Simulation Automation

There’s no doubt about it: simulation is delivering value in product development.

Some are avoiding multiple rounds of prototypes. Some are reducing the cost of goods in products. Some are making designs both lighter and stronger simultaneously. Some are coming up with more innovative designs that work functionally. Overall, many companies are reaping the benefits of applying simulation early and throughout the design cycle. And if there are any issues with simulation, it’s that managers seem to want more.

So how can an engineering team get more productivity out of their analysis tools? One clear answer is automation. It removes repetitive tasks from users hands, allowing them to concentrate on the value-added aspect of simulation. It also promotes standard best practices across a company. Here are some capabilities that do just that.

Macros

One of the most simple, yet valuable, ways to automate a simulation process is to leverage macros.

The idea is straightforward. A user can record a sequence of user interface interactions, such as selecting menu options or entering values. This sequence of actions is then mapped to a trigger, often a specific combination of keyboard keys or mouse buttons. Then, whenever the users want to initiate that sequence of actions, they simply hit the trigger.

This approach provides the most value when applying repeated actions within the same model. It reduces repetitive work for the user. However, it also eliminates any potential human error likely to occur in a heavily repeated action. Furthermore, executing macros happens very quickly, far faster than the sequence of actions could be executed by hand. Lastly, macros are an opportunity to apply analysis standards across a company.

In all, macros allow users to avoid repetitive work, reduce human error, accelerate their simulation processes, and distribute analysis standards.

Templates

Where macros automate repetitive tasks within a simulation model, analysis templates automate entire sets of tasks by offering an accelerated starting point.

Analysis model templates include standards that should be included in all simulations of that type. For some cases, a template might include a parametric model of a pump that has already been meshed to the correct level of detail. For other cases, a template might include standard loading cases based on data collected from physical tests. For yet others, a template might encompass all of the standard materials and their properties that are officially approved by a company.

Templates, however, do not just apply to entire models. Loads and boundary conditions can be applied as templates. Solver selections, method selections, and their corresponding parameters might be included in a template.

The value in templates is also straightforward. Templates simply allow users to avoid creating everything from scratch. They start their process several steps farther than a clean sheet. But just as importantly, templates are another way to distribute best and standard practices within a company.

Simulation Workflows

A different kind of automation builds on top of templates. Simulation workflows apply the concept of workflows to simulation.

The idea here is that each analysis template requires several inputs to be run. Once those are provided, the simulation can be solved, producing a number of outputs. With simulation workflows, the outputs from one analysis is fed as inputs to another analysis. This chain of simulations can be used to connect disparate types of engineering physics that are interrelated. For example, a fluids dynamics analysis of a wing would yield loads that are then passed on to a structural analysis of the internal stringers. In another example, a complex combustion analysis of a turbine engine would pass temperature fields to a structural analysis of a turbine blade.

Such simulation workflows can be used to automate very complicated analyses, but they can also provide guidance to novice users as well. They simply ask for standard inputs and produce standard outputs that can be interpreted.

The value here is more advanced than in other cases. Expert users can automate an entire complex simulation process. Novice users get guidance on how to complete a range of analyses, ranging from the simplest to incredibly complex. Both use cases deliver value.

Application Extensions

The last, but not least important, means of automating simulation is through application extensions.

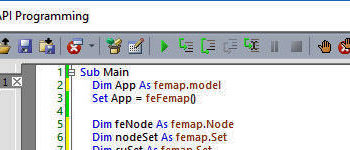

Here, a company will build out new functionality by coding software extensions to an analysis application. This is done using an Application Programming Interface (API) toolkit, which often is an externally available version of the code used to build the analysis application by the software provider.

This toolkit can be used to build brand new functionality on top of the solution. This functionality can dramatically automate simulation processes and procedures. It can add completely new interfaces such as dialog boxes and menus. It can tweak or modify how the application prepares models and passes them to solvers.

The toolkit can also be used to integrate with specialized homegrown simulation tools. Doing so allows data and other information to be passed back and forth between the applications. This is applicable when the company is dealing with custom calculations, ranging in complexity from programmed spreadsheets to their own internal software.

The value here is strong. Companies that seeking new ways to automate the simulation process has an opportunity to build it the way they want with the API. Companies with custom applications for specialize calculations can wrap their work into the simulation software.

Recap

- Companies that are looking to get more value out of simulation can look to automation, which comes in a variety of flavors.

- Macros allow users to record and then execute a sequence of actions through a trigger. This is of value to users repeatedly applying the same actions within an analysis model.

- Templates allow users to accelerate their simulation process, applying and reusing prior analysis work.

- Simulation workflows stitch the output of one analysis to the input of another, enabling the automation of several interconnected simulations.

- Application extensions add new capabilities to existing tools by coding with the software’s API toolkit. This is an opportunity for automation or integration with a company’s custom analysis application.

Automation can provide a lot of additional value to companies already leveraging analysis. What has your experience been with simulation automation? Let me know your thoughts in the comments.

Siemens PLM provides a range of capabilities that directly address automation of modern simulation processes. For more details on how FEMAP addresses these needs, download our complimentary eBook.