It’s not always planes, trains and automobiles … learn how Simcenter SCADAS RS helps other industries

In the 1987 feel-good movie “Planes, Trains and Automobiles”, Neil and Del are trying to get home from New York to Chicago. They unwillingly become travel companions when their flight is canceled due to bad weather, their train locomotive breaks down and their car is destroyed by a fire.

But back in the ’80s, the Simcenter SCADAS RS did not yet exist, otherwise, the movie would have ended much differently. Nowadays, the Simcenter SCADAS RS is used by a variety of OEM’s and suppliers from different transport industries to guarantee the reliability of their products, avoiding failures that immobilize planes, trains, automobiles and the people traveling on it.

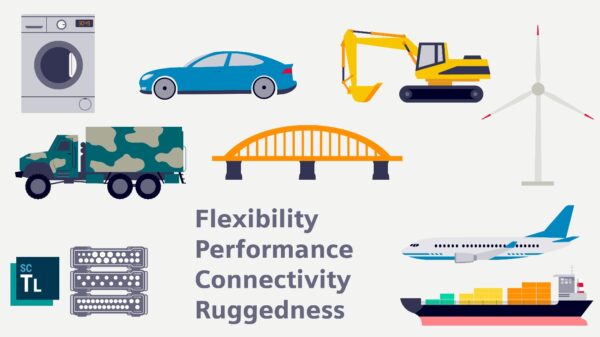

Due to its unique capabilities, the Simcenter SCADAS RS is also the perfect measurement system for some other applications outside the transportation industry.

Unique capabilities

If you want to learn more about the Simcenter SCADAS RS system, check out this page. In summary, the main capabilities are:

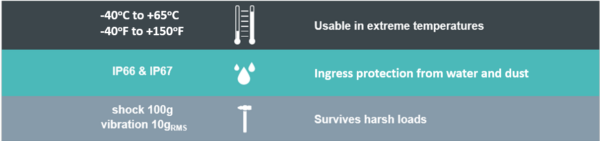

- Ruggedness: being capable of operating under a wide temperature and humidity range, resistance to heavy shocks makes it ideal to be used outside and in harsh environments.

- Flexibility: connecting directly to your laptop or using the web app from different devices such as your personal phone, tablet or laptop. In addition, the different units can be distributed in case you need to measure bigger objects such as bridges, wind turbines, buildings …

- Performance: measuring a high number of noise, vibration and durability types of sensors combined with the web app for monitoring this huge amount of data.

- Connectivity: the whole setup and measurement can be monitored from anywhere in the world, while data can be offloaded remotely for further analysis.

Bridges, boats and buildings

The above unique capabilities of the Simcenter SCADAS RS system make it the ultimate measurement equipment for a lot of other industries, some examples of existing customers are below:

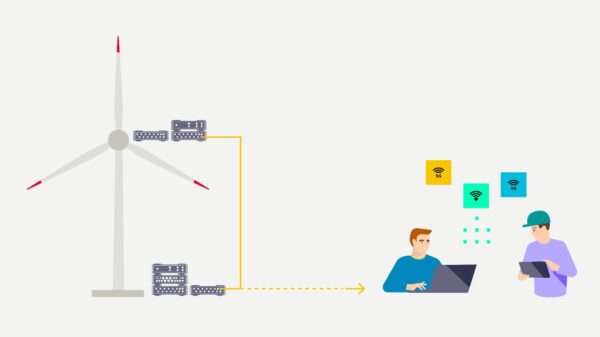

- Monitoring of vibrations and deformations on offshore wind turbines:

- distributed setup, with some units at the basement of the tower and other units in the top of the nacelle, connected via a single cable.

- automatic triggering of the measurement when exceeding predefined signal levels like wind conditions, temperatures …

- remote offloading of the data files for further analysis via the SCALANCE M modem setup.

- Marine transport of wind turbine blades:

- monitoring of vibrations during transport from the production facility to the wind park

- 4-6 weeks of data that can be used for mission synthesis analysis

- remote access to the system and data from anywhere in the world for monitoring, validation and offloading of the data

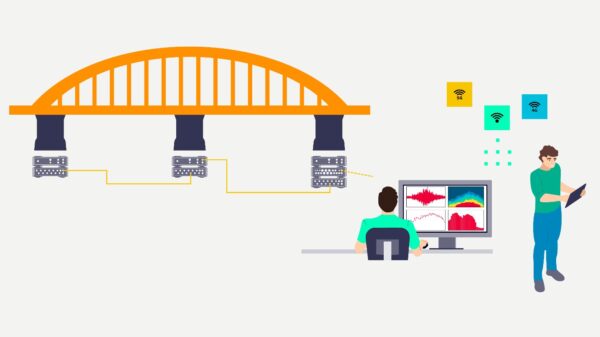

- Damage detection on bridges using operational modal analysis:

- rugged design allows placing the Simcenter SCADAS RS units outside at the pillars and deck of the bridge

- automatic data capture in loop: 10 minutes of data every 4 hours

- remote offloading of the data for operational modal analysis

- Monitoring of noise and vibration in data server rooms:

- measurement of both microphones (for environmental noise) and accelerometers (to monitor floor vibrations)

- few measurement channels per rack in a big server room make use of the distributed setup

- Monitoring and animation of building vibrations

- setup with more than 2000 sensors connected

- monitoring of the signals from a total of 16 screens thanks to the web app

Smarter and faster

Obviously, Neil and Del could have taken some smarter decisions along their journey to get home faster, but that would have spoiled a good movie plot. In the life of a test person, being smarter and faster in finishing the job is crucial! Looking at the practical testing challenges illustrated in the above industry examples, it is clear that the Simcenter SCADAS RS is the perfect fit for the job:

- faster setup and instrumentation

- each Simcenter SCADAS RS unit can be set up locally using personal devices by different people in parallel, minimizing the time to set up in (sometimes difficult) field environments

- being able to put the Simcenter SCADAS RS close to the sensor locations on big structures minimizes cable lengths, instrumentation errors, and data anomalies

- efficiency for smarter testing

- The ability to preprogram the system to trigger specific events or via remote access to an offshore wind park, ship, or distant location, being able to measure in loop, store the data locally or stream it to a PC, in parallel monitoring from different devices … the possibilities are endless and guarantee the most efficient testing for your specific situation

- In a lot of the industry examples above, having a fully reliable and rugged system under the most severe conditions of vibration, dust, humidity, and temperature is crucial

- getting validated data faster

- During the measurement you can monitor and easily check the data quality from different devices, even for 1000s of channels on big structures and even if your unit is at the other end of the world or floating on a ship in mid-ocean.

- At the moment the test schedule is finished, you have immediate access to the validated data, and can further download and post-process it in different tools: Simcenter Testlab can be used for automated further validation, in-depth post-processing like operational modal analysis, and automated reporting, while exporting to third-party files allows you to use external tools.

Now it’s your turn

Now that you know how the Simcenter SCADAS RS is fit for all of those industries, it is your turn to get smarter and faster in testing your products and make sure they do not fail when being used by your customers. From instrument setup and test preparation to actual measurements and data validation – the entire workflow is streamlined for maximum productivity, combined with the ability to withstand any test conditions, even the most extreme ones.

For more info, please check out the video above or read one of our earlier blogs.