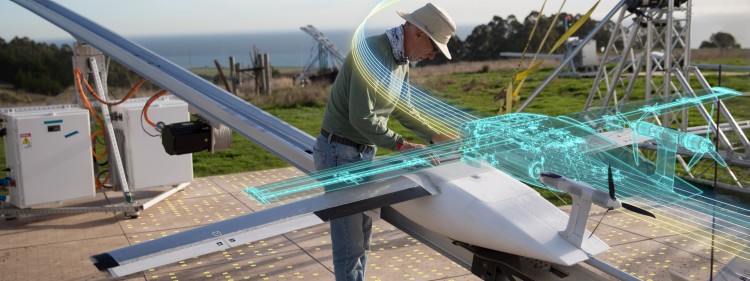

1. Lifesaving medical drones – Zipline

Someone in rural Rwanda needs blood. Time is running out. The nearest hospital is 50 miles away. But help is on the way soon. A Zipline drone flies in dropping its cargo by parachute. A box with essential medical supplies like blood and vaccines is delivered. All within thirty minutes.

What sounds like a feel-good Hollywood story is a real-life example of technology improving human life. The battery-powered drones from Zipline have delivered an estimated 47,000 lifesaving medical deliveries in Central Africa. The drones, capable of 100 kmph and a range of 80 kms, can deliver cargo up to 1.75 kg. With NX and Simcenter, Zipline accelerated the drone development, helping cut weight and improve the battery thermal performance with a digital twin. From engineering innovation to engineering life, truly an incredible product.

Story: Lifesaving drones designed with CAD software

Video: Digitalization and drones transform medical supply delivery

2. Street theatre machines – La Machine

Next on the list are the insanely whimsical and outrageous moving machines from La Machine, a la Mad Max. Giant mechanical spiders, minotaurs and elephants galore, the 20 year old French street theater company uses movement to thrill, excite and inspire their audience with never-seen before creations.

The machines are a celebration of life and hundreds of locals and tourists line up to experience them everyday. Using Simcenter, La Machine ensures the structural integrity and performance of their machines digitally to make sure they are safe in operation. Motion, music, mechanics and utter madness – La Machine is an experience.

Story: La Machine sets its creations into motion using Simcenter Femap and Simcenter Nastran

3. Flying river taxis – Seabubbles

“Hey! I’m taking the bubble. See you in ten minutes” – You could be uttering these words pretty soon, thanks to French startup Seabubbles. The creation of legendary French yachtsman Alain Thebault, these flying water taxis will soon redefine urban transport. An uber-cool cross between a plane, car and boat, Seabubbles is all electric, zero emissions and zero noise and can run for four hours.

Think of it as the new Uber. Except you’re on water waving at everyone stuck in traffic on land. Using Simcenter, Seabubbles and Caponetto-Hueber, a marine design consultancy, optimized the performance digitally with computational fluid dynamics (CFD) simulations and went from concept to river trials in six months. Heck, I’d happily move to Los Angeles now if I can avoid the snarling traffic and take the ‘bubble’ from Malibu to Newport Beach.

Story: Flying through the city: Seabubbles taxi designed using Simcenter

Video: How to navigate waters digitally

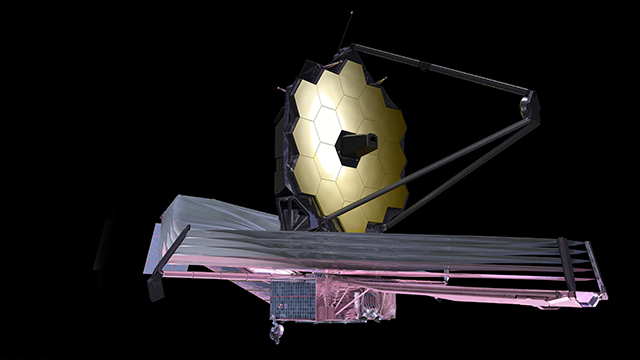

4. James Webb Space Telescope – NASA

The largest, most powerful and complex telescope ever built. Technological marvels don’t get better than the James Webb Space Telescope (JSWT) from NASA. The size of a Boeing 737, this telescope is humanity’s greatest invention yet to answer the ever-present existential questions – How did the earliest galaxies assemble? What can we learn from the birth of the first stars? Are there more of us out there?

The telescope’s data sheet reads like a collection of the world’s most incredible facts. It can detect a bumblebee’s heat signature at the distance of the moon, fold like an origami sheet inside a rocket, is 100 times more powerful than the Hubble telescope and can peer back 13.5 billion light years. The JWST is a one shot mission, only one opportunity to successfully launch and deploy. An army of Siemens tools – NX, Teamcenter, Tanner design suite, Simcenter – all contributed to ensuring every part of the telescope’s performance is thoroughly tested digitally before deployment. The telescope has also spawned a mini-invention factory – microshutters, sunshield materials, infrared detectors are some of the new inventions that are part of the telescope.

Story: Software is key for deep space exploration

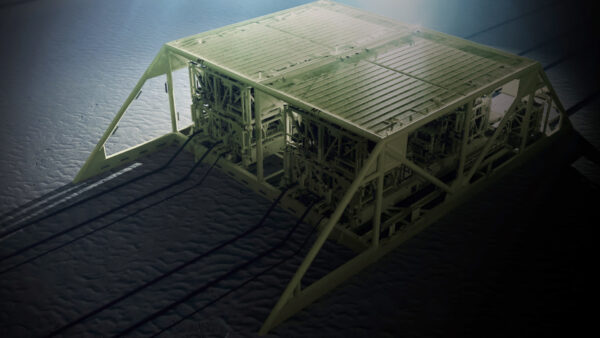

5. Åsgard subsea gas compression – Aker Solutions

From deep space to deep sea, next is the world’s first subsea gas compression system from Aker Solutions and Equinor. The size of a football field on the ocean floor and weighing 12,00 tons, the system has lower CO2 emissions, higher efficiency, increased recovery rate and lower operating costs – all by putting the compressor near the wellheads.

The system delivers an additional 282 million barrels of oil – that’s enough energy to power all homes in the United Kingdom for an entire year. Multiphase CFD simulations with Simcenter helped the team to design and validate the flow of gas and liquid through the system digitally. By accurately simulating what happens 300 feet below sea level, the team also extended the life of the Åsgard subsea gas compression system.

Video: Multiphase flow simulation to support Asgard field life extension

Video: Driving digital transformation using CFD with Simcenter

6. Smart delivery droid – TwinswHeel

Automating the last mile of delivery is the next big challenge in online shopping and delivery. Amazon is thinking drones. TwinswHeel meanwhile have borrowed inspiration from Star Wars. Their smart delivery droid, unlike its Star Wars counterparts – R2-D2 & BB-8, might start a ‘store wars’ soon.

Already in trial by stores and supermarkets, the droids can move with or without an operator. With Simcenter, TwinswHeel created a digital twin of the droid systems to virtually analyze every safety scenario. The droid has met the same safety requirements mandated by autonomous vehicle regulations and certification standards. The future of logistics (and every Star Wars fan’s personal pipe-dream) is now here.

Video: Powering autonomous mobility for a smart delivery droid using Simcenter

Story: Droid delivery manufacturer uses Simcenter software to validate advanced safety mechanisms

7. Aerofoil – Williams Advanced Engineering

Staying with supermarkets, this next innovation is a personal favorite. The idea of Formula 1 wings in a supermarket fridge is bonkers. Except it’s not. Because aerodynamics! Williams Advanced Engineering, the multiple award-winning technology and services arm of the Williams Group, along with UK startup Aerofoil Energy have developed the innovative device by borrowing from the aerodynamic devices on their F1 cars.

More than 50% of supermarket energy consumption comes from the open-end refrigerators. The Aerofoil stops cold-air from spilling out on to the aisle and saves up to 30% of a supermarket’s energy costs. Today, more than a million aerofoils have been installed in over 3500 stores in 10 countries, avoiding 165 million kgs of CO2 emissions every year and reducing electricity bills. A device like this had never existed, so the engineers used CFD simulations with Simcenter to virtually design and test the performance of the Aerofoil.

Video: Williams takes F1 wings to refrigerators with Simcenter

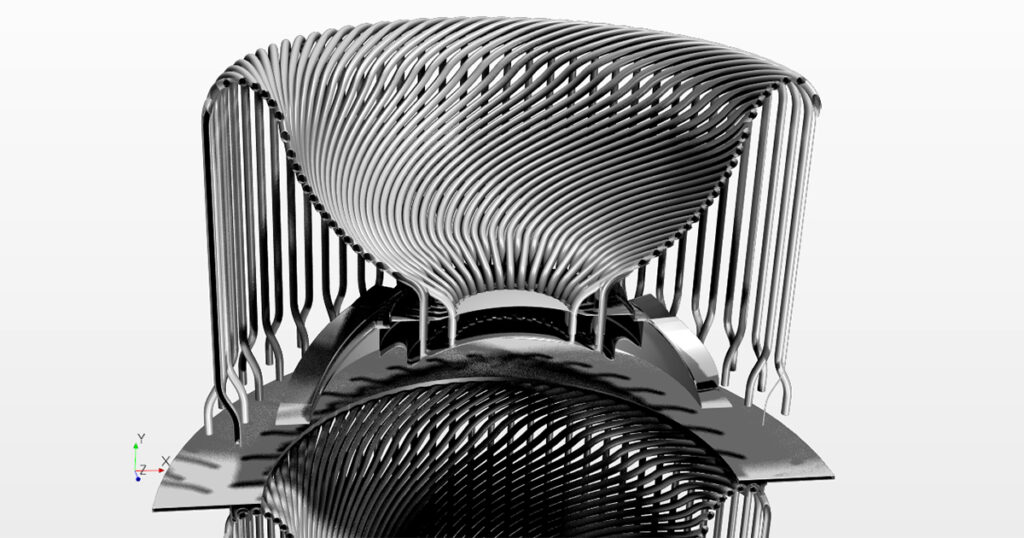

8. Vuilleumier cycle heat pump – ThermoLift

Ranked No.1 by the US Department of Energy for the best energy saving potential for commercial HVAC systems, ThermoLift have caused quite a stir in the energy industry. The innovative generation 1.0 system is a natural gas driven air conditioner and heat pump. Imagine replacing your building heating, cooling and hot water systems all with a single appliance? With ThermoLift, your imagination can now become reality.

The device can deliver 30-50% reduction in energy costs and reduced greenhouse gas emissions. With no refrigerants and a hydrogen/solar plan for future variants, ThermoLift is a game-changing technology with a big role to play in our energy future. Partnering with Simcenter Engineering Services, the ThermoLift team utilized digital simulation and design exploration in Simcenter to evaluate multiple designs and find the most efficient one while reducing costs and emissions.

9. Wearable micro-pump drug delivery – Sensile Medical AG

The patented SenseCore Technology from Sensile Medical is brilliant in its simplicity. It’s a micro rotary pump with only two plastic parts – a housing and a rotary pump shaft. The technology is currently in market to treat Parkinson’s disease. Easily wearable, the micro device is personally programmable to the patient, ensuring the exact dosage of drug delivery at the touch of a button. And the best part? There are no dosage calculations and the patient doesn’t even see the needle.

The Swedish startup relies on tools from Siemens Digital Industries Software – NX, Teamcenter, Simcenter, Solid Edge – to create an end-to-end innovation platform from design to analysis to data management. Next up for SenseCore? Diabetes treatment.

Story: Successful growth with end-to-end innovation platform

10. Wärtsilä 31 4-stroke engine – Wärtsilä

Rounding out the top ten is the world’s most efficient 4-stroke diesel engine. It’s so efficient they made it Guinness World Records official. The diesel fuel consumption from the engine is as low as 165 g/kWh, significantly lower than any other similar engine on the planet. With an expected lifetime of 40 years and emissions lowered as much as 50%, the engine comes in both gas and diesel models and complies with all the latest emission regulations.

From ideation to concept to design, Simcenter and NX were used to optimize the performance of the complete engine system. With an engine digital twin, Wärtsilä simulated and improved every component, all of which together delivered the world’s most efficient engine. If today’s shipping emissions were a country, it would rank sixth in greenhouse gas emissions. The improved fuel efficiency and reduced environmental impact from 10. Wärtsilä 31 will play an immediate role in reducing shipping emissions.

Story: Wärtsilä deploys Simcenter tools to build a high-efficiency engine

These are just my personal favorites from our publicly available customer stories. There are many other important innovations being delivered today by our customers with Simcenter.

If you have used Simcenter to bring out an innovative product to market, do let us know. This might just become an annual list.

Till then,

Keep engineering. Keep innovating.